![]()

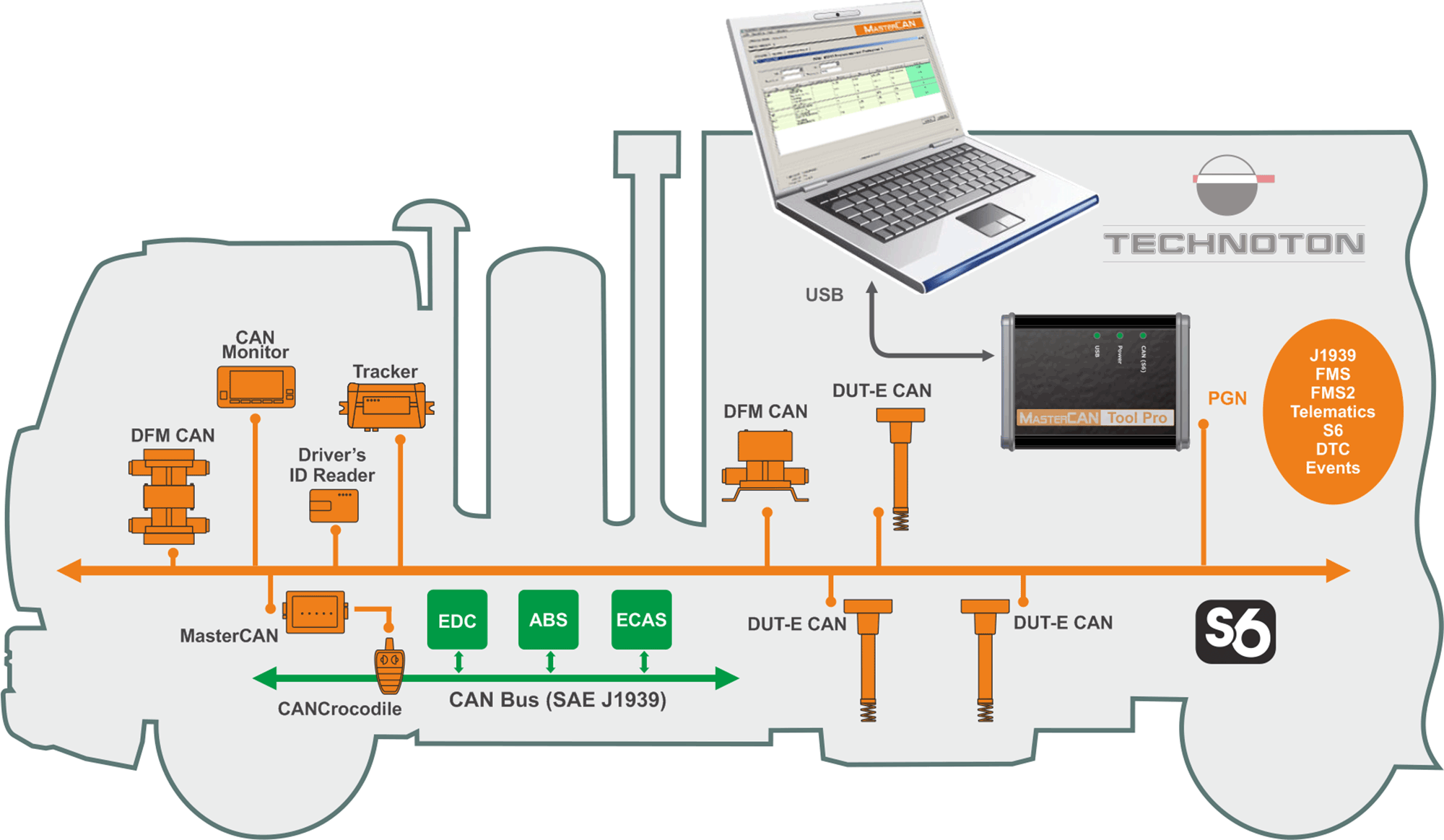

CAN bus analyzer – simulator

MasterCAN Tool is a powerful software-and-hardware CAN SAE J1939 analytical tool for engineers, programmers and other professionals in the area of design and servicing vehicle electronic units, telematics systems and onboard equipment – fuel sensors, trackers, gateways.

