RAILROAD MACHINERY MONITORING

Remote technical monitoring of locomotives

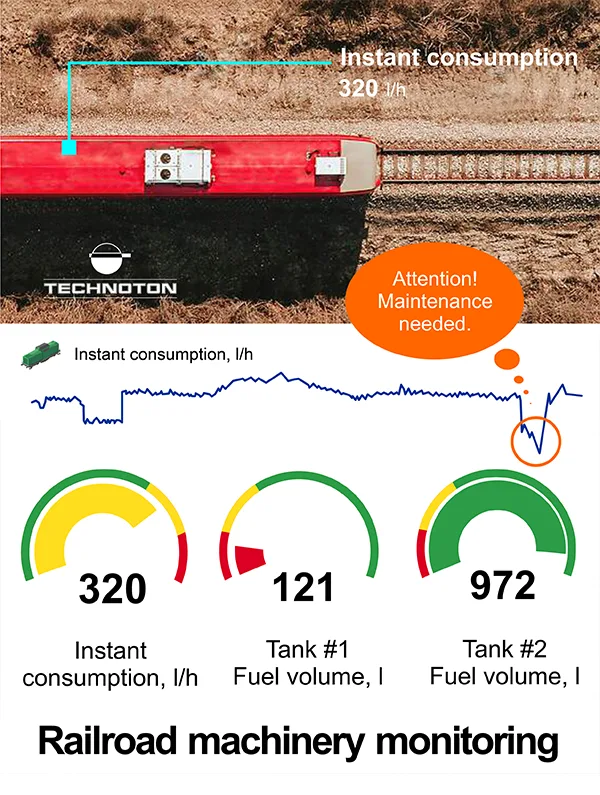

Railroad telematics system is used for remote monitoring of operational parameters of locomotives and railway machinery: fuel consumption measurement, fuel tank fill-up and draining detection, monitoring of remaining fuel volume in tank; recording total operation time of each engine (genset) in “Heating up” and “Optimal” work modes; diagnostics of engine’s error codes and malfunctions, condition of fuel system and other units of the machinery.

Monitoring of railroad machinery allows to adjust fuel consumption quotas, prevent fuel theft from tanks and fuel lines, reduce unproductive and excessive fuel consumption, schedule refueling of locomotive’s fuel tanks.

Remote diagnostics of engine(s) provides the opportunity to implement a predictive maintenance approach, which means carrying out technical maintenance of machinery “just in time: repair of fuel system and other equipment, replacement of fuel filters, engine oil and other consumables taking into account actual wear.

Telematics system set

Telematics system set

Events, parameters and reports

Parameter monitoring

- Fuel consumption and operation time of main and reserve gensets in various operation modes – warming-up, normal load mode.

- Accurate volume and temperature of fuel in main and feed tanks, also total volume of fuel.

- Data from standard CAN bus and CAN j1939/S6 interface – temperature, level and pressure of liquids.

- Mileage between current maintenance.

- Onboard power supply voltage

- Engine operating time in “Tampering”/“Interference” mode

Event detection

- Drain/Fillings of fuel, genset start/stop.

- Fuel consumption tampering, engine failures and malfunctions.

- Event notification via SMS and e-mail.

Used products

Usage cases

Railroad track, Latvia

Task: fuel consumption monitoring.

Solution: DFM fuel flow meter and offline terminal.

Railway machinery manufacturing plant

Task: fuel tank monitoring.

Solution: DUT-E fuel level sensors, MasterCAN DAC converters.

Fuel and engine monitoring on a railway snowplow

Task: onboard monitoring of fuel tank, fuel consumption and engine status

Solution: DUT-E fuel level sensors, DFM D CAN fuel flow meters, MasterCAN CAN2RS data converters.