DFM fuel flow meters are designed for fuel consumption monitoring and engine operating time tracking of different applications: road transport, construction and heavy-duty vehicles, water transport, railway locomotives. They are also used for fuel consumption measurement and engine operating time tracking of diesel generators, boilers, burners and other stationary units.

As fuel flow meter is mounted directly on the fuel lines of engine, direct measurement of fuel consumption is possible even if the vehicle is operating at severe conditions. Rough terrain, complicated fuel tank design, mixed engine operation cycles, short machinery operation intervals do not make any impact on fuel measuring accuracy.

1. Fuel consumption in short operation period

During one production shift road roller has spent a small amount of fuel – the difference between fuel level at the beginning and at the end of the shift is almost invisible.

According to the data received from DFM fuel flow meter, it is possible to determine fuel consumption per hour, shift or one business day with high accuracy and fit up vehicle fleet accounting system with reliable and true to fact information.

When machinery operation intervals are short

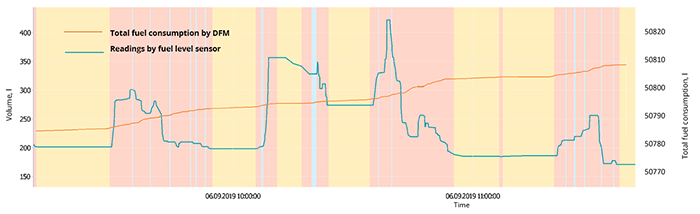

2. Fuel monitoring when fuel “bounces” inside tank

When vehicle moves in rough terrain, there is a “bumpy flight” – and fuel level in tank is not stable. Under such conditions fuel level sensor is not able to provide reliable data, that can be used for fuel consumption calculation.

DFM flow meter still demonstrates high accuracy of fuel consumption measurement and total engine operating time detection.

When vehicles are operated in rough terrain

3. Machinery operation in mixed load mode

In case heavy equipment is running on a construction site at mixed engine operation mode, DFM flow meter displays current mode and provides a breakdown by Idle, Optimal, and Overload modes.

When engine operates at mixed mode

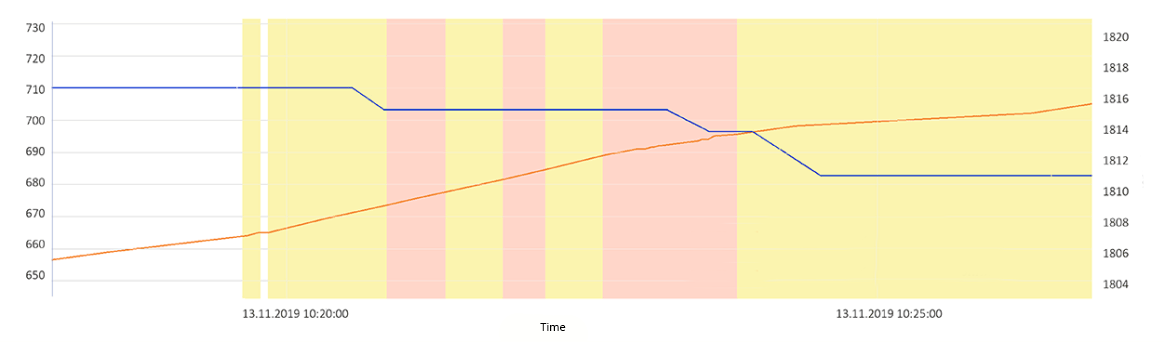

4. Remote diagnostics of fuel system

Fuel consumption got higher, and fuel flow rate in feed and return lines of the fuel system also increased. After inspecting the fuel system, clogging of fine fuel filter was detected. After fine filter changing, fuel consumption has returned back to normal conditions.

DFM fuel flow meter provides opportunity to monitor conditions of fuel system and engine health and also to carry out predictive maintenance according to engine operation modes.

Checking fuel system operation