Remote fuel storage monitoring

Monitor fuel level remotely, track the volumes of fuel received and dispensed from fixed tanks and cisterns.

Tasks solved by fuel storage monitoring system

Tasks solved by fuel storage monitoring system

Fuel monitoring in storage tanks and cisterns is essential for smooth running of diesel generators, power stations, vehicle fleet fuel depots, agricultural activities, construction and mining sites, and marine and river ports.

The main purpose of monitoring fuel storage is to get accurate real-time data on the volume of fuel left, fuel consumption and tank replenishing. Remote fuel control helps to keep an eye on fuel usage patterns, prevent unauthorized draining (fuel theft), and eliminates the need for manual fuel level checks.

This method greatly cuts down on fuel costs, strengthens financial security, and reduces the risk of harming the environment. It also helps set up better fuel delivery systems and avoids issues caused by fuel shortages.

Advantages of Technoton monitoring solution for stationary tanks

Information available in Technoton stationary tank monitoring system

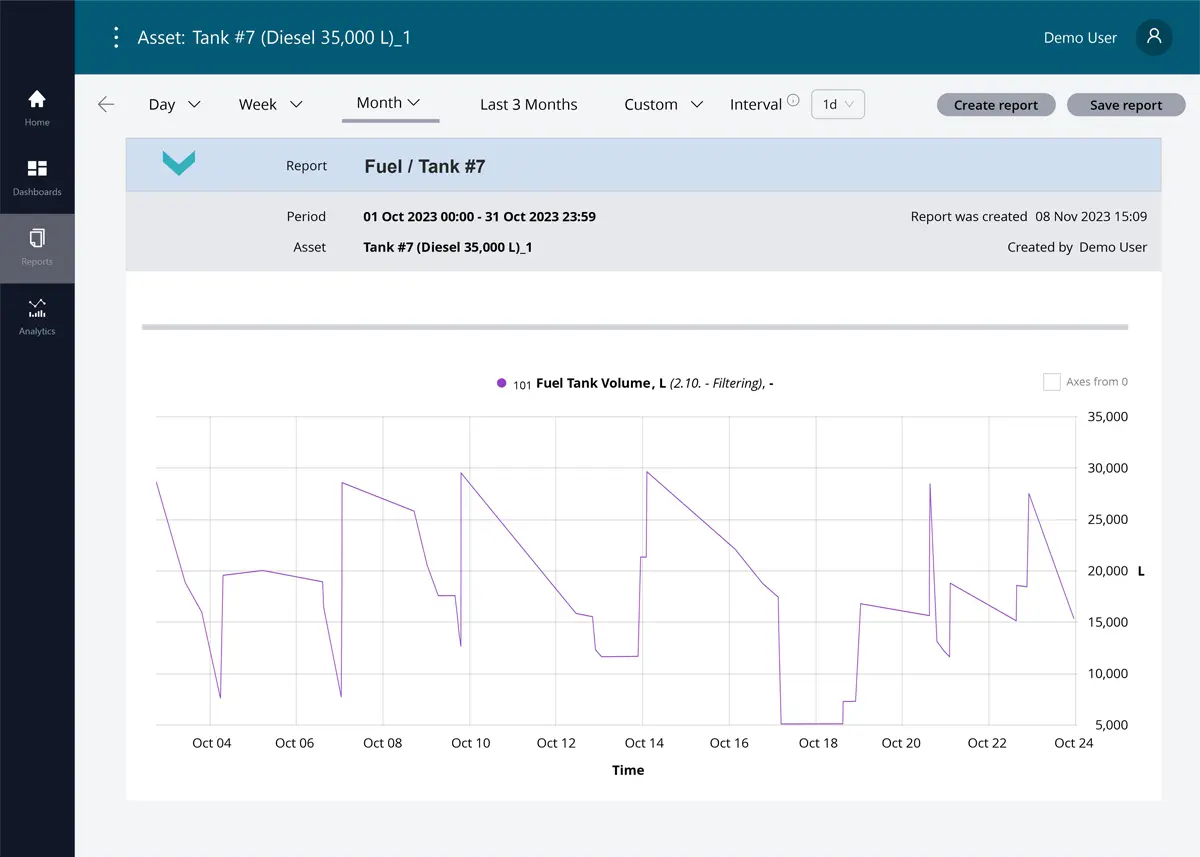

The fuel storage monitoring system tracks various parameters and sends the data over the Internet to an easy-to-use web service and mobile app. Operators, engineers, accountants, and managers at enterprises with stationary tanks receive prompt notifications through SMS and email. They also get access to reports, graphs, and a customizable dashboard for observing real-time changes in key metrics at a single location or across multiple sites.

