Monitoring fuel consumption

and remaining volume in genset tank

Monitoring fuel consumption

and remaining volume in genset tanks

![]() Customer: energy company*

Customer: energy company*

![]() Task: fuel consumption measurement and monitoring

Task: fuel consumption measurement and monitoring

measuring remaining fuel volume in tanks of of gensets

![]() Machinery: CAT9 power generators (diesel gensets), stationary fuel tanks

Machinery: CAT9 power generators (diesel gensets), stationary fuel tanks

![]() Solution: DUT-E 2Bio fuel level sensors, DFM D fuel flow meters

Solution: DUT-E 2Bio fuel level sensors, DFM D fuel flow meters

![]() Result: automated fuel supply from storage to gensets,

Result: automated fuel supply from storage to gensets,

fuel costs reduced by 15%

The Customer

Smart Power Chile is a company specialized in complex electronic and electric engineering solutions. The company designs and deploys power generation systems fore remote objects. Power generation systems by Smart Power Chile are successfully operated in mines, livestock farms, fishing villages, national parks. After installing and launching the equipment, Smart Power Chile carries out optimization of power generation and diesel fuel use at the object.

Headquarters of the company is located in Santiago, Chile. Installations are carried out in Chile, Argentina and other Latin American countries.

The Machinery

Power generation for remote objects is done by 3-4 diesel generators. All gensets are supplied with fuel from one 30,000-liter stationary storage.

CAT C9 diesel generators are used. Engine – 6 cylinders, volume is 8,8 liters. Electrical power is 230-330 kVA, three-phase current 400V/50 Hz. Fuel injection system – MEUI (Mechanical Electronic Unit Injection), structurally similar to Common Rail.

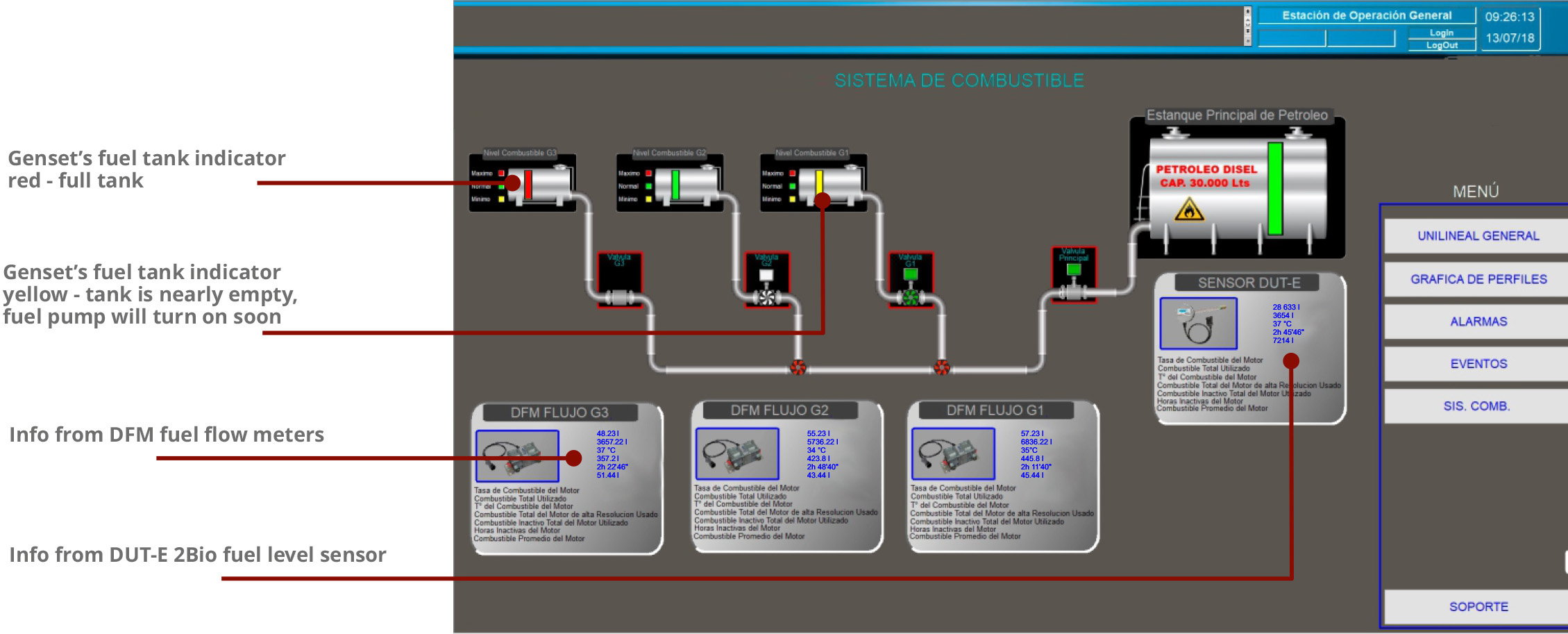

Fuel supply system consists of stationary storage, common fuel line and fuel pumps, which pump fuel out of storage and pump it in fuel tanks of each single diesel generator.

