Online fuel volume monitoring

in stationary fuel tanks of gensets

Online fuel volume monitoring

in stationary fuel tanks of gensets

![]() Customer:

Customer:

United Nations World Food Program (WFP)

![]() Task:

Task:

monitoring of refueling and fuel volume

![]() Object:

Object:

stationary fuel tanks / fuel cisterns of diesel generators

![]() Solution:

Solution:

DUT-E 2Bio fuel level sensors, CANUp telematics gateway

![]() Result:

Result:

1) underfilling of fuel stopped,

2) uninterrupted feed of genset ensured,

3) fuel expenses decreased by 25%

Customer

The United Nations World Food Program (WFP) is the world’s largest humanitarian organization. A key area of work is providing food and medical aid to residents of countries, that are experiencing wars, natural disasters and crop failures.

Large WFP office is open in Yemen – where a civil war has been going on for several years

![]() 15 000 full-time employees

15 000 full-time employees

![]() 97 million people in 88 countries receive medical aid

97 million people in 88 countries receive medical aid

Object

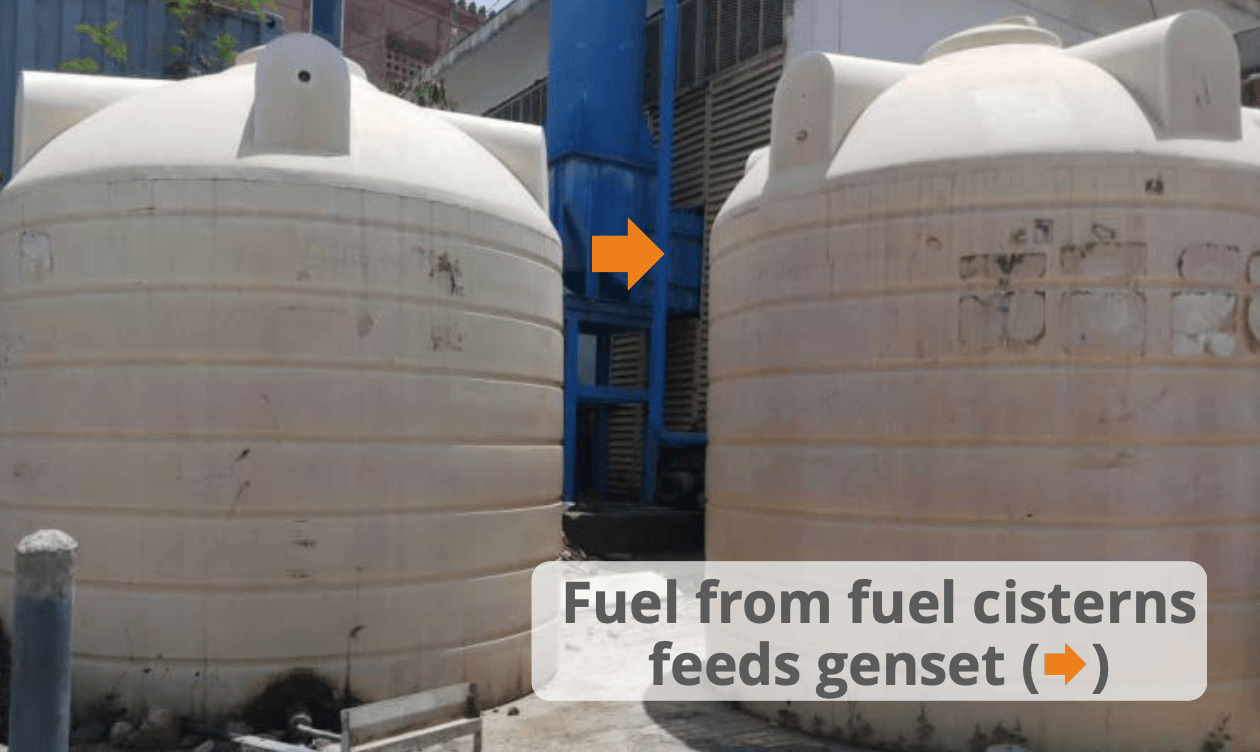

WFP offers medical care to the population in dozens of hospitals throughout Yemen. Sustainable energy supply of hospitals is provided by diesel generator sets.