Monitored parameters and detected events

Technoton remote monitoring system for fuel storage provides users with access to dozens of parameters in real time:

- Fuel level in millimeters

- Fuel volume in liters, % of full

- Fuel temperature

- Type of fuel in a tank

- Tank filling volumes

- Number and dates/times of fill-ups

- Total volume of dispensed fuel

- Volumes of individual portions

- Number and dates/times of dispensations

- Fuel dispensing rate (hourly consumption)

- Volume of drained fuel

- Number and timing of drainings

- Volume of cheating fuel dispensations

- Duration of cheating dispensations

- Duration of interference with flow meter operation

- Condition of fuel pumps

- Pump (flow meter) operation time

- … and over 20 other parameters.

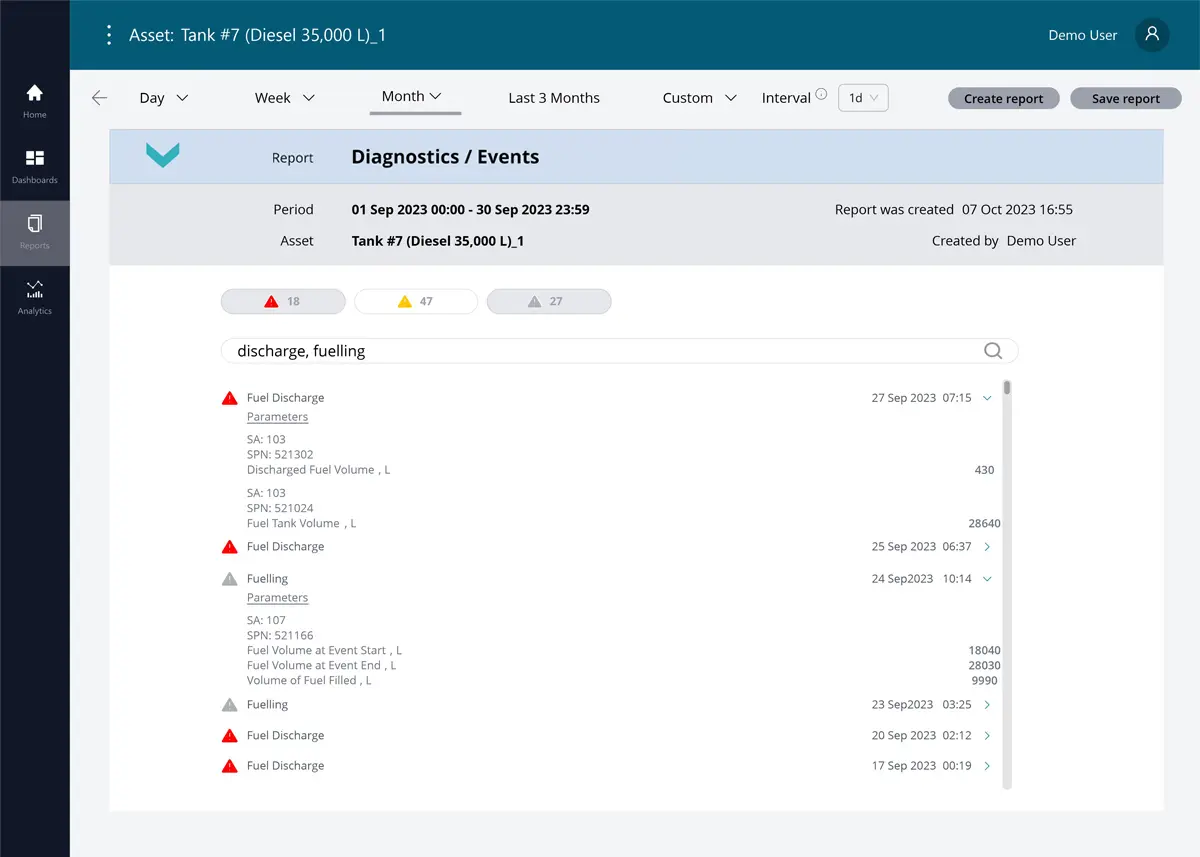

The monitoring system for stationary tanks and cisterns automatically detects key events and alerts users through an online service, email, and SMS (with message delivery even when there’s no internet connection):

- Refueling event: date & time of refueling, initial and final level of fuel, volume of replenishing.

- Fuel draining from tank: showing initial and final fuel volumes, the drained volume, and timing of event.

- Change in fuel composition: detection of foreign impurities added to the fuel.

- Fuel dispensing event: total dispensed volume, flow rate during dispensing, date & time of the event.

- Emergency remaining fuel volume: alerts when the fuel level reaches a critically low threshold.

- Interference and tampering attempts: alerts on suspicious manipulation with fuel flow meter readings.

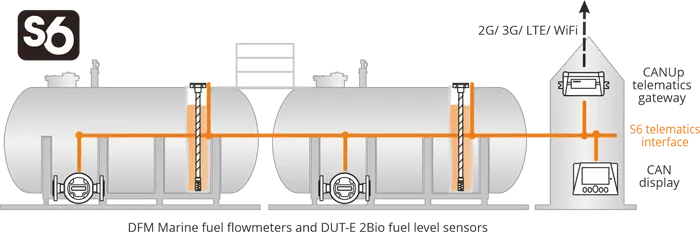

CAN J1939-based equipment for monitoring stationary tanks

using wire S6 Technology

- High accuracy with different fuel types – diesel, bio etc.

