Liquid counters

LC Liquid Counters are high-precision devices for measuring consumption of non-aggressive liquids within a kinematic viscosity range of 0.5 to 3000 mm²/s (cSt), designed for high-power units in water transportation, energy, petrochemical industry, as well as industrial and municipal sectors.

LC can function as standalone flow measurement devices or be integrated into industrial automation systems, stationary object monitoring, machinery telematics, and Industrial Internet of Things (IIoT) solutions.

Accurate liquid flow measurement

Accurate liquid flow measurement Recording operating time of a pump or fuel consumer

Recording operating time of a pump or fuel consumer Prevention of liquid theft from pipelines

Prevention of liquid theft from pipelines Monitoring of liquid temperature and density

Monitoring of liquid temperature and densityLC Gear

Oval gears, for stationary installations and auxiliary ship equipment

- Flow range, L/min: 12 … 416

- For non-agressive liquids 0.55 … 300 cSt

- Operating fluid temperature (°C): –20 … +90

LC Ring

Ring-piston, for heavy-duty land and rail machinery, and small vessels

- Flow range, L/min: 0.33 … 66

- For diesel fuel and heating oil 1.1 … 6 cSt

- Operating fluid temperature (°C): –40 … +95

LC Corio

Coriolis (mass and volumetric), for marine applications and industrial pipelines

- Flow range, L/min: 7 … 6,705

- Operating fluid viscosity (cSt): 0.5 … 3000

- Operating fluid temperature (°C): –60 … +100

Advantages of LC liquid counters

- High measurement accuracy – from ±0.15%, essential for flow monitoring in industrial and energy facilities.

- Wide viscosity range – suitable for various non-aggressive liquids from 0.55 to 3,000 cSt.

- Versatility – power generation, petrochemical industry, heavy-duty machinery, marine transportation, as well as municipal and industrial sectors.

- Model variety – flow measurement from 0.33 to 6,700 l/min, available in both standalone and interface-enabled versions.

- Real-time data control – display on a built-in screen and transmission to recording devices (terminals).

- System integration – compatible with local industrial automation systems and online remote monitoring platforms (IIoT).

- Reliability and durability – designed for operation in harsh conditions of heavy machinery and industrial systems.

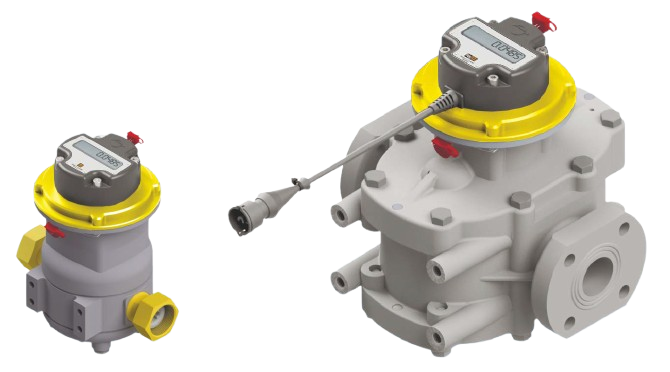

LC Gear liquid counter

Fluid consumption metering for stationary installations and auxiliary ship equipment.

The product’s appearance in images may vary

and does not affect its specifications or quality

LC Gear counters are used for measuring consumption of light petroleum products, primarily diesel fuel (including marine diesel), heating oil, and non-agressive fuel additives.

The LC Gear series counters are use for metering total consumption of liquid fuel, recording total operating time of the flow, measuring volumes of dispensed liquids.

Application

- High-power diesel gensets, heaters

- Fuel delivery trucks and fuel tankers

- Petrochemical production

- Power generation units of ferries, tugs, medium-size ships

- Power generation units of railway equipment

- Fuel transfer and dispensing systems (fuel stations)

Design advantages

Measuring chamber with oval gears

High measurement accuracy across a wide range of viscosities

Informative digital display

Over 15 operating counters, local data monitoring

Built-in battery

Autonomous operation and data storage without external power

Variety of interfaces

CAN J1939, pulse, Bluetooth Low Energy

Specifications

| Model | LC Gear 120 | LC Gear 410 |

|---|---|---|

| Minimum liquid flow rate, L/min | 12 | 41 |

| Maximum liquid flow rate, L/min | 120 | 416 |

| Relative error, max, % | 0,25 | |

| Viscosity of the working liquid, mm²/s (cSt) | from 0.5 to 30 (calibrated at production) | |

| Maximum working liquid temperature, °C | 90 | |

| Maximum working liquid pressure, Mpa | 1,6 | |

| Interfaces | CAN j1939, pulse, RS-485 (optional converter) | |

| Ingress protection rating | IP 54 (IP67*) *аvailable on request | |

| Types of connection | flanged, threaded | flanged |

| Weight, not more than, kg | 5,4 | 14,6 |

Data on display and in output interface

- Total liquid consumption

- Total operating time of counter

- Liquid consumption by operating modes

- Counter operating time by modes

- Liquid consumption (clearable)

