Fuel monitoring of diesel generators

combined with solar panels

Fuel monitoring of diesel generators

combined with solar panels

![]() Customer:

Customer:

The Hevel Group (Russia)

![]() Task:

Task:

fuel consumption monitoring of diesel-solar systems

![]() Machinery:

Machinery:

power generators (diesel)

![]() Solution:

Solution:

DFM fuel flow meters

![]() Result:

Result:

measuring exact fuel consumption, aligning billing system with energy resources used

The Customer

The Hevel Group was founded in 2009 and it’s Russia’s largest integrated solar energy company. The Hevel Group produces solar modules, builds and operates solar power plants and also makes research in the field of solar energy.

Hevel offers a full range of services, from production of solar modules, to design, construction and operation of photovoltaic systems. Company can develop and carry out turn-key construction of solar system of any capacity and type (autonomous or connected to power system).

![]() 500+ employees

500+ employees

![]() 364+ MW total capacity of solar power

364+ MW total capacity of solar power

The Machinery

The autonomous hybrid plant is mounted in Menz village (Transbaikalia territory, Russian Federation). It supplies electrical power to three inaccessible settlements seamlessly.

Plant consists of solar modules (1) with total capacity of 120 kW, two diesel generators (2) of 200 kW each and energy storage (accumulators) (3) with capacity of 300 kW*h. Inverters (4) distribute load between solar cells, diesel generators and accumulators. They also provide batteries charging.

Monitoring system for fuel economy of diesel generators

Volvo Pentа TAD734GE

The Task

Diesel generators are equipped with Volvo Pentа TAD734GE engines with power of 363 h.p. Engine is six-cylinder, working volume – 7,15 L, with in-line arrangement of cylinders and injection system with electronic control of Common rail injectors.

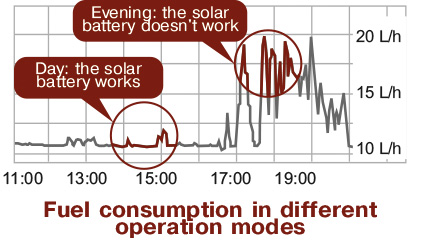

Fuel consumption depends on electric load of engine (from 16 L per hour at load of 25 % to 54 L per hour at full load).

The customer mounted hybrid plant on request of state operator of power networks. The customer’s income is determined by energy servicing agreement – the higher fuel economy, the more operator of power networks pays.

Monitoring system, that accurately measures fuel consumption and sends data to the customer in real time, is needed to find out volume of consumed fuel and fuel economy.

The Solution

Fuel consumption monitoring system of autonomous hybrid plants is based on DFM differential fuel flow meter and online telematics unit.

DFM Differential fuel flow meter is mounted into fuel system and measures actual fuel consumption. Its installation doesn’t influence fuel flow in the system. The flow meter records operation time of engine in various operation modes and also registers interferences into system.

Data from the flow meter (instant and total fuel consumption, engine operation time and fuel consumption in idle, optimal and overload modes, fuel temperature) is sent to online telematics unit via RS-485 digital interface. Information from telematics unit is send to dispatch service computer in real time. Data on fuel consumption and engine operation time is available in reports and diagrams.

Victor Panasuk, Technoton

“Technoton produces a wide range of DFM fuel flow meters for all kinds of vehicles. DFM 250D differential fuel flow meter is optimal solution for Volvo Pentа TAD734GE engine. Its installation takes minimum time and there is no need to modify fuel supply system, because flow meter has two chambers - for fuel supply and fuel returns lines.”

The Result

Taking in account operation experience, the customer is convinced that monitoring system (fuel flow meter and online telematics unit) provides reliable information on fuel consumption and operation time of engine. Financial results of the contract and payments to the customer are evaluated with the help of this information.

The autonomous hybrid plant in Menz village is the first one mounted within the scope of National energy project “Creation of local and integrated in IEA energy supply sources based on new generation photovoltaic heterostructural modules”. In total, more than 100 autonomous hybrid power plants will be built until 2021.

All autonomous hybrid power plants will be built and operated under the agreement with state operator of power networks. The Hevel Group plans to mount fuel consumption monitoring systems on all plants within the National project.

Dmitri Saveliev,

The Hevel Group

“We decided to mount DFM fuel flow meters designed by Technoton on all our power plants. This was the right decision. DFM performed well on our equipment (diesel generators’ engines). Flow meters work accurately and without failures.

We plan to continue installation of DFM fuel flow meters on autonomous hybrid power plants.”