![]()

Fuel supply automation unit

DUT-E SAU fuel supply automation unit is a device for fuel pump control, automating supply of fuel from a reserve tank to the main tank of a diesel-powered machinery.

The main application of DUT-E SAU is the automation of fuel supply for diesel generators. Often, DUT-E SAU is used within telematics, fuel consumption monitoring and control systems for diesel gensets.

DUT-E SAU is applicable for automating fuel supply to boilers, heaters and refrigerators (HVAC-R), and IIoT applications like “smart factory” systems.

Tasks

DUT-E SAU principle of operation

DUT-E SAU unit continuously receives signal from DUT-E fuel level sensor installed in the main tank of a diesel genset.

When the fuel level in the main tank reduces to the minimum level, DUT-E SAU turns on the fuel supply pump from the reserve tank. When the maximum level is reached — DUT-E SAU turns off the pump.

Advantages of DUT-E SAU

- compatibility with DUT-E, DUT-E 2Bio and DUT-E GSM fuel level sensors,

- suitable for pumps with nominal supply voltage 12V and 24V,

- works as part of the fuel monitoring system over S6 Technology,

- setup without programming, clear configuration software,

- easy configuration of “minimum” and “maximum” fuel levels,

- delivery set includes the necessary cables and relays.

Configuring fuel supply automation unit

