Goals and objectives

Goals and objectives

Route and location tracking

Engine diagnostics

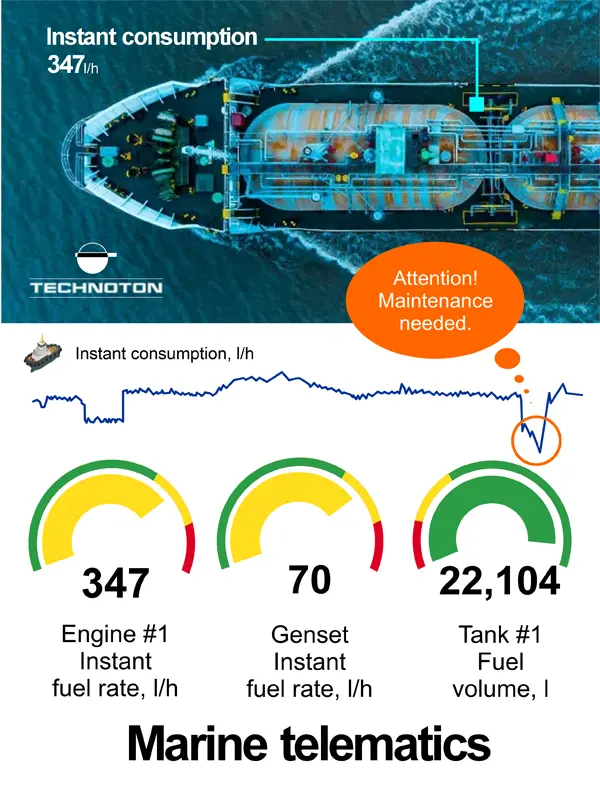

Fuel consumption monitoring and GPS location tracking of sea or river vessels (ships, boats, dredges, fishing trawlers, etc.) allows shipowners and ship operators to reduce operation costs by minimizing idling time of fleet, preventing fuel theft and improving crew discipline.

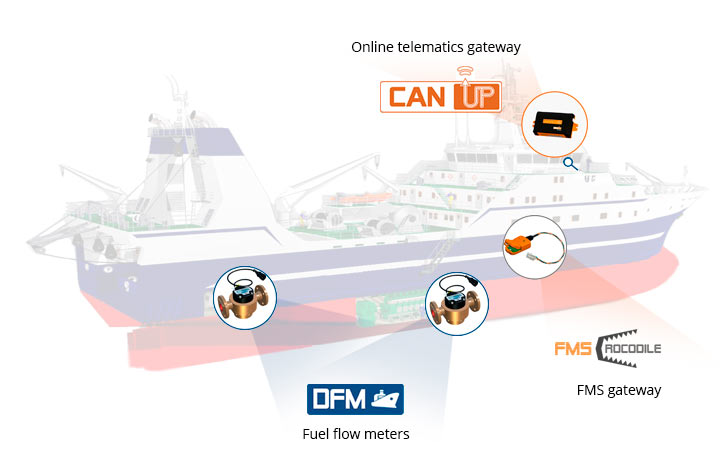

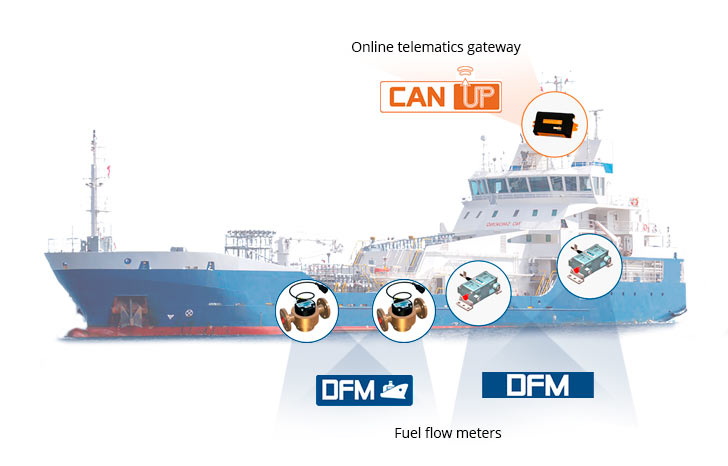

Technoton’s telematics system for sea and river watercrafts is based on accurate tools for fuel consumption measurement – DFM and DFM Marine fuel flow meters that are mounted in fuel line of main engine, auxiliary engines, diesel generators and boilers/heaters. It can also include DUT-E fuel level sensors, which are installed in fuel tanks, and MasterCAN DAC i/o modules for gathering signals from standard analog sensors of a ship/boat. The equipment supports NMEA 2000 (but also MasterCAN S7 NMEA data converter can be used for integration fuel consumption data from DFM S7 and DFM Marine S7 wireless flow meters into the NMEA 2000 ship bus), CAN J1939/S6 as well as other digital and pulse protocols.

