Monitoring of fuel consumption in fuel line of engine has a number of undeniable advantages – this method of fuel control provides measurement accuracy regardless of operating conditions of vehicles, allows to monitor fuel consumption in various modes of engine operation, helps to keep track of operating time and link fuel consumption to engine hours.

Measurement of actual fuel consumption is mainly beneficial for heavy equipment: oil & gas extraction machines, mining equipment, railway, river & marine vessels, construction equipment, agricultural machinery, as well as stationary objects – diesel power plants, diesel generator sets, boilers etc.

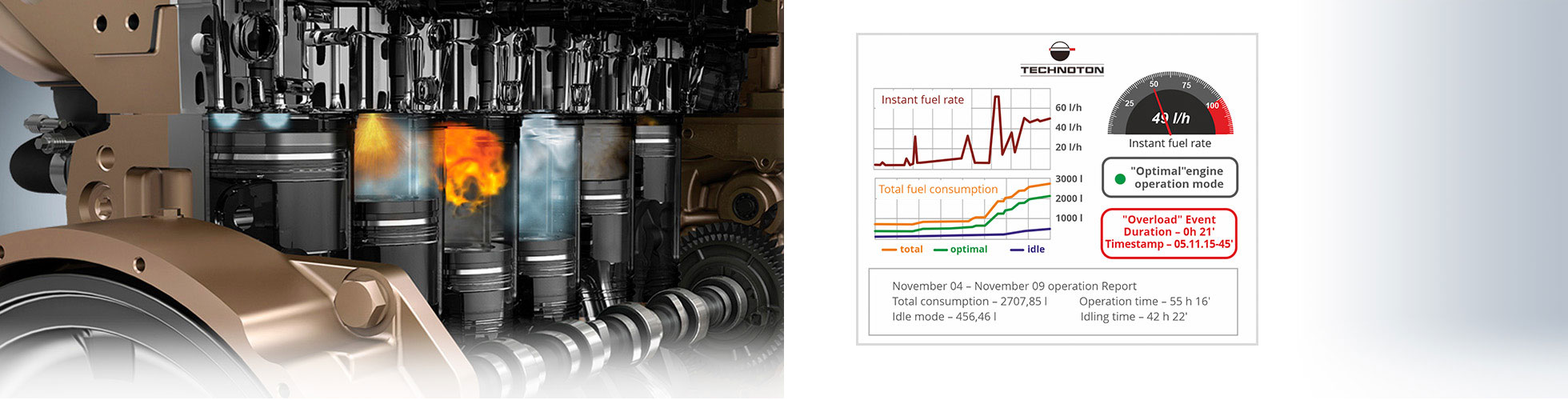

Direct fuel consumption measurement with the help of DFM fuel flow meters measures real fuel consumption by engine, and actual engine hours in various modes – idling, normal, overload.

Comparing to indirect calculation of fuel used e.g. by level change in fuel tank or by CAN bus data, DFM flow meter measures real flow rate because it is installed in supply and return lines of engine.

At the same time, fuel theft from the return line of engine and attempts of flow rate data tampering are eliminated.

Since the fuel flow meter is mounted directly to the fuel lines of engine, accuracy of measurement remains high even if the vehicle is operating at severe conditions.

Rough terrain, complicated fuel tank design, mixed engine operation cycles, short machinery operation intervals do not make any impact on fuel measuring accuracy.

DFM fuel flow meters allow monitoring 40 parameters of fuel consumption and engine operation time, which makes it possible to:

- adjust fuel quotas for certain machinery operations,

- remotely monitor deviations from normal fuel consumption and prevent breakdowns,

- keep a record of fuel system wear out e.g. example, in number of liters consumed,

- perform maintenance according to actual state and operating time.

7 advantages of Technoton DFM flow meters

- Built-in battery, independence from external power supply.

- Multilevel protection against tampering and interference.

- Event logging, allows tracking attempts of tampering.

- Wide range of models for flow rates from 1 to 25,000 l/h.

- Output interfaces: pulse, RS-232/RS-485 (Modbus RTU), CAN j1939 (S6, NMEA), S7 (Bluetooth).

- Compatible with popular GPS-rackers, detailed connection instructions are provided.

- No need of special calibration, like fuel tank calibration.