Fuel supply system

Monitoring fuel consumption and remaining volume in tank

The Task

Smart Power Chile had two interconnected tasks:

- automate refilling of fuel tanks of generators and exclude human factor;

- monitor fuel consumption and operation time of diesel generators.

Calculated fuel consumption quota of a genset according to specification is 43 L/h to 59 L/h depending on engine operation mode.

Before installing Technoton fuel monitoring equipment, fuel consumption was measured and accounted using tables, where engine operation intervals in various workloads were written down manually. High accuracy result was not possible to reach using that method. Thus, it was not possible to get precise numbers on fuel consumption and get accurate fuel volume balance in a tank of a genset.

Fuel pumps, which are refilling fuel tanks of gensets, were switched on manually by operator. The decision on when to turn on a fuel pump and how long it should work was done by the operator, who was relying on own experience and understanding of current situation at the object. In case of wrong decision, unexpected emptying of fuel tank would lead to genset stop and sudden interruption of power supply to the object.

The Solution

Fuel volume in stationary storage is measured by DUT-E 2Bio fuel level sensor with RS-485 Modbus RTU interface. The sensor has additional measuring electrode, which allows to measure fuel volume in tank regardless of fuel type inside (mineral diesel or biodiesel) with high precision – inaccuracy is 0,2% while sensitivity of measurement is 0.1mm. Operator can visually follow fuel volume in storage. If fuel is nearly over – the operator sends inquiry for storage refueling.

In fuel system of each genset DFM 500D differential fuel flow meters with RS-485 Modbus RTU interface are installed. Flow meters send data on instant and total fuel consumption, operation time of gensets’ engines in various operation mode – in total 46 Parameters and Counters.

DUT-E 2Bio fuel level sensor and DFM fuel flow meter are integrated with SCADA. SCADA control system makes calculations on remaining fuel volume in each diesel generator’s tank, based on fuel consumption data and operation time of fuel pump. If remaining fuel volume is at its minimum – fuel pumps are automatically turned on. The operator can also monitor remaining fuel volume in each fuel tank on SCADA panel.

Fuel control in the SCADA software package

Alexandra Cherednichenko, Technoton account manager

«The customer wanted to automate refiling of diesel generators’ fuel tanks. Technoton offered the following solution – make automatic calculations in SCADA on the basis of accurate info on fuel consumption of each genset. Fuel is measured by DFM 500D fuel flow meters and DUT-E 2Bio fuel level sensors.All equipment sends data via RS-485 Modbus RTU protocol. That allowed to carry out easy integration with installed SCADA control system and get detailed information on fuel consumption, fuel temperature and engine operation time in various work modes.»

The Result

Technoton’s equipment for fuel monitoring allowed to automate fuel supply from fuel storage to fuel tanks of individual gensets. By excluding human factor, a risk of genset’s engine stop due to empty fuel tank is eliminated. Fuel consumption and operation time in various work modes are also monitored automatically. Gathered information allowed customer to optimize engine operation and reduce fuel costs by 15%.

Tecnoton’s products support data transfer using Modbus RTU protocol. That allowed to embed fuel level sensors and fuel flow meters into SCADA control system, which is generally used by Smart Power Chile. No further equipment for signal collection and processing, as well as no additional software for data analysis were needed – that allows to reduce total price of fuel monitoring system for genset owners.

Victor Hugo Romero,

power engineer

«Before installing Technoton's equipment, fuel consumption and genset operation time data were gathered and processed manually. Reliability and accuracy of the data were doubtful.DFM fuel flow meters automatically send accurate data on fuel consumption to the database and after that fuel consumption and remaining fuel volume are visualized in SCADA system.

Technoton is the only company, which was able to offer us both fuel flow meters and fuel level sensors sending data over Modbus RTU protocol.

We’re going to continue installing Technoton’s products with Modbus RTU protocol in similar projects.»

«Before installing Technoton's equipment, fuel consumption and genset operation time data were gathered and processed manually. Reliability and accuracy of the data were doubtful.DFM fuel flow meters automatically send accurate data on fuel consumption to the database and after that fuel consumption and remaining fuel volume are visualized in SCADA system.

Technoton is the only company, which was able to offer us both fuel flow meters and fuel level sensors sending data over Modbus RTU protocol.

We’re going to continue installing Technoton’s products with Modbus RTU protocol in similar projects.»

Victor Hugo Romero,

power engineer