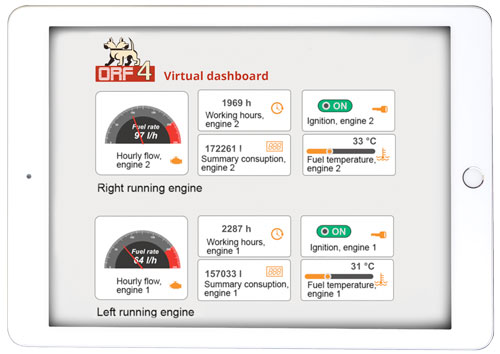

Marine telematics system provides precise information on vessel’s position, real fuel consumption, engine operation hours in different work modes (idle, optimal, overload), possible fuel draining from tank and other necessary operation parameters. Information is gathered and analyzed by CANUp telematics gateway and sent to the web-based ORF4 telematics service, where it can be displayed on virtual dashboard and as tables and charts.

Based on data from DFM flow meters on fuel consumption by engine modes, it is possible to calculate the amount of carbon dioxide (CO2) emissions into the atmosphere, as well as find ways to reduce the carbon footprint of watercraft vessels: limiting idle time, consumption based engine diagnostics, selection of the optimal speed, switching to biodiesel.

Monitored parameters

- fuel level in tank

- hourly fuel consumption

- total fuel consumption, L

- fuel temperature

- total fuel consumption in “Idling”, “Optimal” and “Overload” mode of engine operation

- total fuel consumption in “Negative” mode of flow meter operation (return exceeds supply)

- Moment hours (operating time)

- total operating time in “Idling”, “Optimal” and “Overload” engine operation mode

- coolant temperature

- engine oil pressure

- current engine operation mode as per fuel consumption rate

- operating time of Supply and Return chambers in each mode of engine operation

- Events «on/off power supply», “Tampering”, “Interference” modes

- engine operating time in “Tampering”, “Interference” mode, h

- current engine operation mode as per fuel consumption rate

- vessel location

- data from standard and additional analog sensors (via digital-to-analog converter MasterCAN DAC2113)

Technical options

Using contactless reader FMSCrocodile you can speed up the installation process by simply connecting it to the wires. DFM Marine is good for measuring actual fuel consumption in line at a flow rate of up to 4 m3 / h of primary and secondary generators.

This solution ensures:

- Informing by SMS or email about important events occurring with vessel, for example, fuel drain, sensor wrapping, minimum balance, etc .;

- Control of actual fuel consumption;

- Monitoring of important operating parameters, oil pressure, engine temperature, etc. more than 100 parameters;

- Monitoring of the engine operating time in total and on “idle”, “optimal”, “overload” operating modes;

- Location control by GPS.

Complex solution provides with real-time data about actual fuel consumption, engine operation modes, as well as diesel generators and boilers.

This solution ensures:

- Informing by SMS or email about important events occurring with vessel, for example, fuel drain, sensor wrapping, minimum balance, etc.;

- Monitoring of actual fuel consumption of main and standby generators;

- Monitoring of actual fuel consumption with a large fuel consumption (from 0.02 to 4 m3 / h);

- Monitoring of the engine operating time in total and on “idle”, “optimal”, “overload” operating modes;

- Location control by GPS.

