Fuel monitoring in tall stationary tanks

- DUT-E fuel level sensors

- DFM Industrial fuel flow meters

- MasterCAN Display

- CANUp telematics gateway

Fuel monitoring in large vertical tanks

![]() Customer:

Customer:

metallurgical plant *

![]() Machinery:

Machinery:

bulk fuel storage tanks

![]() Task:

Task:

monitor fuel volume in tall vertical storage tanks,

control refueling and fuel dispensing

![]() Solution:

Solution:

- DUT-E fuel level sensors extended to 8 meters

- DFM Industrial fuel flow meters

- MasterCAN Display

- CANUp telematics gateway

![]() Result:

Result:

accurate fuel accounting in large vertical tanks,

prevention of fuel theft

The Customer

Customer is a metallurgical plant – one of the largest in Mongolia. Founded in 1994, the plant operates its own quarries for ore extraction and processing, and produces steel and cast iron (billets, rebar, cast parts).

It is also actively engaged in the procurement and recycling of scrap metal. For many years, the plant has been ranked among the top 100 enterprises in the country.

![]() 30years of successful operation

30years of successful operation

![]() 1500 employees

1500 employees

![]() 100 000tons of steel produced annually

100 000tons of steel produced annually

The Machinery

The bulk storage tanks are installed inside the hangars and span several floors, with only the top section visible

Plant operates a large fleet of specialized machinery essential for its production processes – excavators, bulldozers, dump trucks, loaders, and other vehicles.

These machines are refueled with diesel from vertical tanks located on the plant’s premises. The bulk storage tanks are housed in dedicated hangars. Each tank is 8 meters tall, 7 meters in diameter, and has a capacity of 300,000 liters.

Two pipelines are connected to each tank – one for filling the tank with fuel and another for dispensing fuel to vehicles.

The Task

Volume of fuel delivered to the tank is determined based on supplier documentation, while the fuel level is measured manually using a dipstick. The actual volumes of fuel received or dispensed are not measured.

This control method is highly inaccurate and allows for undetected fuel drainage and fraudulent activity during refueling and dispensing.

Plant’s management decided to implement a fuel monitoring system that enables:

- real-time tracking of fuel levels in the tank,

- online monitoring of fuel delivery and dispensing volumes,

- prevention of fuel theft,

- generation of analytical reports on fuel levels, refueling, and dispensing over any selected period.

Diesel from the stationary tank is used to supply

the specialized machinery operating at the plant

The Solution

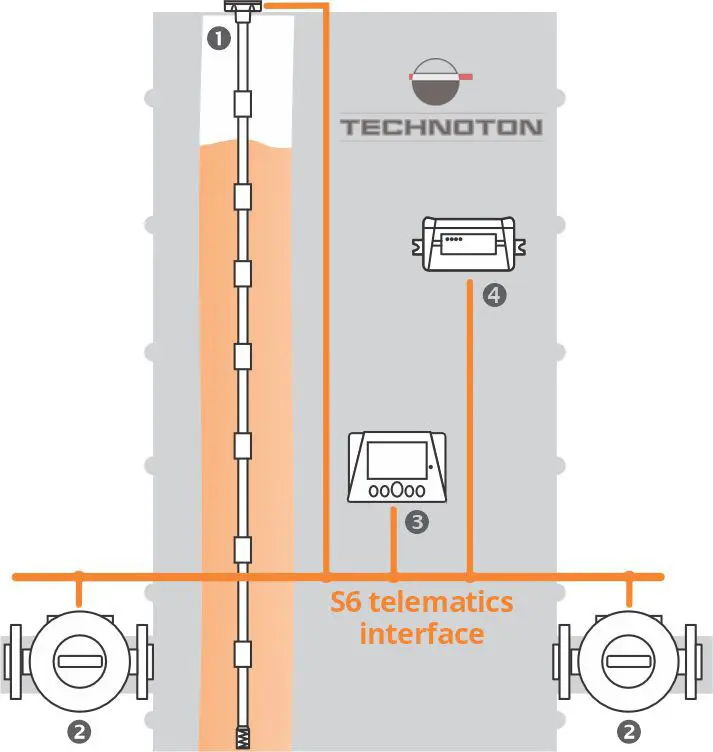

Technoton’s partner proposed a comprehensive fuel monitoring system. The system configuration is shown in the figure below.

DUT-E CAN fuel level sensor is extended to 8 meters using additional 1-meter sections. This modular design significantly simplifies transportation and installation of the sensor.

DFM Industrial CAN fuel flow meters are installed in the fuel lines to directly measure the volume of fuel delivered into and dispensed from the tank.

All equipment is connected via a cable system into the S6 telematics interface. The MasterCAN Display shows real-time fuel data, providing a convenient control tool for the operator responsible for fuel reception and dispensing.

CANUp telematics gateway collects and processes data, transmitting it to the UNUM Genset telematics platform. The platform provides online visualization of fuel metrics and generates analytical reports used by the company’s economists, accounting department, and management.

Fuel monitoring system components:

1 DUT-E CAN fuel level sensor

2 DFM Industrial CAN fuel flow meters

3 MasterCAN Display

4 CANUp telematics gateway

DUT-E level sensor extension up to 8 meters

Reports in UNUM Genset:

1 fuel volume,

2 fuel dispensing data

“Customer required precise fuel monitoring in a large-capacity tank, including tracking of refueling and fuel dispensing operations. Technoton proposed a solution: a DUT-E fuel level sensor with extension sections for level measurement, and DFM Industrial flow meters for tracking fuel movement. All data is displayed on the MasterCAN Display and transmitted to the UNUM Genset cloud platform.

We thank our partner for their professional approach and high-quality work. The equipment was installed and configured promptly, and the customer achieved their fuel control goals.”

Maksim Damarad,

Technoton Sales Engineer

The Result

Customer now receives all necessary fuel-related data — current fuel level in the tank, and the volumes of fuel filled in and dispensed. The UNUM Genset platform provides real-time data visualization and enables analytical reporting over any selected time period.

Collected data allowed the customer to establish accurate fuel accounting for this tank. Risk of fuel theft has been reduced to zero. Installation of Technoton’s fuel monitoring system on other tanks at the metallurgical plant is now being planned.

Lead specialist, Technoton partner company*

“I would like to highlight the ease of installation and connection of Technoton’s equipment. The fuel level sensor can be extended using 1-meter sections, which allowed us to quickly assemble and install it. The S6 cabling system made it easy to mount and quickly configure the entire fuel monitoring system.

Fuel data is transmitted to the UNUM Genset platform in full — without any losses or distortion.”

*Personal data is hidden from public access to comply with GDPR requirements.

Details on the project can be disclosed upon signing NDA and with the consent of our partner.