![]()

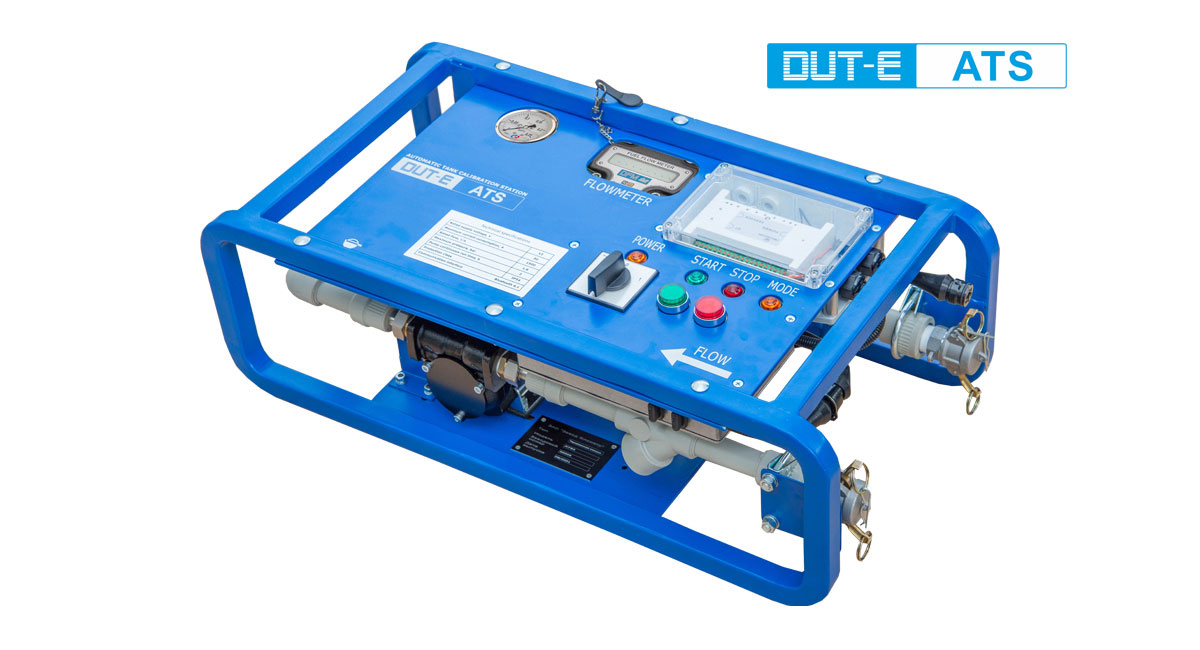

Automatic Tank Calibration Station

DUT-E ATS automatic calibration station is used by telematics technicians for calibrating fuel tanks of vehicles and stationary machinery, where fuel monitoring is done by additional accurate fuel level sensors.

DUT-E ATS accelerates the process of installing a fuel monitoring system and allows creating a highly accurate calibration table (surpassing manual tank calibration), while reducing the risk of mistakes.

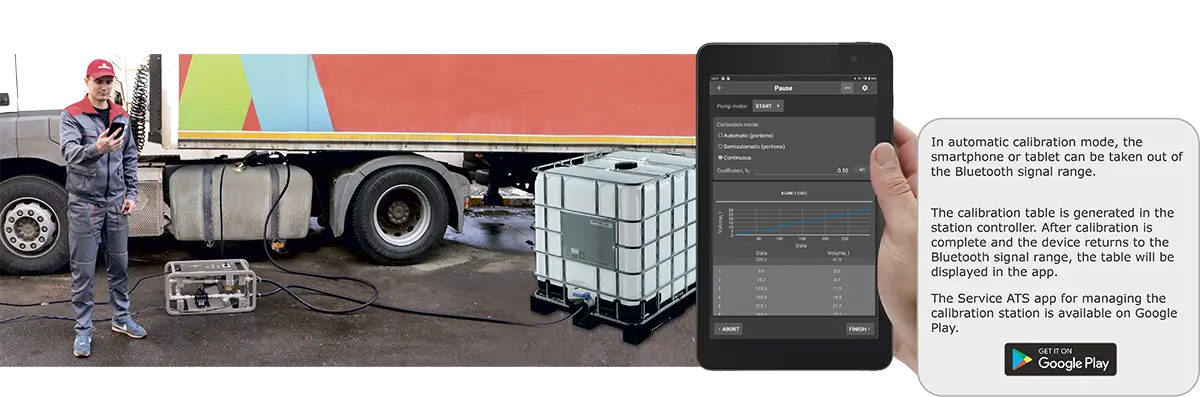

Automatic mode of DUT-E ATS brings the most results — once the station is launched, a technician can tackle other tasks and get back when calibration is finished. Automatic mode is available for DUT-E fuel sensors.