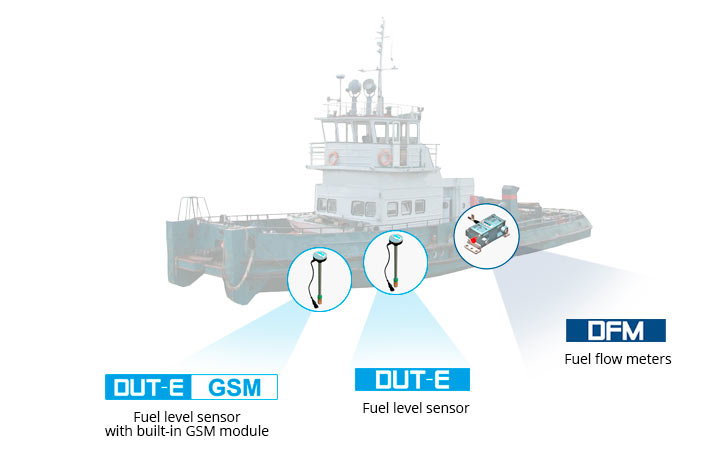

Marine telematics system based on using DUT-E, DUT-E GSM and DFM flowmeter is suitable for vessel location monitoring, as well as for real-time monitoring of the main parameters: fuel level in main and secondary tanks, actual fuel consumption and engine operating time in different modes and other.

This solution ensures:

- Informing by SMS or email about important events occurring with the vessel, for example, fuel drain, sensor tampering, minimum balance, etc .;

- Remote diagnostics and sensor configuration via SMS commands;

- Control of fuel level in the tank;

- Location control by GPS;

- Control of actual fuel consumption;

- Monitoring of engine operating time in total and by operation modes: “Idle”, “Optimal”, “Overload”.

Technical options

Using contactless reader FMSCrocodile you can speed up the installation process by simply connecting it to the wires. DFM Marine is good for measuring actual fuel consumption in line at a flow rate of up to 4 m3 / h of primary and secondary generators.

This solution ensures:

- Informing by SMS or email about important events occurring with vessel, for example, fuel drain, sensor wrapping, minimum balance, etc .;

- Control of actual fuel consumption;

- Monitoring of important operating parameters, oil pressure, engine temperature, etc. more than 100 parameters;

- Monitoring of the engine operating time in total and on “idle”, “optimal”, “overload” operating modes;

- Location control by GPS.

Complex solution provides with real-time data about actual fuel consumption, engine operation modes, as well as diesel generators and boilers.

This solution ensures:

- Informing by SMS or email about important events occurring with vessel, for example, fuel drain, sensor wrapping, minimum balance, etc.;

- Monitoring of actual fuel consumption of main and standby generators;

- Monitoring of actual fuel consumption with a large fuel consumption (from 0.02 to 4 m3 / h);

- Monitoring of the engine operating time in total and on “idle”, “optimal”, “overload” operating modes;

- Location control by GPS.

Marine telematics system based on using DUT-E, DUT-E GSM and DFM flowmeter is suitable for vessel location monitoring, as well as for real-time monitoring of the main parameters: fuel level in main and secondary tanks, actual fuel consumption and engine operating time in different modes and other.

This solution ensures:

- Informing by SMS or email about important events occurring with the vessel , for example, fuel drain, sensor wrapping, minimum balance, etc .;

- Remote diagnostics and sensor configuration via SMS commands;

- Control of fuel level in the tank;

- Location control by GPS;

- Control of actual fuel consumption;

- Monitoring of engine operating time in total and by operation modes: “Idle”, “Optimal”, “Overload”.

Features

![]() Route, course and speed monitoring

Route, course and speed monitoring

![]() Monitoring of hourly and total fuel consumption of each engine consuming fuel

Monitoring of hourly and total fuel consumption of each engine consuming fuel

![]() Distinguishing fuel consumption in different work modes – idle, optimal, overload

Distinguishing fuel consumption in different work modes – idle, optimal, overload

![]() Notification on important events in real time via ORF4 telematics service, by e-mail or SMS

Notification on important events in real time via ORF4 telematics service, by e-mail or SMS

![]() Post-trip analysis: distance, idle time, fuel consumption per trip, compliance with schedule, etc.

Post-trip analysis: distance, idle time, fuel consumption per trip, compliance with schedule, etc.

Usage cases

Ventspils port, Latvia

Task: monitoring of fuel consumption and prevention of manipulations with fuel.

Solution: DFM 250 AK fuel flow meters for gensets and DFM 250 DK for engines.

Transportation company

Task: fuel consumption monitoring of river vessels and optimization of routes.

Solution: DFM 250CCAN fuel flow meters, DFM 100CCAN fuel flow meters, GPS-trackers.

Large logistics companies

Task: fuel consumption monitoring of sea vessels, composition of efficient fleet monitoring system for multimodal transportation.

Solution: DFM Marine, DFM 250CCAN and DFM 100CCAN fuel flow meters. Data can be sent to telematics service and dashboard.

Result: operation costs reduction up to 40%