MasterCAN DAC Digital-to-analog converter is an intelligent device for converting digital messages of the J1939 protocol into analog signals, and at the same time analog signals of voltage, frequency, current into J1939/71.

A distinctive feature of MasterCAN DAC is support of than 10,800 parameters (SPN) of CAN J1939/71 protocol. This allows you to easily find the desired parameters in CAN bus when converting to analog signals, and also gives you freedom of choice when determining the target parameter (SPN) to which you want to convert the analog signal.

What does the digital-to-analog converter MasterCAN DAC do?

MasterCAN DAC converters purpose of use

Basically, MasterCAN DAC digital-to-analog converter is used in vehicle telematics, remote monitoring of the operation of diesel generators, and automation of gensets.

MasterCAN DAC solves both general monitoring tasks and niche ones:

- Output of digital fuel level sensor data to the input of vehicle analog dashboard, or conversion of analog level sensor signal into CAN J1939 digital messages and further transmission to dashboard, controller or other CAN gateway device.

- Additional protection for people and equipment. For example, blocking the fuel tanker pump control relay in motion.

- Remote blocking of vehicle engine (immobilizer through the ignition key);

- Remote start of diesel generator engine;

- Automation of fuel transfer from the storage tank to the supply tank of diesel generator.

Digital-to-analogue converters in vehicle telematics

Digitization of signals from analog sensors of equipment is a common task in telematics, especially for special equipment for oil and gas, agricultural machinery, railway and other complex machines.

Complex machines have dozens of analog sensors – pressure, temperature, level, condition (“closed-open”) and others. Also, this is typical for older technology, where digital interfaces are used to a lesser extent or not used at all.

Data from analog sensors is needed in a telematics system to monitor performance of machinery, monitor condition of units, and control operating conditions of machines.

Without a digital-to-analog converter, you will have to use GPS tracker with many analog inputs. For 2022, there are few such terminals left, because most manufacturers have switched to digital interfaces, and the cost of such trackers is much higher than those equipped with CAN input only.

The opposite situation often happens – the need to convert digital data from CAN bus or additional sensors into analog signals for output to the instrument panel or transmission to GPS tracker for monitoring that is not equipped (or is already occupied by other equipment – for example, a tachograph) CAN port.

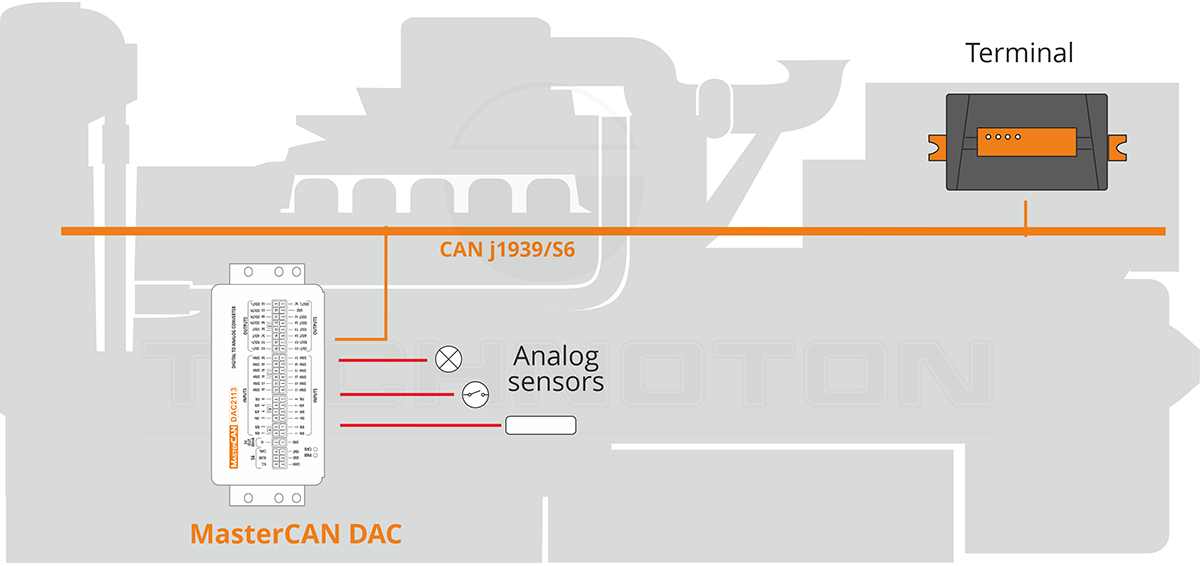

Digital-to-analog converters in industrial Internet of things (IIoT) and industrial automation

As for monitoring the operating parameters of stationary machines and installations – diesel generators, boiler and furnace equipment, mini-gas stations and others – the use of MasterCAN DAC converter (adapter) is similar to the use in vehicle telematics.