MasterCAN Tool is designed for CAN SAE j1939 data monitoring, analysis as well as PGN message emulation and modelling. MasterCAN Tools is also used for CAN j1939/S6 Telematics interface diagnostics and configuration.

Main tasks solved by MasterCAN Tool:

- design, configuration and testing CAN bus telematics equipment (SAE J1939 standard for data exchange)

- CAN message analysis, automatic parsing and storing data logs when connected to standard vehicle CANbus

- reading and identification of electronic control units (ECUs) malfunctions (DTC)

- monitoring operational status of equipment employing S6 Technology

Advantages of MasterCAN Tool

- Parsing and displaying PGNs and SPN names and measurement units as text

- Displaying current values of parameters (SPN) in decimal and HEX formats

- Recording values of parameters to a file (logging)

- Emulation of individual PGN with SPN that can be edited or creation of PGN groups and their transmission to CAN bus

- Allows selection between 11/29 bit length identifiers during CAN message emulation

- Configurable send/receive data baud rate – 100/125/250/500/1000 kbit/s

- Simple, easy and safe connection to CANbus with CANCrocodile contactless reader

- An option to enable the terminal resistor of CAN bus using software

- CAN bus load indicator

- Power supply from USB of PC or vehicle’s onboard electrical network

Monitoring telematics equipment operation with MasterCAN Tool

MasterCAN tool provides data exchange between on-board equipment and PC via CAN j1939/S6 Telematics interface. Special software is used for data reading and analysis.

| Parameter, measuring unit | Value |

| Nominal supply voltage, V | 9/45 |

| Current consumption at nominal supply voltage 12 V/24 V, mA | not more than 200/100 |

| Operating ambient temperature, °C | -10…+60 |

| Ingress protection rating | IP40 |

| Overall dimensions, mm | 114х85х35 |

| Weight, kg, not more | 0,3 |

| Communication interface with the Vehicle CAN bus or CAN j1939/S6 Telematic interface CAN | CAN 2.0В |

| Communication interface with PC | USB |

| Functional Features | MasterCAN Tool Lite | MasterCAN Tool Pro |

| Reception of PGN from CAN bus (SAE J1939) or using S6 Technology and their display as detailed SPN. | + | + |

| Modeling PGN raw data with parameters set by the user (test messages). | + | + |

| Emulation of individual PGN with SPN that can be edited or creation of PGN groups and their transmission to CAN bus(SAE J1939) or using S6 Technology. | – | + |

| Saving/opening for editing the file of the created PGN groups and test messages. | * | + |

| Data entry/opening the data log (log file) for the analysis of data received from CAN bus (SAE J1939) or using S6 Technology. | + | + |

| Update of the inbuilt software (firmware update) of MasterCAN Tool Adapter. | + | + |

| Adjustable CAN bitrate (SAE J1939) or using S6 Technology. | + | + |

| Enabling CAN bus terminal resistor with software. | + | + |

| Selection of ID length 11 bit/29 bit in the mode of PGN raw data modeling. | + | + |

| Indicator of CAN bus current load. | + | + |

| * MasterCAN Tool Lite has a feature of saving/opening only for test messages. | ||

