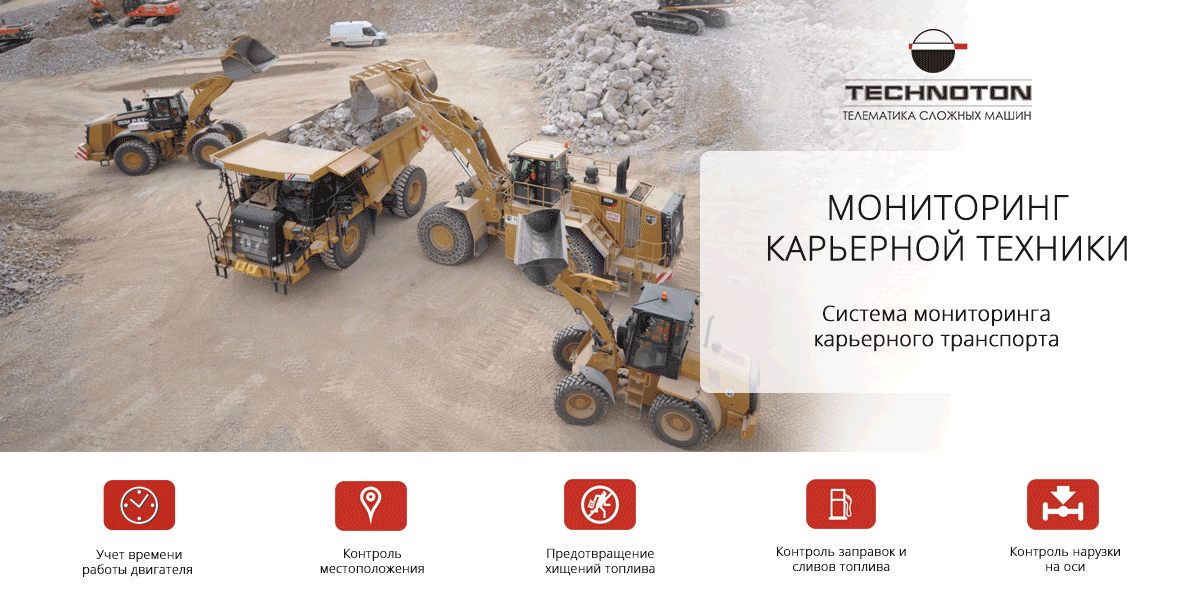

Mining equipment monitoring

Mining equipment monitoring

Tasks

Tasks

Monitoring of fuel consumption and operation modes of mining and quarrying equipment (rock trucks, bulldozers, crawler tractors, loaders, power units) allows to reduce operation costs, prevent fuel theft and equipment breakdown.

The main feature of Technoton’s solutions for quarry equipment is using DFM Marine fuel flow meters, which were designed for equipment with fuel consumption up to 4000 L/h. Also solution can include DUT-E fuel level sensors, which are installed in fuel tanks and determine accurate fuel level. The solution can be extended with axle load and/or bucket position monitoring by adding GNOM axle load/shift sensor. All received data is proceed by CANUp telematics gateway and sent to the web-based ORF4 telematics service, or directly by SMS, e-mail or messenger.

Reports, parameters, notifications

Fuel consumption control

- Hourly fuel consumption in “Forward”/“Return” line

- Total fuel consumption, L

- Total fuel consumption in “Idling”/“Optimal”/“Overload” mode of engine operation

- Total fuel consumption in “Negative” mode of flow meter operation (return exceeds supply)

Data for reports

- Operating time of ICE (engine hours);

- Mileage;

- Fuel consumption per shift;

- Cargo weight.

Operating parameters monitoring

- Fuel temperature;

- Temperature correction status;

- Correction coefficient value;

- Battery charge.

Informing about intervention

- Engine operating time in “Tampering” mode, h

- Engine operating time in “Interference” mode, h

Technical options

Usage cases

Thiess, mining services provider, Australia

Task: fuel volume monitoring for planning machinery operation.

Solution: DUT-E fuel level sensor + tracking device.

Quarry for gypsum mining, USA

Task: accounting of fuel consumption per ton of product.

Solution: DFM Marine fuel flow meters, telematics control unit and software.

Want tailored monitoring solution for your mining equipment or have some question?

Fill in the questionnaire and we will contact you soon.