Advantages of using DUT-E ATS

- 2-3 times quicker installation of fuel monitoring system;

- accurate tank calibration: 57 points, inaccuracy ±0.5% of tank volume;

- exclusion of the “human factor” and possible mistakes;

- calibration of complex tanks equipped with up to 5 sensors;

- auto shut-off when pressure or temperature is exceeded;

- quick-detachable connections for fuel hoses;

- control using a smartphone via Bluetooth;

- self-diagnostics of station operation during calibration.

Tank calibration modes in DUT-E ATS

The DUT-E ATS calibration station operates in the following modes:

- continuous (except for DUT-E A5 and DUT-E A10) — the station continuously pumps fuel, adds points to the calibration table at regular intervals (portions). Suitable for standard fuel tanks.

- automatic — the station pumps fuel in portions, waits until the fuel level stabilizes and adds the point to the table, then pumps the next portion of fuel. Suitable for tanks of complex shape with bulkheads.

- semi-automatic – the station transfers fuel in portions. The user monitors the stabilization of the fuel level and manually restarts the pump. After each pump activation, a new point appears in the calibration table.

Compatibility of the DUT-E ATS Calibration Station with Fuel Level Sensors

Fuel Level Sensors by Technoton:

DUT-E, DUT-E S7, DUT-E 2Bio, DUT-E GSM

The DUT-E ATS calibration station is fully compatible with all models of DUT-E fuel level sensors and operates in all modes: continuous, automatic, and semi-automatic.

![]()

Third-Party Fuel Level Sensors:

Analog/Frequency output

RS-232 / RS-485 interface (LLS protocol)

CAN interface (SAE J1939 protocol)

With third-party fuel level sensors, the DUT-E ATS calibration station operates in semi-automatic mode.

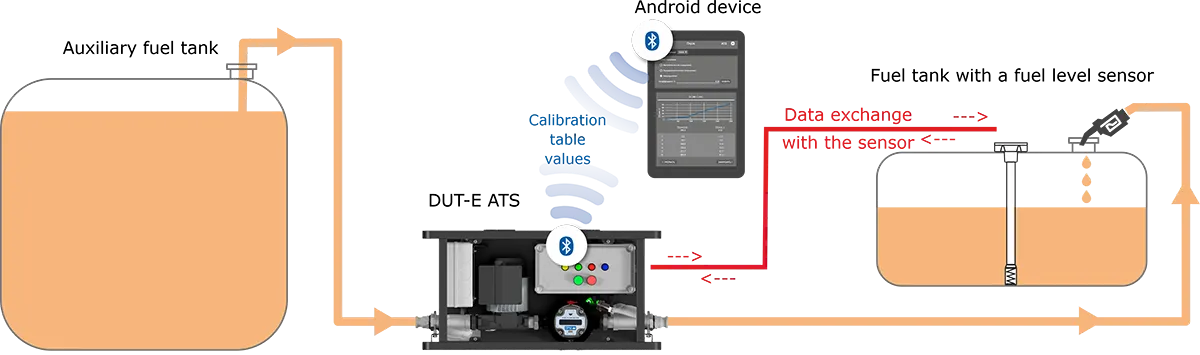

The operating principle of the DUT-E ATS calibration station.

- After the station is started, the fuel pump automatically transfers fuel from the auxiliary tank to the calibrated tank through the built-in DFM Marine fuel flow meter.

- According to the volume value preset in the Service ATS mobile application (Android), the tank is automatically divided into 57 calibration points.

- The fuel volume values (DFM Marine readings) and the corresponding fuel level values in the tank (fuel level sensor readings) are transmitted via Bluetooth to the mobile application.

- The station generates a calibration table based on this data and builds a graph showing the relationship between fuel volume and fuel level in the tank.

- Once the calibrated tank is filled, the calibration procedure is automatically completed. The generated calibration table is saved both to the sensor’s memory and to a file.

Specifications

| Working fluid | Diesel fuel | |

| Calibration relative error limit, % of tank volume, not more | ±0.5 | |

| Continuous operating time | Unlimited | |

| Input interfaces for connecting wired sensors | RS-232 (2 pcs.) / RS-485 (2 pcs.) / CAN (1 pc.) / K-Line (2 pcs.) | |

| Physical signal inputs for sensor connections | Analog / frequency (2 pcs.) | |

| Calibration modes | Automatic, semi-automatic, continuous | |

| AC power supply voltage, V/Hz | 230/50 | |

| Power consumption, W, not more | 400 | |

| Fuel transfer speed, L/h | 3500±200 | |

| Range of ambient temperature, °C | -10…+30 | |

| Maximum hydraulic pressure in pipeline, MPa | 0.29 | |

| Weight with hoses, kg, not more | 29±2 | |