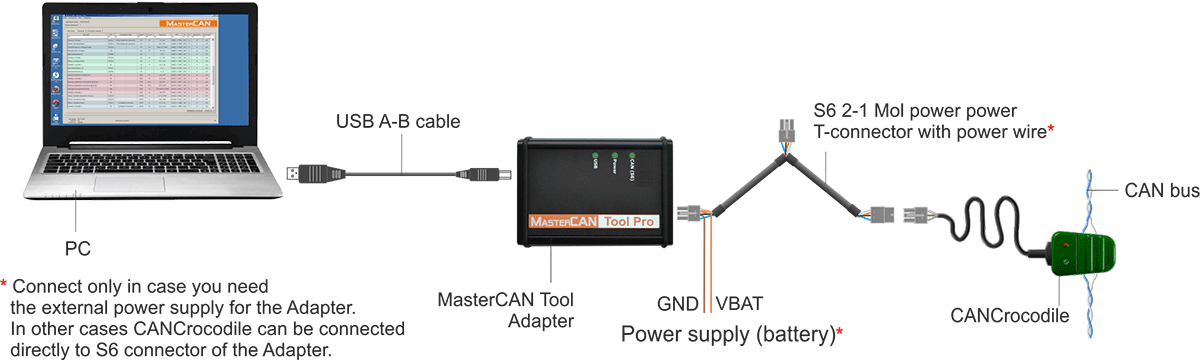

a) contactless connection with CANCrocodile

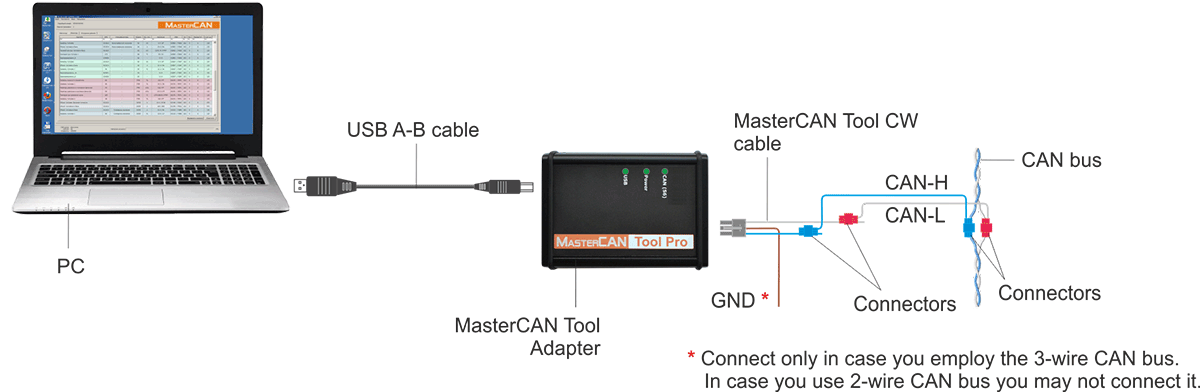

b) contact connection with MasterCAN Tool CW cable

b) contact connection with MasterCAN Tool CW cable

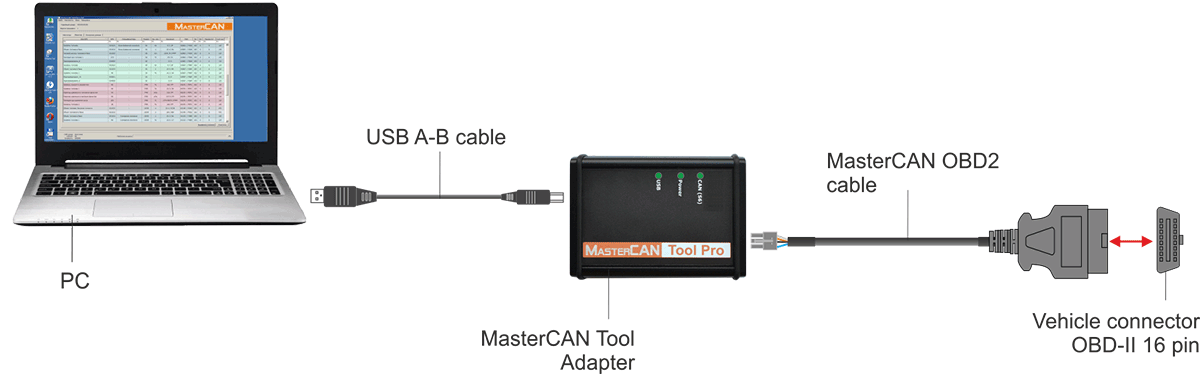

c) contact connection with MasterCAN Tool OBD2 cable

c) contact connection with MasterCAN Tool OBD2 cable

d) contact connection with MasterCAN Tool J1939 cable

d) contact connection with MasterCAN Tool J1939 cable

For monitoring PGN received from CAN bus (SAE J1939) or using S6 Technology you should open the Monitor tab. This tab allows you to view and analyze in real time SPN of all received PGN which comply with SAE J1939 Standard.