The difference comes when it comes to automation. MasterCAN DAC allows switching relays for controlling units of stationary installations using analog output signals that are generated when a corresponding CAN message appears at the input.

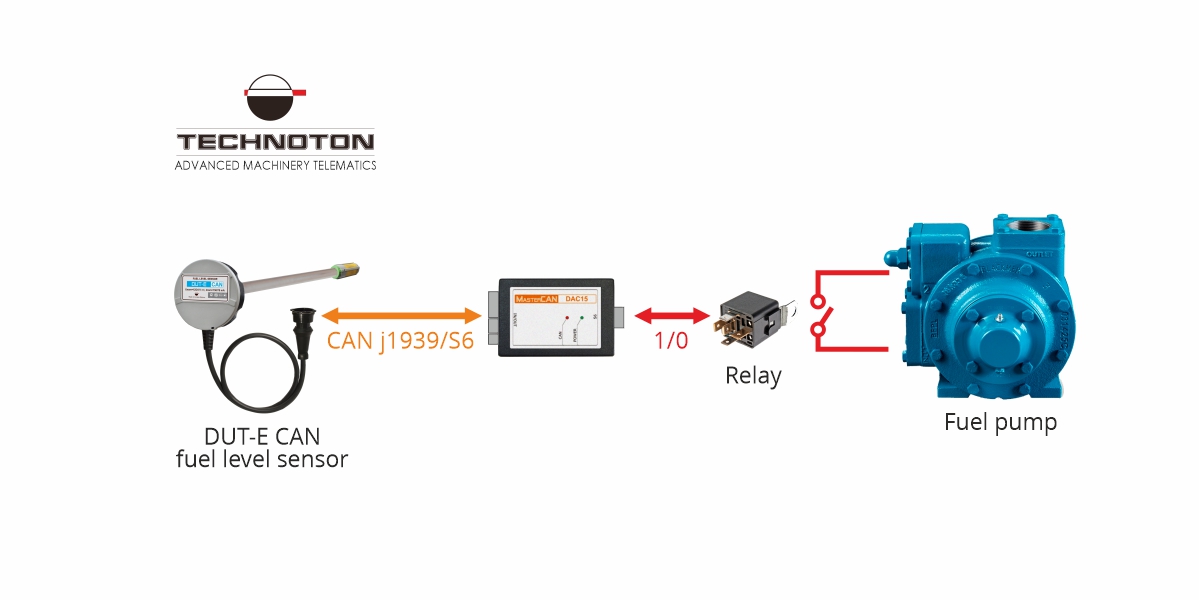

For example, DUT-E CAN fuel level sensor is installed in the genset supply tank, which sends data to both CANUp telematics gateway and MasterCAN DAC converter. When the fuel level drops to 15% (or another value selected by the installer), MasterCAN DAC sends an analog signal and closes the relay for controlling the fuel pump, which pumps fuel from the storage tank into the supply tank of generator. Fuel is being transferred, which will end when the level of 90% in the supply tank is reached – MasterCAN DAC will send a signal to open the pump control relay.