- Counter operating time (clearable)

- Temperature in measuring chamber

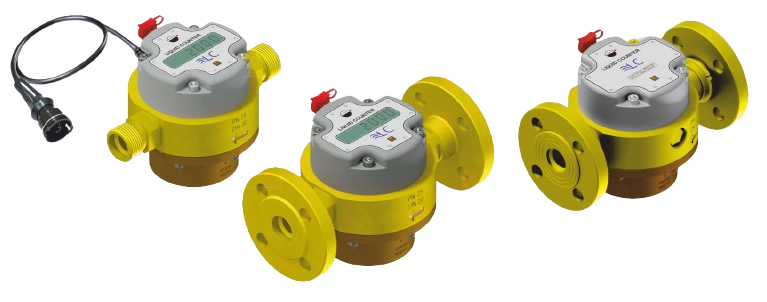

LC Ring liquid counter

Metering fuel usage of heavy-duty vehicles and small vessels

Application

- Mining dump trucks, excavators, bulldozers

- Heavy-duty special equipment in oil and gas industry

- Shunting locomotives, track maintenance machines

- Tugs, small and medium work vessels, ferries

- Diesel generator sets, boiler and heating systems

Design advantages

Ring-type measuring chamber

Simple, reliable design

Informative digital display

Dozens of parameter screens and operation counters

Variety of models

Autonomous, wired (CAN, Modbus, pulse), wireless (BLE)

Built-in battery

Autonomous operation and data storage when external power is off

Specifications

| Model | LC Ring 15 | LC Ring 30 | LC Ring 65 |

|---|---|---|---|

| Minimum liquid flow rate, L/min | 0,33 | 0,66 | 1,33 |

| Maximum liquid flow rate, L/min | 16,5 | 33,00 | 66,00 |

| Relative error, % | no more 0,5 | ||

| Viscosity of liquid, mm²/s (cSt) | from 1,5 to 6,0 | ||

| Maximum liquid temperature, °C | 95 | ||

| Maximum liquid pressure, bar | 25 (flanged) / 16 (threaded) | ||

| Interfaces | autonomous, CAN j1939, pulse, wireless (Bluetooth) | ||

| Types of connection | flanged or threaded | ||

| Weight, not more than, kg | 4,3 | 6,3 | 9,3 |

Data on display and in output interface

- Total liquid consumption

- Total operating time of counter

- Liquid consumption by operating modes

- Operating time by modes

- Liquid consumption (clearable)

- Operating time (clearable)

- Temperature in measuring chamber

LC Corio liquid counters

Metering fuel oil and petroleum products used in large marine vessels and industrial pipelines

The product’s appearance in images may vary

and does not affect its specifications or quality

LC Corio liquid counter operates based on the Coriolis principle, allowing both mass and volumetric measurement of liquid flow. The liquid passes through a tube with virtually no flow resistance.

LC Corio is used for various types of liquid fuels, including marine fuel oil, technical water, and other non-aggressive liquids. Its applications are diverse, ranging from marine transport to industrial facilities.

Fields of application

- Marine engines and diesel generators

- Oil & gas and chemical industries

- Fuel dispensing systems

- Diesel power plants

- Boiler installations

Data on display and in output interface

- Mass flow rate

- Volume flow rate

- Liquid temperature

- Liquid density

- Total mass and volume consumption counters

Specifications

| Model | Mass flow rate, t/h | Volume flow rate, L/min | Nominal diameter, mm |

|---|---|---|---|

| LC Corio 95 | 0,35 – 5,2 | 7 – 100 | 15 |

| LC Corio 380 | 1,3 – 20 | 25 – 380 | 25 |

| LC Corio 1200 | 4 – 65 | 77 – 1240 | 50 |

| LC Corio 2300 | 10 – 120 | 192 – 2300 | 80 |

| LC Corio 3800 | 27 – 200 | 514 – 3800 | 100 |

| LC Corio 6700 | 30 – 350 | 575 – 6700 | 150 |

Liquid temperature range …………………………………….. from –60 to +100 °C

Operating pressure range …………………………………………… from 0 to 4 MPa

Accuracy volume / mass ………………………..±0,21% / ±0,16% for diesel fuel

Output interface ………………………………………………… RS-485 (Modbus RTU)

Pipeline connection ………………………………………………………………… flange

Design advantages

- High measurement accuracy

- Suitable for pipelines of any configuration

- Resistant to vibration, temperature, and pressure fluctuations

- Capable of measuring high-viscosity liquids

- Long service life and low maintenance requirements

Transferring data to IIoT platform or telematics server

Liquid/fuel usage data on the display of LC counters

All LC liquid counter models feature an information display showing real-time measurement data.

The information on the display can be used as the main way of gathering data and writing it down into a ledger, or as an extra way of local monitoring by technical team.