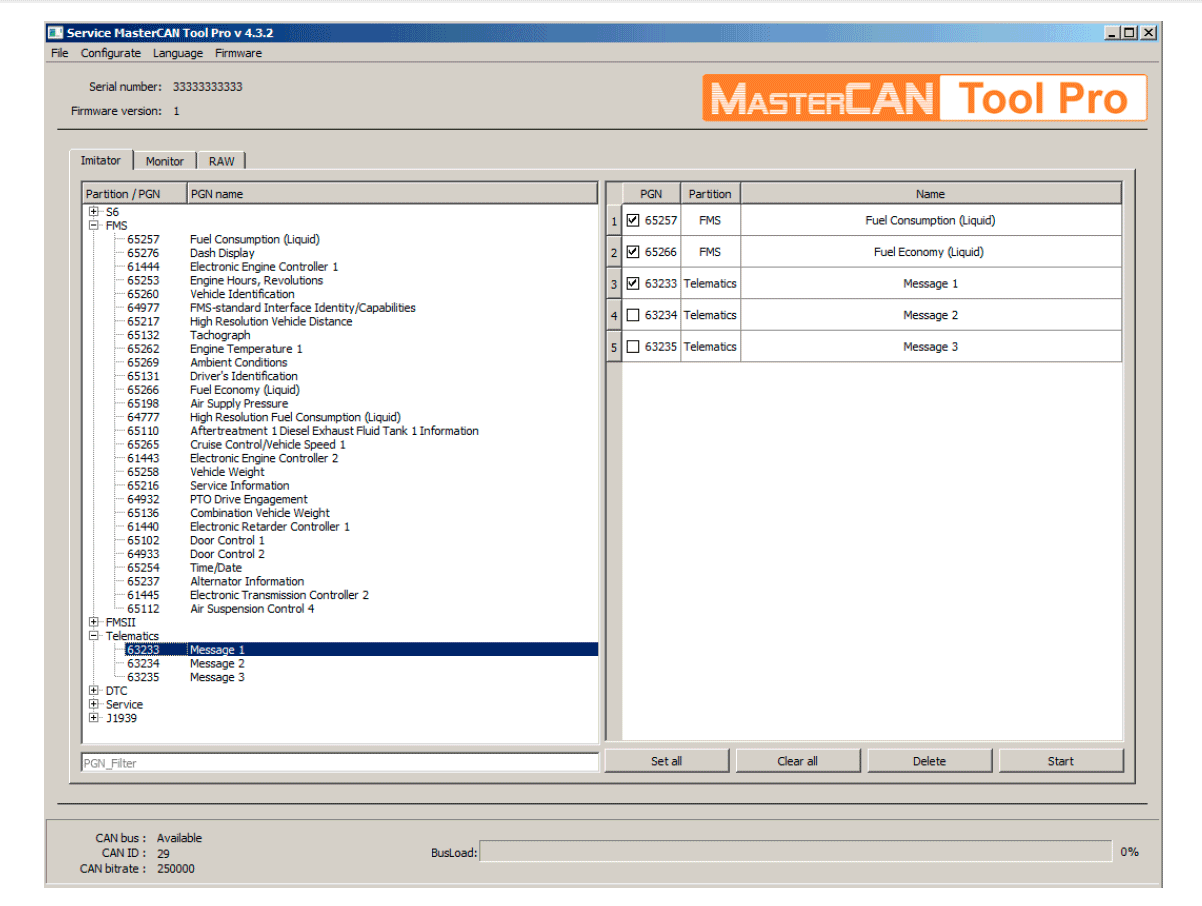

Imitator tab allows transferring PGN from the list of set into CAN Bus (SAE J1939) or using S6 Technology.

In PGN editors of S6, FMS, FMSII, Telematics, J1939 sets SPN numeric values are available for editing.

In PGN editors of S6, FMS, FMSII, Telematics, J1939 sets SPN numeric values are available for editing.

The RAW tab is designed to create and transmit user (test) PGN to CAN bus or using S6 Technology and to monitor and carry out detailed analysis of user (test) and all other PGN received from Units using S6 Technology or from CAN bus with a possibility to view their ID (CAN_ID) and raw data (DATA).

The RAW tab is designed to create and transmit user (test) PGN to CAN bus or using S6 Technology and to monitor and carry out detailed analysis of user (test) and all other PGN received from Units using S6 Technology or from CAN bus with a possibility to view their ID (CAN_ID) and raw data (DATA).