Genset network fuel consumption

monitoring and efficiency

Genset network fuel consumption

monitoring and efficiency

![]() Customer:

Customer:

energy consulting service company

![]() Task:

Task:

fuel management and costs reduction on generators

![]() Machinery:

Machinery:

diesel generators network for banks

![]() Solution:

Solution:

DFM fuel flow meters + tracking device

![]() Result:

Result:

1) fuel costs reduction up to 30%,

2) monitoring of engine load and working hours

Customer

Customer’s company provides services in energy consulting and fuel management to find the best way for clients to lower fuel costs and increase efficiency. Their clients from bank sphere have large network of generators.

Customer’s company utilizes a CORE Analysis that investigates the issues and probes deeper to uncover base causes within the company. That analysis is centered on the four areas of Revenue, Finance, People and Technology. Customer prepare a recommendation to address the critical issues discovered and suggest appropriate solutions and their business impact and the pricing for us to engage our partners.

Machinery

Permanent supply of electricity is the basis for bank’s uninterrupted operation, guaranteeing timely financial transactions and security of deposits.

In the electrical network of African countries, there are frequent power outages. Diesel generators are used for backup power supply.

By technical characteristics optimal choice is CAT generators. In the bank field diesel generator power rating 810 kVA (50 Hz, 1500rpm, 400V).

Fuel Consumption:

- 100% load with fan – 171.7 L/hr

- 75% load with fan – 130.4 L/hr

- 50% load with fan – 90.9 L/hr

Task

Most Nigerian businesses rely on diesel-powered generators because of the poor electricity infrastructure. That is why bank industry has large network of own generators to ensure uninterrupted services to their clients. For bank industry it is essential to stay online when commercial power fails. Keeping an eye on multiple remote generators across a region can get complicated as each generator may start its operation at different times, and consume fuel at different rates.

Fuel monitoring is a huge concern for mobile or stationary generators that are used to provide back-up power. The important task is to monitor generator operation time and its fuel economy.

The client assigns the task to equip generators with remote monitoring system of fuel consumption to be able to get the following information:

- Generator hours run.

- Fuel consumption at all engine modes (idling, optimal and full load).

- Battery voltages.

- Temperature trends.

- Power quality and RPMs.

The task is to monitor all this data remotely in real time to reduce maintenance costs and prevent fuel thefts.

Solution

DFM fuel flow meters are mounted into engine system to measure total fuel economy, hourly fuel consumption, also engine working hours and fuel temperature. Besides, that total fuel monitoring system gives the client possibility to know about generator power, battery voltage and rpm. It is possible to set up email notifications about any rapid changes. In this case differential fuel flow meter was used – DFM 500D with CAN interface.

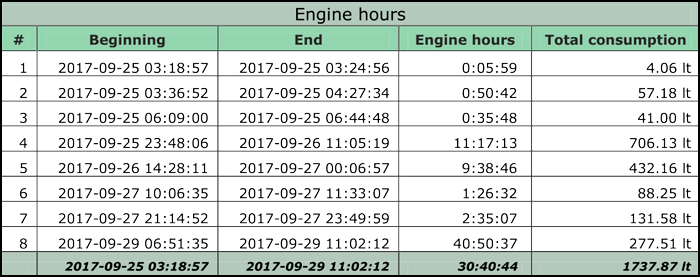

DFM 500D CAN allows to get messages remotely for feed and reverse fuel flow rates separately, net fuel consumption of engine and fuel temperature in real time. Also, CAN interface allows to send ready parameters in liters (gallons) that makes 99% accuracy of fuel measurement and display data on server. Each DFM fuel flow meter has option of recording modes of engine operation and performs self-diagnostics to detect interference into system and prevent fuel theft. The following online reports were created for the client.

DFM 500D – Differential fuel flow meter

Report “Fuel consumption and Engine hours”

Report in ORF4 telematics service

Report “Total Statistics”

Report in ORF4 virtual dashboard

Irina Poyankova, Technoton

“We proposed DFM fuel flow meter for generators application because it is easy and high accurate way to monitor fuel consumption. Differential fuel flow meter doesn’t require to change engine system, plus CAN interface of the device give much more parameters for a customer than any other digital or impulse flow meters. Generators automatically starts working and it is important to know about exact time of engine running time and fuel consumption during that exact time and location.”

Result

After DFM fuel flow meters and monitoring system are deployed in generators, the client can control full generator working conditions, fuel economy and fuel theft. It saves money on maintenance costs, optimizes fuel economy up to 30% – up to $1100 monthly.

All data is available remotely – it saves time and money whenever it is necessary to get back to generator’s location to know about fuel used, load, battery voltage etc.

Real time monitoring of generator performance reduces sudden downtime, overall maintenance cost and fuel consumption. If it falls, timely actions can be taken to bring performance back to acceptable level.

Customer’s company representative*

“Fuel usage monitoring with inbuilt DFM fuel flow meters allows the client to save good money and take full control of equipment. Reporting on fuel usage and generator’s operation in real time via Internet, notifies on generator’s malfunctions, draining and refilling of fuel, consumption tampering via SMS and e-mail – all this allows us to set up really profitable solution for a client.”

*Data is hidden from public access to comply with GDPR requirements. Details on the project can be disclosed upon signing NDA and with the consent of our partner.