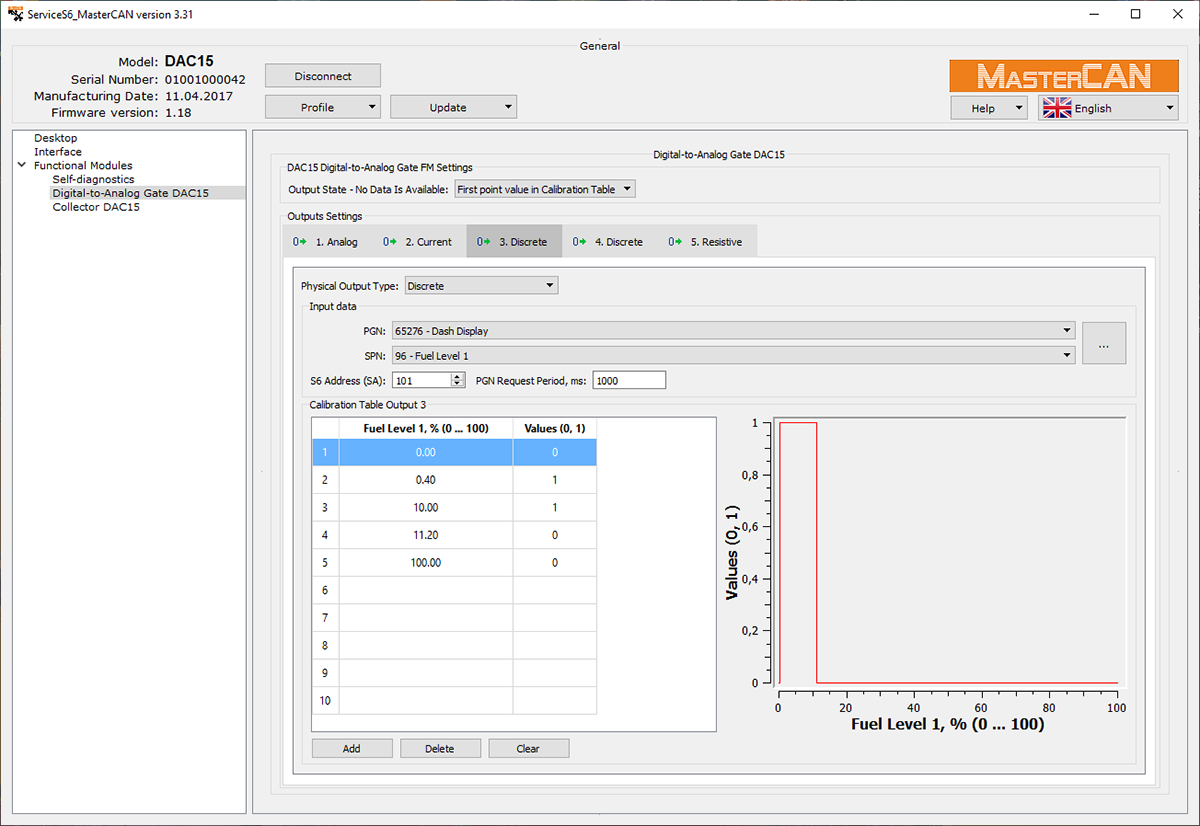

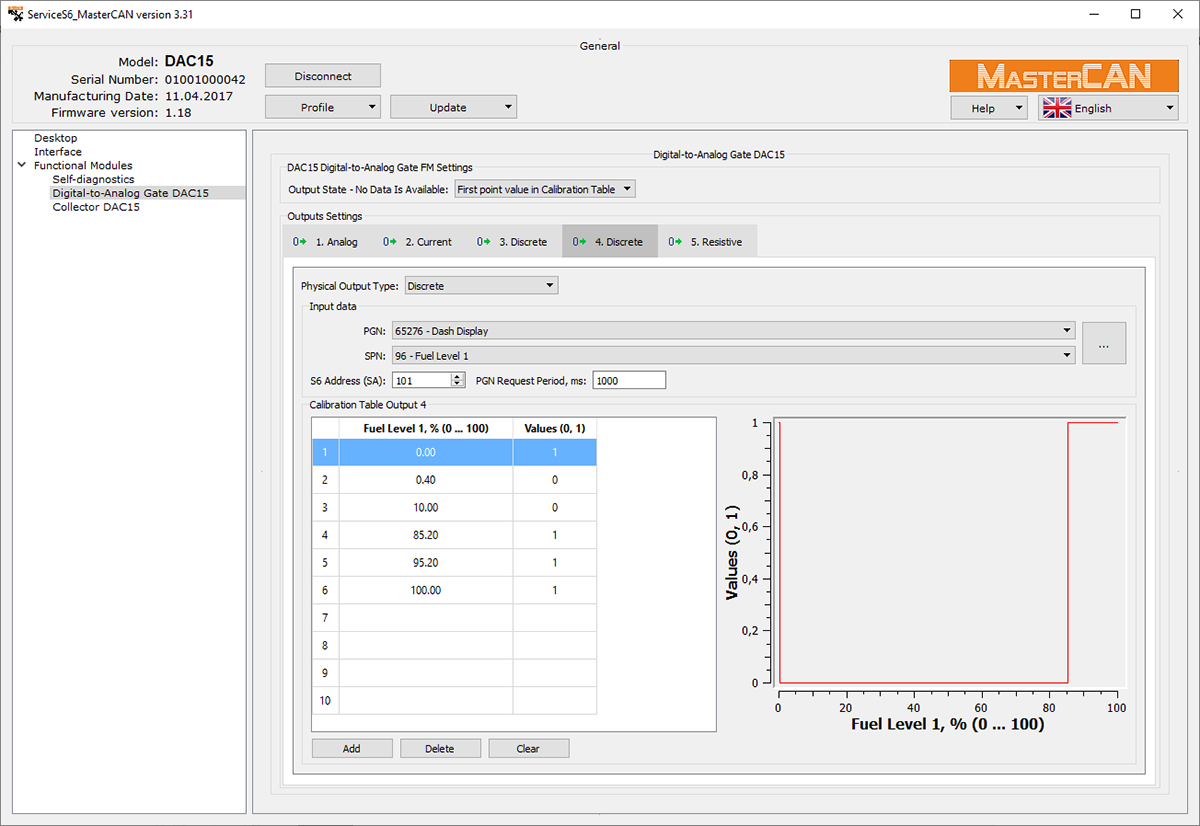

The main settings of DUT-E SAU are minimum and maximum fuel levels.

Minimum fuel level is the remaining fuel in the main fuel tank, at which the tank needs to be refueled.

Maximum fuel level is the remaining fuel in the main fuel tank, at which further refueling is not required.

Since the values of the minimum and maximum levels are indicated as a percentage of the total fuel tank volume, a preliminary calibration of the tank is necessary. Calibration data is stored in DUT-E fuel sensor’s memory. Tank calibration is the process of creating a correspondence table between the fuel level in millimeters and fuel volume in liters. Accurate tank calibration increases the accuracy of measuring the remaining fuel.

Technical specifications

| Technical specifications | SAU 12 | SAU 24 |

| Min / Max voltage, V | 9 / 16 | 20 / 29 |

| Max current consumption, A | < 0,9 | < 0,45 |

| Max switching voltage, V, В | 30 | |

| Max switching current, A | 40 | |

| Max switching power, W | 560 | |

| Operating temperature, oC | -40 ... +85 | |

| Ingress protection rating (IP code) | 66 | |

Usage cases

Monitoring fuel consumption and remaining volume in tank

Task: automate refilling of fuel tanks of generators and exclude human factor.

Solution: DUT-E 2Bio fuel level sensors, DFM D fuel flow meters.