Stationary cisterns of various shapes and sizes are installed to supply gensets with fuel. Height of fuel tanks is from 1000 mm to 4000 mm, volume – from 800 l to 48 000 l.

Task

WFP purchases diesel fuel for hospitals from a local provider, who brings fuel on his own and carries out fuel tank refueling. Customer receives an invoice and delivery note with data on the amount of fuel filled up. But the staff of customer’s office cannot verify in any way how accurate this data is.

For several months, electrical supply for a hospital was regularly endangered. The customer was starting to get suspicious that fuel provider is supplying less fuel than specified in documents.

An uninterrupted electricity supply is critically important for operation of hospitals. A total power outage even for a few minutes could lead to grave consequences – surgical operations will be interrupted, life support equipment, connected to emergency patients, will turn off.

WFP office faced necessity of implementing online monitoring of fuel refilling volume in each stationary fuel tank, as well as monitoring of total fuel volume in several cisterns, that provide gensets with power.

Solution

To solve the problem of fuel monitoring, customer turned to telematics system provider. The provider company offered Technoton’s fuel monitoring system based on DUT-E 2Bio differential fuel level sensors and CANUp telematics gateways.

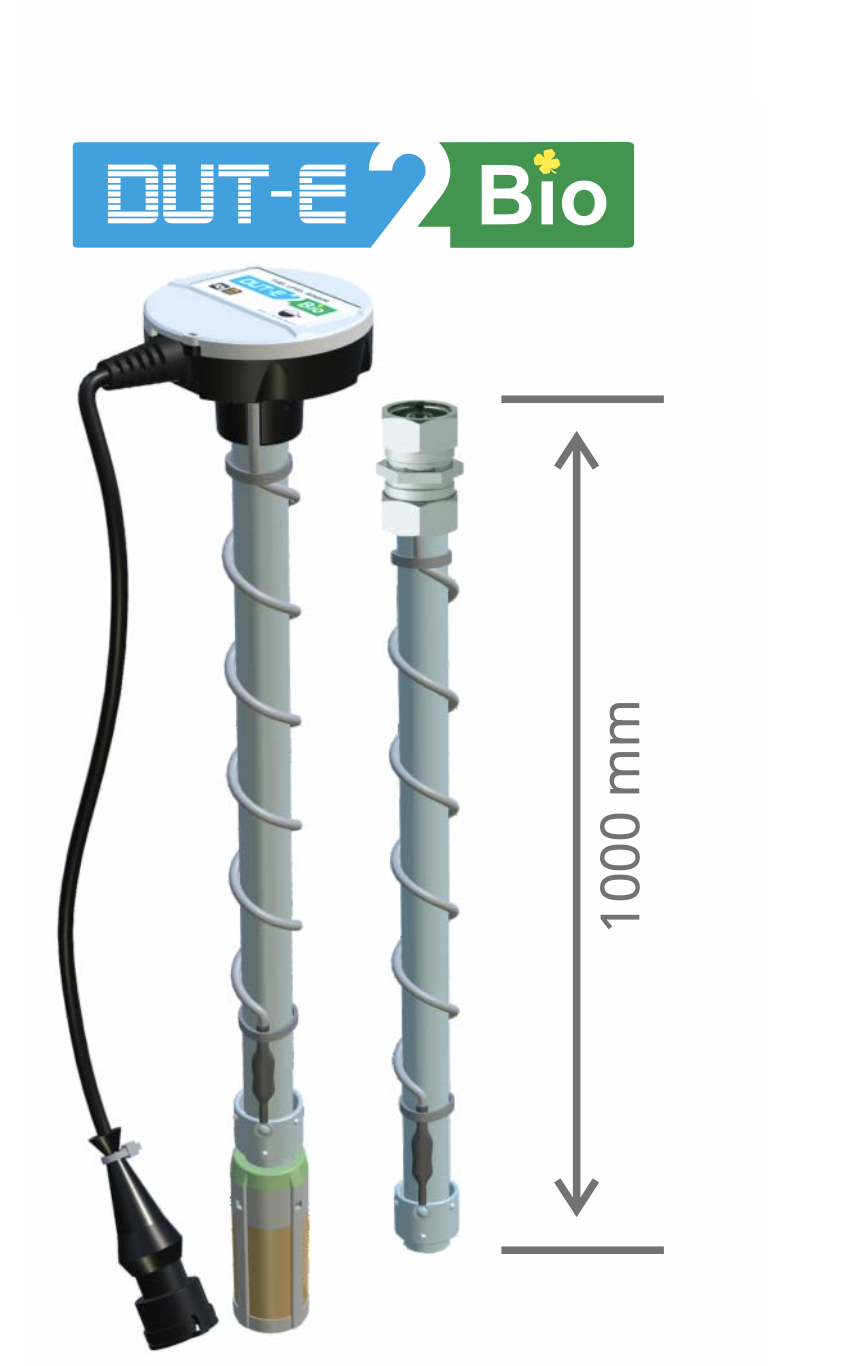

Quality of supplied fuel is unstable: permittivity value changes depending on delivery. DUT-E 2Bio fuel sensor measures real fuel volume in cisterns/stationary fuel tanks with high accuracy. The third electrode, placed at the bottom of fuel tank, identifies change in permittivity of fuel. When a new portion of fuel of any volume is added to fuel tank/cistern, fuel sensor automatically corrects result of measurement. However, measurement inaccuracy not more than ± 1%.

To reduce transportation costs, sensors are supplied with a length of 1000 mm and with additional sections of 500 or 1000 mm. During mounting, installer extends measuring part of sensor to required length in a few minutes.

