Tasks

Real-time data monitoring

Remote management

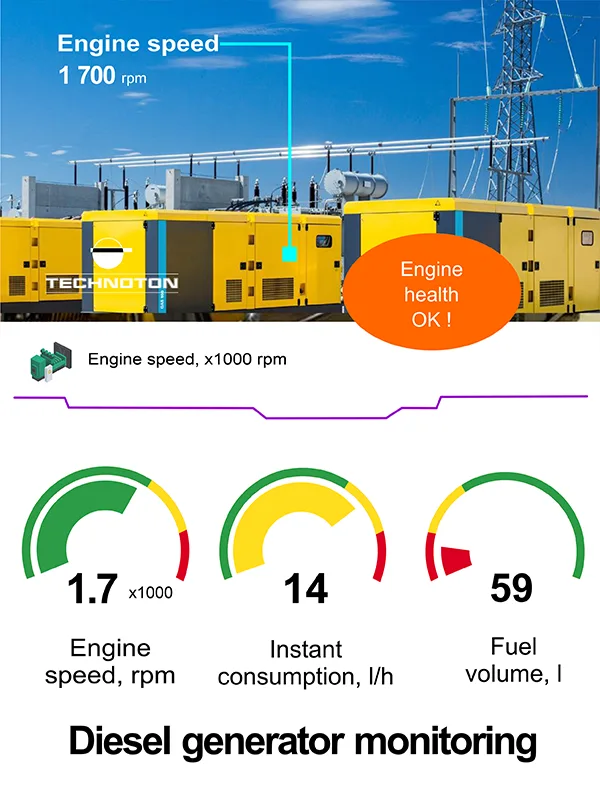

Diesel generator monitoring is a hardware and software solution for fuel monitoring, monitoring of diesel generator operation parameters and engine diagnostics, receiving electrical data from alternator and remote genset control.

Smart solution for remote monitoring of diesel gensets allows ensuring uninterrupted operation of DG, reducing fuel and operation costs, optimizing maintenance schedule and preventing generator service outage, thus extending genset life cycle.

Diesel generator monitoring

Smart solution for remote monitoring

of diesel gensets

Tasks

Diesel generator monitoring is a hardware and software solution for fuel monitoring, monitoring of diesel generator operation parameters and engine diagnostics, receiving electrical data from alternator and remote genset control.

Smart solution for remote monitoring of diesel gensets allows ensuring uninterrupted operation of DG, reducing fuel and operation costs, optimizing maintenance schedule and preventing generator service outage, thus extending genset life cycle.

Diesel generator monitoring field of application

Remote diesel generator monitoring (also called generator telematics) is used for industrial and residential power generators, which are used as main, reserve or auxiliary energy source.

Users of the system:

- Owners and operators of generators. Remote supervision of operation and diesel generator management, genset fuel monitoring, getting data for accounting and predictive maintenance.

- Servicing companies, engaged in DG maintenance and repairs. Diagnostics of engine and alternator, operating time monitoring, maintenance scheduling, just-in-time servicing and replacement of consumables.

- Diesel generator manufacturers. Remote monitoring of genset operation, engine and alternator health monitoring and overall genset diagnostics, gathering failure statistics, planning adjustments to genset design.

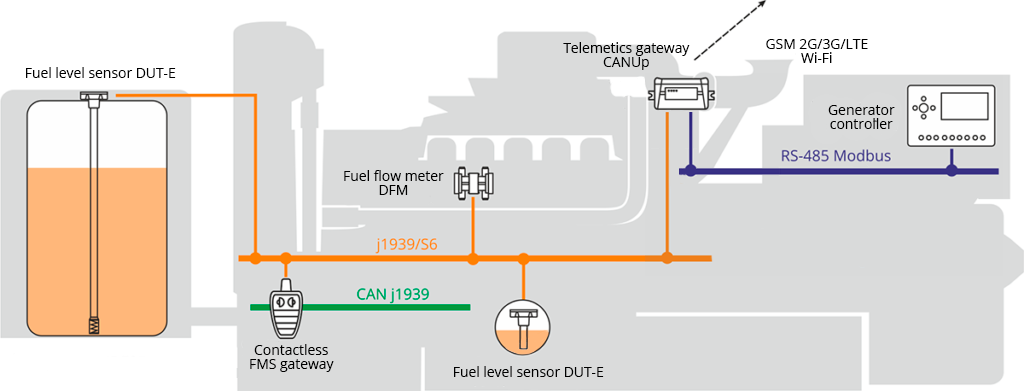

Hardware for diesel generator monitoring

Main operating parameters are measured by additional and standard diesel generator sensors – fuel level, fuel flow and others, also received from Modbus RTU data converter.