Main advantages of MasterCAN DAC

Overview of settings for MasterCAN DAC converters

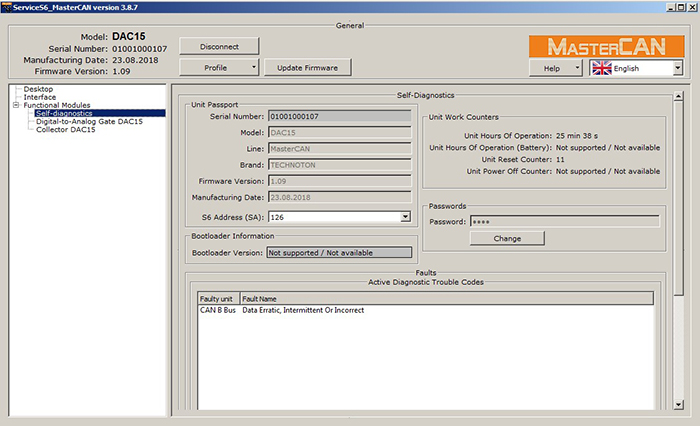

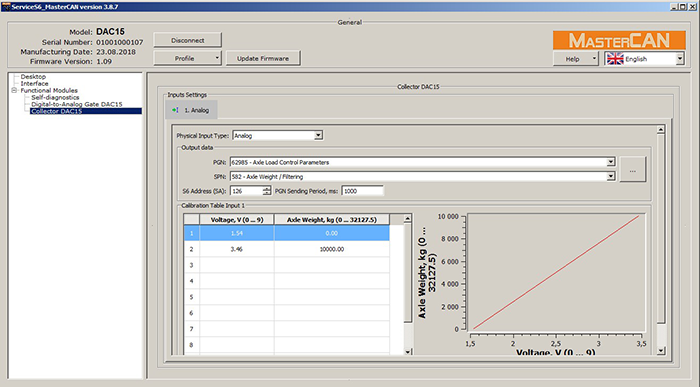

MasterCAN DAC is configured with a special software utility Service S6 MasterCAN and S6 SK service kit via K-Line (SAE 14230) interface

In software interface, it is possible to select CAN protocol, indicate the address on S6 (SA) bus, select the exchange rate via CAN, turn on/off the terminal resistor.

Self-diagnostics mode is intended for user authorization, identification of MasterCAN DAC passport data, accounting of operating time, as well as active and detected faults.

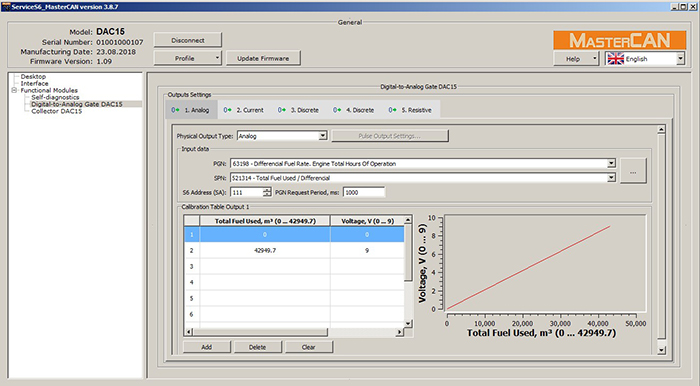

Digital-to-Analog gate mode provides settings of MasterCAN DAC analog outputs according to parameters (SPN) received from vehicle CAN bus messages (PGN).

The list of priority SPN for MasterCAN DAC contains most important vehicle operation parameters from vehicle telematics point of view: fuel level and volume of the fuel tank; temperature (oil, fuel, coolant, ambient, etc); pressure (oil, fuel); fuel consumption; engine RPM; speed; power supply voltage; axle load and etc.

Collector mode provides parameter settings (SPN) of output PGN messages of MasterCAN DAC15 according to received analog input signal. For example, you can set up an axle load calibration table depending on the pressure in the pneumatic circuit.

Examples of using MasterCAN DAC converters

Let’s consider several examples of configuring MasterCAN DAC digital-to-analogue converters.