The number of cisterns, that supply genset with fuel, is from three to six. DUT-E 2Bio sensors with CAN j1939/S6 interface and S6 Technology are installed on them. All sensors and CANUp telematics gateway are combined into a single network with a common power supply.

Differential fuel level sensor and additional section

Provider’s project manager

“DUT-E 2Bio differential fuel level sensors were chosen as the best tools for solving task of our customer. At first, sensors measure fuel level with high accuracy and allow remotely monitoring of fuel quality. In case, a new delivery of fuel differs in permittivity value from the previous one, customer receives online notification. Secondly, devices are easy to mount – they can be extended with additional sections to required length. Thirdly, S6 Technology allows quick connecting to a single network and configuration of sensors and CANUp telematics gateway. All necessary information is transmitted to ORF4 telematics service.”

Result

Customer receives data on fuel volume in each stationary fuel tank in real-time. Accuracy of fuel volume measurement does not depend on fuel quality/temperature.

Even when adding a small amount of fuel, DUT-E 2Bio detects change in fuel level with a pitch of 0.1mm.

After telematics system installation, customer can monitor real volume of fuel filled up and verify it with data specified in waybill.

Underfilling of fuel by provider have been stopped, thus, fuel expenses for genset decreased by 25%. Uninterrupted feed of diesel generator set was ensured.

Ali Haqlan, WFP engineer

“At the first stage of the project, 149 items of DUT-E 2Bio differential sensors were installed. Now sensors provide reliable information on fuel volume in each cistern. Once installed, the risk of power outages in hospitals is reduced to zero. Within next months, another 606 sensors are going to be mounted. Ultimately, telematics by Technoton will be installed on 755 stationary fuel tanks, which provide 193 diesel generators with fuel.”

*Data is hidden from public access. Details on the project can be disclosed upon signing NDA