Fuel monitoring on fishing vessels

Fuel monitoring on fishing vessels

![]() Partner:

Partner:

marine electronics integration company*

![]() Machinery:

Machinery:

marine research vessel

![]() Task:

Task:

fuel consumption monitoring, integration with NMEA2000 display

![]() Solution:

Solution:

DFM S7 fuel flow meters, MasterCAN S7 NMEA data converters

![]() Result:

Result:

standardization of fuel consumption during different trawling modes and use of fishing gear

The Partner

Technoton’s partner in this project is a company with many years of experience in installation, configuration and deployment of marine electronics and IIoT solutions for maritime industry, focusing on NMEA2000 interface commonly used in marine electronics.

The Partner approached Technoton with the inquiry from one of its customers – research institute owning a fleet of marine vessels.

The Customer

The end user of the solution is one of the centres for marine research located in the EU, it’s a state scientific research institute that has been operating for over 100 years. It conducts research and development focused on studying and protecting the Mediterranean hydrosphere.

An important area of the institute’s work is fisheries research – monitoring and forecasting fish stocks, assessing water quality, and providing consultations on the management of fish resources.

The Machinery

Marine research trawler

Practical fisheries research is conducted on board of the research trawler. The vessel was built in 1986 and underwent a major modernization in 2020. The vessel is 31 meters long with a displacement of 186 tons.

Diesel engines of the vessel:

- 2 main MAN engines with a power of 350 HP each,

- 2 main generators with a power of 135 HP each,

- Emergency generator with a power of 50 HP.

The Task

On board the ship, various fishing gear is tested, and different fishing modes are simulated. Researchers are tasked with proposing optimal methods to improve the economic efficiency of fishing. One of the main parameters affecting efficiency is fuel costs.

Until 2024, the Customer did not directly measure fuel consumption. Only approximate estimates were made based on experience and engine technical documentation.

Tasks to be solved:

- accurately measure the amount of fuel consumed by the vessel

during each fishing operation, - measure fuel consumption when using different types of fishing gear,

- identify instances of fuel misuse.

Main engines of the vessel

Generators and power management control panel

The Solution

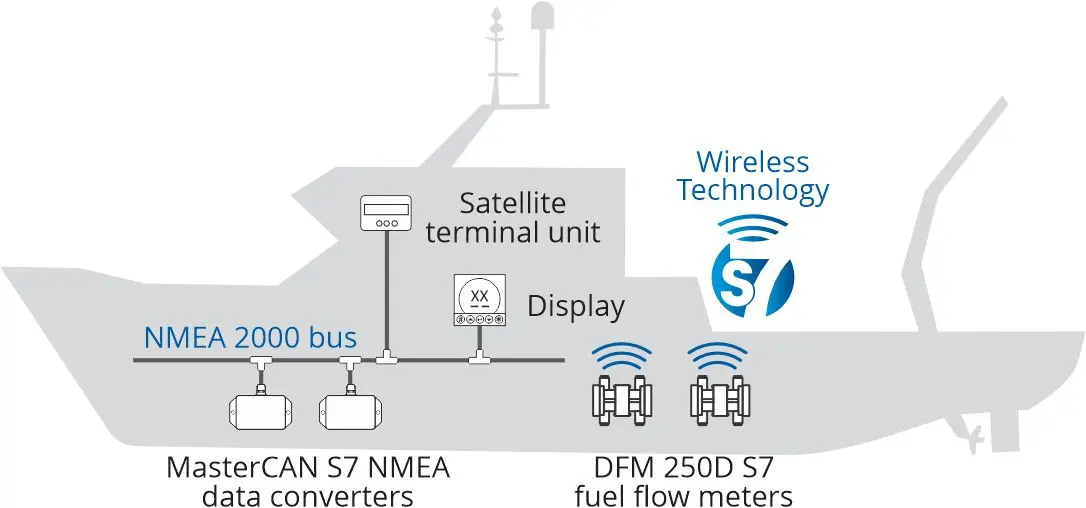

The installation of the fuel monitoring system was carried out by Technoton’s Integration partner* in the maritime sector. They offer the Customer to install a system consisting of:

- 2 DFM 250D S7 wireless differential fuel flow meters,

- 2 MasterCAN S7 NMEA data converters.

Flow meters were installed in the fuel system of the main engines. The DFM 250D S7 directly measures the flow in the supply and return lines. The data is transmitted via the wireless S7 Technology, which is based on Bluetooth Low Energy.

MasterCAN S7NMEA data converters receive the fuel consumption data, convert it into NMEA 2000 standard messages, and send it to the ship’s bus. The Simrad IS42J engine display is connected to the NMEA 2000 bus and shows real-time fuel consumption data.

Satellite terminal unit transmits data to the MaxSea navigation system. The Customer’s employees can monitor fuel consumption online and generate analytical reports for any time period.

Onboard equipment of ship fuel monitoring system

Installed DFM 250D S7

fuel flow meter

Fuel consumption displayed on Simrad IS42J engine display

Fuel consumption monitoring on marine vessels is one of the areas Technoton specializes in. Considering the need to display data on the vessel’s onboard display, we proposed installing wireless DFM S7 fuel flow meters with MasterCAN S7 NMEA 2000 data converter.

In addition to providing accurate fuel consumption data on various fuel consumers of a ship – engines, gensets, boilers – this combination of produtcs is easy to install and operate.

Kristina Pechkurenko,

Technoton Sales Engineer

The Result

The marine fuel monitoring system based on Technoton products allowed the Customer to have real data on engine consumption in various operating modes.

Daily fuel consumption is precisely determined – around 1600 liters.

Оbtained data allowed for the standardization of fuel consumption:

- for different trawling modes

- for the use of fishing gear in various conditions (load, friction,

weather conditions, and other factors)

Head of Department of the Integration company*

“To address the fuel monitoring task, we conducted a detailed market analysis and chose DFM flow meters and MasterCAN converters. Technoton produces equipment that, using the NMEA 2000 interface, can be easily integrated with displays and terminal devices from leading global manufacturers.

After the successful completion of this research project, we plan to use Technoton equipment for fuel monitoring systems in the fishing, commercial shipping, and yachting markets.”

*Personal data is hidden from public access to comply with GDPR requirements.

Details on the project can be disclosed upon signing NDA and with the consent of our partner.