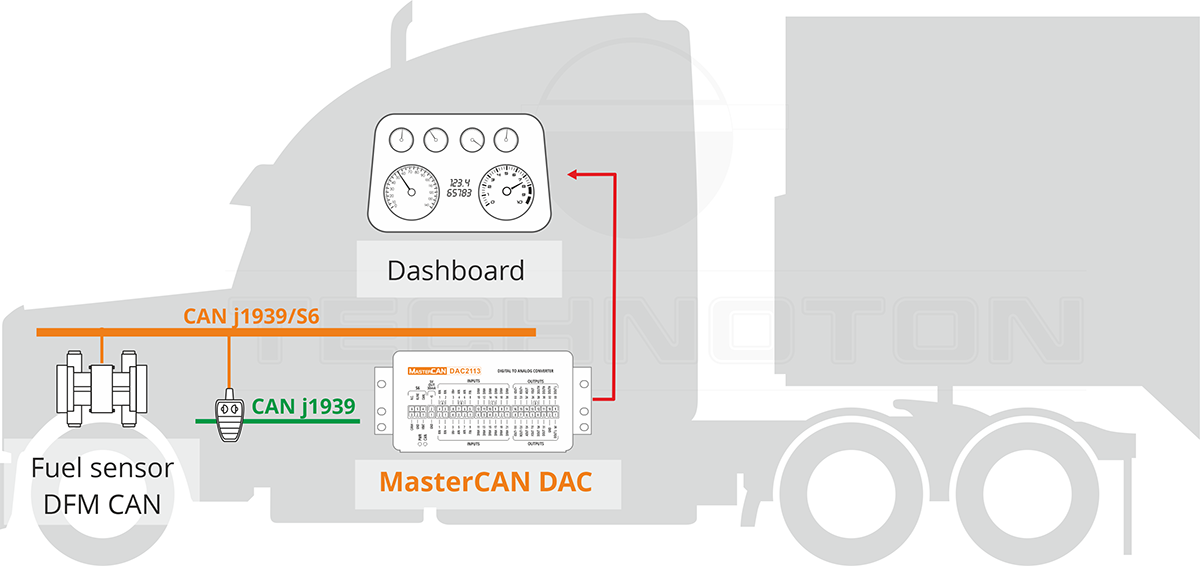

1. Transferring data from DUT-E CAN digital fuel level sensor to dashboard

This situation arises when the accuracy of standard fuel sensor in fuel tank doesn’t work for vehicle owner, and at the same time, fuel control system with additional level sensor and telematics unit is already installed on vehicle. Also, this situation occurs during the assembly of buses and other equipment, where DUT-E is used as a standard sensor, but the dashboard does not have a CAN input.

We install DUT-E CAN in fuel tank and make a calibration table – see DUT-E CAN manual.

- Connect DUT-E CAN to CAN/S6 interface of MasterCAN DAC15, connect power to DUT-E CAN and MasterCAN DAC. After that, we connect resistive output of MasterCAN DAC15 to the dashboard of vehicle. We look at the pinout of the converter in the MasterCAN DAC manual, the pinout of the dashboard – in the documentation for the dashboard or on the back of the panel itself.

- We launch Service S6 MasterCAN software and go to the menu item “Digital-analog gateway DAC15”, select the tab “5. Resistive” area of the screen “Physical output settings”.

- In “Input data” screen area, you need to select PGN 62982 “Filtered level and volume of fuel in the tank” – click on the square button marked “…” (three dots), enter PGN number or name, find the required package, click “OK”. From the drop-down list of the “SPN” line, select either 521023 “Fuel level / filtered value” (then the resistive signal will correspond to the level in millimeters), or 521024 “Fuel volume in the tank / filtered value” (then the resistive signal will correspond to the volume in liters).

- In the area of the screen “Calibration table for Output 5” we enter into the table the data from the calibration table compiled for the tank.

- We press “Profile” button (the upper part of the software screen, the “General Information” area), then – “Save to Unit”.

The setup is completed, we do a control drain-fill and check the correctness of data on dashboard.

2. Diesel Generator Refueling Automation

Diesel generator has its own supply tank, in which a fuel control system with a DUT-E CAN level sensor is already installed or it is planned to install one.

Fuel in the supply tank of diesel generator comes from external storage tank (which is also used by other gensets at the same facility). MasterCAN DAC and a set of relays will be used to control a pump that transfers fuel from a storage tank to a specific generator tank.

- (If level sensor is not yet installed in genset fuel tank) Install and connect DUT-E CAN, make a calibration table for genset fuel tank. We combine DUT-E CAN and MasterCAN DAC15 using S6 Technology (CAN j1939/S6-interface) – see DUT-E CAN and MasterCAN DAC manuals.

- Relays are connected to the power supply circuit of fuel pump motor. The relays will turn on and off fuel pump according to control signal of MasterCAN DAC outputs. MasterCAN DAC converter will turn on the pump through a relay when fuel level drops to a critical level (for example, 15% of total fuel tank volume) and turn off the pump when the tank is 90% full.

- In MasterCAN service S6 software, select PGN “Filtered level and volume of fuel in fuel tank”, then the required SPN. The choice is volume in liters or percentage, level in millimeters. It is recommended to select fuel volume as a percentage so that in the future you can copy MasterCAN DAC tuning profile to automate other diesel generators.

- Compile a calibration table for the first discrete output. In this table, all points of fuel volume above 15% will correspond to the value of the output signal “0”, and below 15% – the value of the output signal “1”.

- Compile a calibration table for the second discrete output. In this table, all points of fuel volume above 90% will correspond to the value of the output signal “1”, and below 90% – the value of the output signal “0”.

- Setup is completed. We save settings profile to MasterCAN DAC memory, perform a control drain and check the correct operation of fuel supply system.