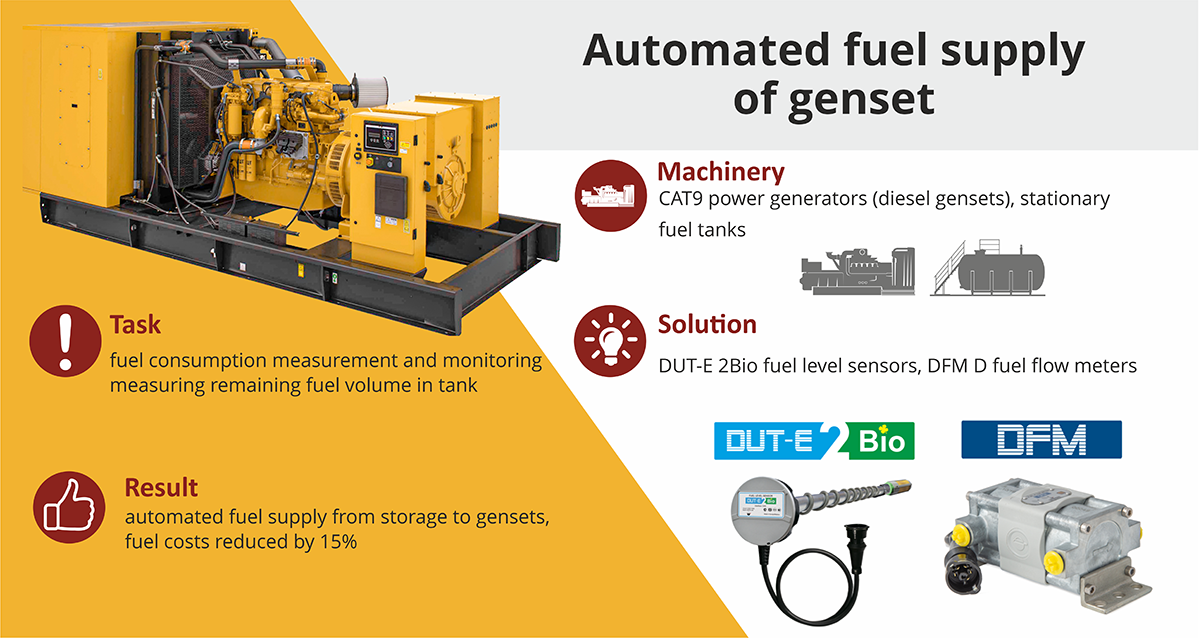

The company, specialized in complex electronics, which designs and deploys power generation systems for remote objects, faced the necessity of ensuring uninterrupted fuel supply of genset. As a result of diesel generator telematics implementation, unexpected emptying of fuel tank and sudden stop of generator’s engines were excluded, fuel costs were reduced by 15%.

Discover how the project was solved.

The Machinery

3-4 CAT C9 diesel generators with 6 cylinders engine, 8,8 liters in volume. All gensets are supplied with fuel from one 30,000-liter stationary storage.

The Solution

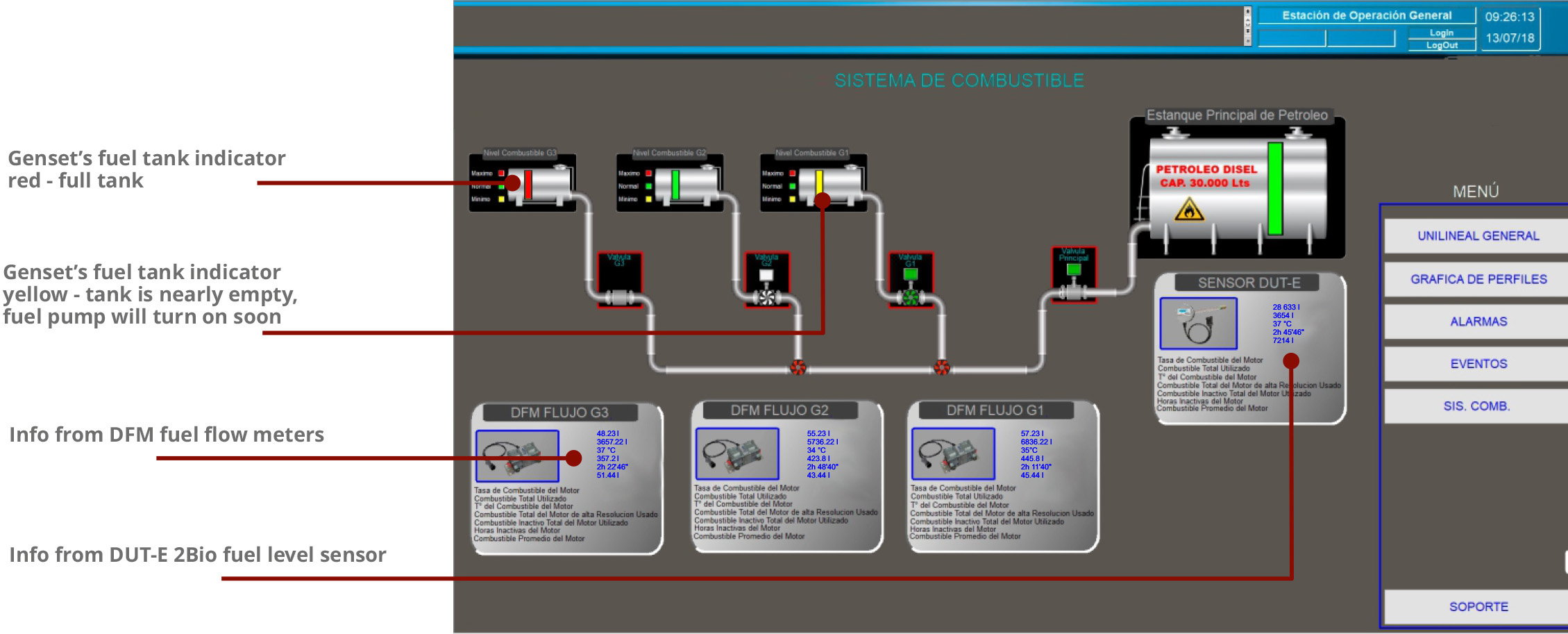

Fuel volume in stationary storage is measured by DUT-E 2Bio fuel level sensor with RS-485 Modbus RTU interface. In fuel system of each genset DFM 500D differential fuel flow meters with RS-485 Modbus RTU interface are installed.

DUT-E 2Bio fuel level sensor and DFM fuel flow meter are integrated with SCADA. SCADA control system makes calculations on remaining fuel volume in each diesel generator’s tank, based on fuel consumption data and operation time of fuel pump. If remaining fuel volume is at its minimum – fuel pumps are automatically turned on. The operator can also monitor remaining fuel volume in each fuel tank on SCADA panel.