- Prompt alerts on key events – fuel theft, fill-up, fuel type change

- Data available in web-based service and on the onboard CAN display

- Centralized power supply of all sensors, set up via single connector

- Universal S6 cabling system (developed by Technoton) for easy scalability and handy addition of extra hardware.

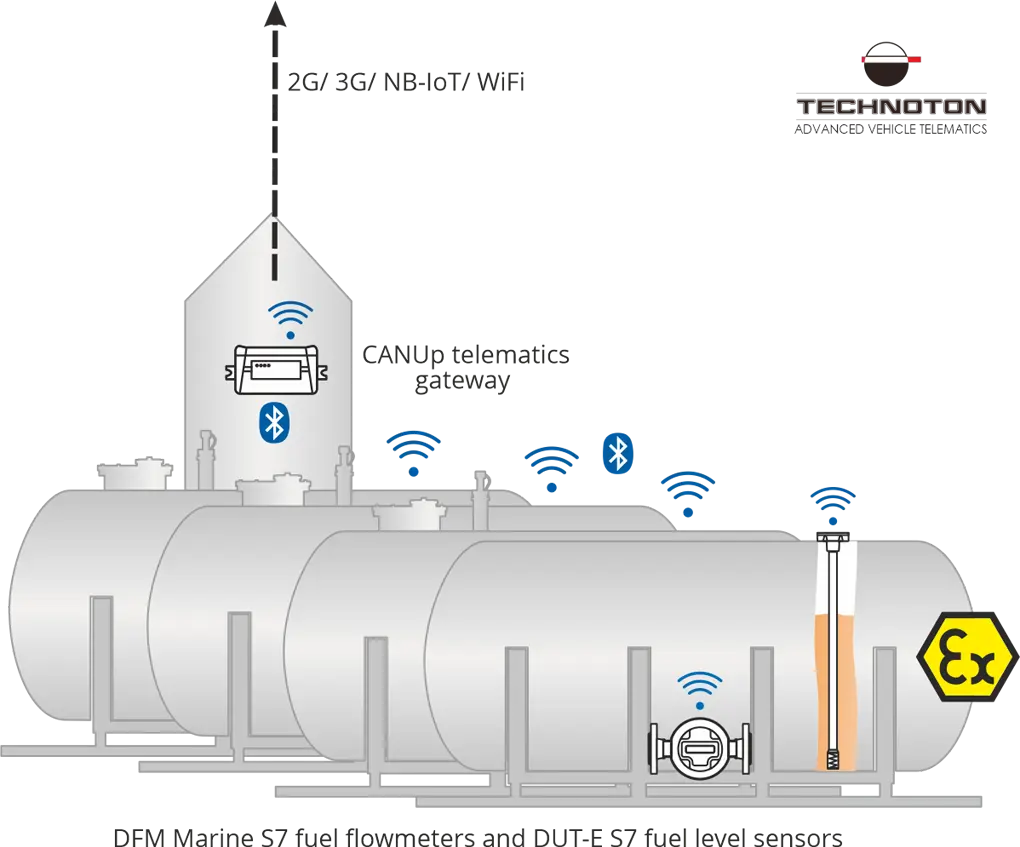

Wireless equipment for monitoring stationary tanks

using Bluetooth – S7 Technology

Data monitoring and sensor setting in mobile applications “Tank Fuel Monitor” and “Fuel Consumption Monitor”

Parameters displayed on smartphones and tablets:

- Fuel level and volume in each tank.

- Detection of “Discharges” and “Fill-up” events, showing event time and drained/filled fuel volume.

- Fuel temperature in each tank.

- Volume of dispensed fuel + resettable counter for measuring portions.

- Fuel pump operating time.

- Easy and quick installation of the sensors without cable (S7 Technology) laying.

- Increased resistance to vandalism – no cables, no risk of wire damage.

- Explosion and fire safety certified sensors (Ex-certified).

- Data transfer to multiple devices at the same time – tracker, smartphones, tablets.

- Receiving signals from 10 sensors at the same time.

Sensors, meters, gateways for remote fuel storage monitoring

Compatible telematics services and IoT platforms

Compatible telematics services and IoT platforms

Usage cases of stationary fuel tank monitoring system

Construction company

Task: bulk fuel storage tanks & fuel tanker trucks monitoring, GPS vehicle tracking.

Solution: DUT-E GSM fuel level sensor with built in GPS and GSM modules.

United Nations World Food Program (WFP)

Task: monitoring of refueling and fuel volume.

Solution: DUT-E 2Bio fuel level sensors, CANUp telematics gateway.