Genset monitoring system includes the following measurement equipment (additional gensets sensors):

- fuel level sensors,

- fuel flow meters,

- I/o modules,

- Modbus RTU converters of data from a genset controller,

- CAN bus readers from engine J1939 data bus,

- telematics gateway.

All sensors and genset controller are connected into a single network over J1939/S6 interface or over-the-air wireless S7 Technology.

Telematics gateway (also called tracking unit or telematics unit) generates reports on generator operation using received parameters and sends information over the Internet (2G, 3G, LTE) to a web-based software platform. Also, diesel generator operation parameters can be checked locally on the screen of CAN display or genset controller screen.

Remote generator monitoring online

Genset engine and alternator operation parameters are measured and sent online in real time. Web-based genset monitoring and management platform shows users current values of parameters of each generator, group of generators or the whole genset fleet.

Genset monitoring and management platform allows a user to check genset operation for the selected period, generate analytical reports – on genset fuel consumption, generated power, engine workloads and so on. The platform is available 24/7 from PCs and smartphone with connection to the Internet.

UNUM Genset is a next-level solution for 24/7 monitoring and remote control of diesel generators. It combines smart telematics devices and modern software to improve efficiency, reduce fuel costs, ensure reliable operation across mixed fleets and environmental compliance.

Genset parameters monitored

Up to 400 operating parameters of a generator. In addition to sending data online, smart solution for remote monitoring of diesel gensets sends reports via email and SMS-notifications on detected events – engine start/stop, load on/off, parameter value drop, emergency stop, fuel theft and others.

Technoton solution for diesel generator monitoring is flexibly configured depending on type and model of a genset, installed DG controller and requirements of genset owner or operator to the parameters, which should be remotely monitored.

Engine

Instant fuel consumption;

Average fuel consumption per hour;

Fuel volume in tank;

Fuel level in tank;

Engine RPM;

Coolant temperature;

Oil pressure;

Power network voltage;

Engine workload mode;

Battery voltage;

Battery mode – charging/ not charging;

Total fuel used;

Total engine operation hours;

Engine operation hours for a period;

Engine running time after the start;

Total number of engine starts;

Number of failed engine starts;

Energy production per liter of fuel.

Electric generator

Cos φ;

Generator frequency;

Generator voltage;

Generator voltage L1-N;

Generator voltage L2-N;

Generator voltage L3-N;

Generator current;

Generator current L1;

Generator current L2;

Generator current L3;

Real power;

Real power L1;

Real power L2;

Real power L3;

Reactive power;

Total apparent power;

UPS battery voltage;

UPS remaining time;

Enclosure temperature;

Status of enclosure/container cooling fan – working/not working;

Status of enclosure/container blinds – opened/closed;

Total energy produced.

Engine

Maximum fuel consumption rate exceeded;

Too high RPM;

Low oil pressure;

High oil pressure;

Engine start failed;

Cold start;

Hot stop;

No data in CAN bus;

Low fuel level in tank;

Fuel tank fill up;

Fuel tank draining;

Engine start/stop;

Too high coolant temperature ;

Too high oil temperature;

Low UPS battery voltage.

Alternator

Emergency stop button pushed;

Too high voltage;

Too low voltage;

Too high frequency;

Too low frequency;

Too high current;

Too high power output;

Low Cos φ;

Phase imbalance;

Overload;

Enclosure/container door opened;

Fire alarm.

Genset automation and control

Technoton products for generator monitoring allow automation of some processes. For example, using data from fuel level sensor for diesel generator, DUT-E SAU fuel supply automation unit sends control signal to switching relay of a fuel pump, which ensures fuel pumping from storage fuel tank to main feed tank of a diesel genset. After fuel level in the main feed tank of the generator reaches a certain pre-defined value, DUT-E SAU fuel supply automation unit will send another control signal to switch off the pump. That kind of automation ensures uninterrupted operation of a diesel generator.

Also, the J1939 i/o module can turn off genset’s engine in case of detecting emergency value of an operation parameter, which can lead to generator breakdown – e.g. low oil pressure, too high coolant temperature and similiar.

Genset automation and control

Technoton products for generator monitoring allow automation of some processes. For example, using data from fuel level sensor for diesel generator, the J1939 i/o module send control signal to switching relay of a fuel pump, which ensures fuel pumping from storage fuel tank to main feed tank of a diesel genset. After fuel level in the main feed tank of the generator reaches a certain pre-defined value, the J1939 i/o module will send another control signal to switch off the pump. That kind of automation ensures uninterrupted operation of a diesel generator.

Also, the J1939 i/o module can turn off genset’s engine in case of detecting emergency value of an operation parameter, which can lead to generator breakdown – e.g. low oil pressure, too high coolant temperature and similiar.