Engine run time and performance monitoring

Engine run time and performance monitoring is one of fleet management tasks, which allows analyzing workload of vehicles, increasing fleet productivity, optimizing maintenance schedule and costs and extending engine lifetime. Solution of that task also makes reporting and accounting of special equipment operation more transparent and understandable.

Vehicle telematics and GPS tracking systems can automate monitoring of run time and operating modes of equipment. This provides fleet manager with solid ground for eliminating overstated operation hours and fuel consumption, reduce maintenance and repair costs, and link amount of completed work with hours spent and fuel used.

The classic method of tracking engine run time – using standard engine hour meter of vehicle. Disadvantage of this method, and therefore accounting of fuel used based on engine hours, is the lack of information on actual engine workload intervals, idling time and full load operation.

No time for reading?

Where engine run time and performance monitoring is used

Engine run time and performance monitoring is applicable for mobile and stationary equipment (machinery), including road trucks and small commercial vehicles. However, run time and work load monitoring is most useful for fleets of advanced machinery.

Advanced machinery (also called complex vehicles or special equipment) has powerful internal combustion engines, sometimes even two or three engines at the same time, working for a long time or non-stop. The engine load of such machinery is mostly uneven – meaning operation conditions of machinery make engines switching between idling, optimal and overload modes.

Maintenance and repair costs account for up to 50% of fleet budget. Hence, a small relative increase in the efficiency of special equipment leads to a noticeable absolute costs reduction and time spent on fleet management.

How to implement engine run time and performance monitoring

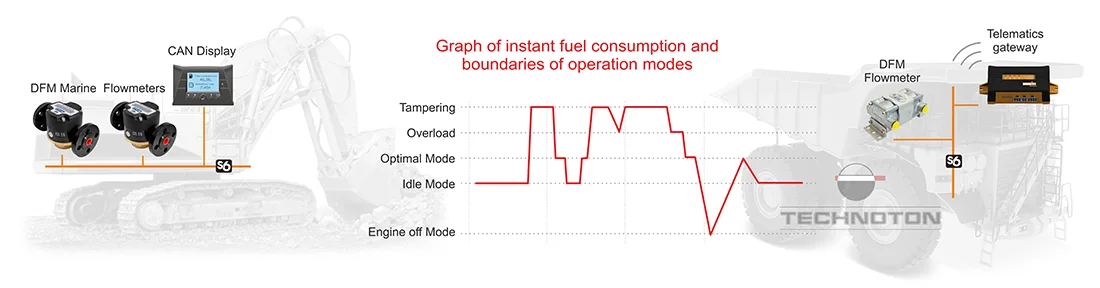

1. Direct method using fuel rate measurement

DFM fuel flow meters are installed in the fuel line. The flow meters measure real engine fuel consumption and operating time of the engine using fuel rate. This includes fuel monitoring separately in supply and return lines, thus helping to detect engine load:

- “idling”,

- “optimal”, i.e. normal flow range for a given piece of equipment,

- “overload”, i.e. flow over the normal range.

Flagship models of DFM fuel flow meters have CAN j1939/S6 interface, which provides over 40 parameters on fuel consumption and engine working time. The information is stored in internal memory of the flow meter and transmitted to a telematics unit or GPS-tracker. The data is subsequently sent to a telematics service or other web-based server for fleet management. DFM flow meters are compatible with other fuel monitoring equipment (e.g. fuel level sensors) and can be used within a single telematics system for advanced machinery.

![]() Advantages

Advantages

- Direct fuel measurement principle, uses instant flow rate

- Detects different engine load modes

- Applicable for equipment with one, two and more engines

- DFM flow meters are protected against tampering and interference

- Can be integrated to existing telematics system of a fleet

![]() Disadvantages

Disadvantages

- Requires time and skill of installer

2. Indirect way using CAN bus data

Total engine working hours are determined by data from CANbus – ignition on / off and engine speed are used. Figuring out engine work load requires the use of formulas or manual analysis of the information received.

Safe connection to CAN J1939 or J1708 bus is carried out using contactless readers CANCrocodile, 1708Crocodile or FMSCrocodile. Direct connection to the wires (twisting, soldering) is not a safe way and can lead to ECU errors.

![]() Advantages

Advantages

- Quick installation of Crocodile contactless reader

- Allows obtaining additional parameters of engine operation

![]() Disadvantages

Disadvantages

- Data analysis requires many efforts and time, or not possible at all

- Some tracking units do not have required input, J1939 data converter is needed

- Required CAN bus data is missing or encrypted/hidden by vehicle manufacturer

Benefits of implementing engine run time and performance monitoring

Reduce machinery idling time

Analysis of duration and reasons of equipment idling allows fleet manager to increase productivity of work performed, reduce fuel consumption, and optimize technical maintenance schedule.

Prevent fuel theft

Monitoring the actual operating time of the equipment leaves no room for overstating fuel consumption and draining “excess” fuel.

String drivers’ salary to work performed

Accurate engine run time control, considering engine load modes, makes it possible to pay for the work of machinery operators according to actual hours worked.

Increase quality of work performed by machinery

Monitoring engine workload makes impossible presenting idling as real work. For example, it helps to reveal “tricks” with raising a brush of a winter service vehicle or insufficient deepening of a tractor’s plow.

Extend machinery lifetime

Engine workload control helps to reduce careless equipment operation. For example, at high RPM with excessive fuel consumption, and as a result, increased engine wear.

Eliminate unnecessary expensive repairs

Engine run time and performance monitoring allows switching to technical maintenance according to machinery workload. That reduces risks of breakdowns and costly repairs of equipment – predictive maintenance.