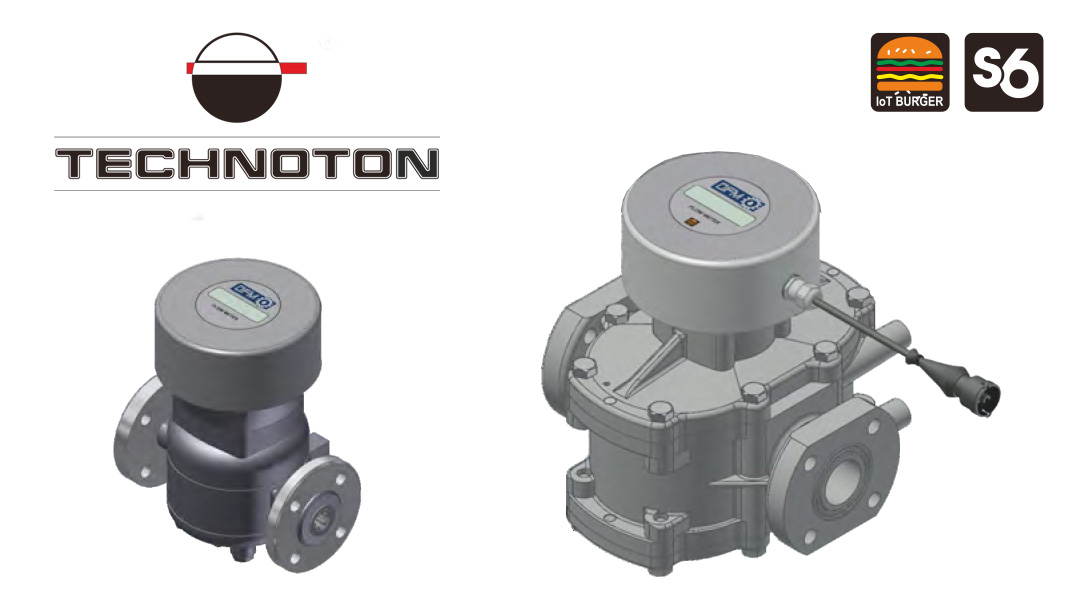

Industrial flow meter

DFM Industrial is designed for accurate flow rate measurement of fuel and other liquids used in sea and river vessels, fuel delivery from truck tankers, in high-power diesel generator sets and boilers, in petrochemical, utilities and other industrial applications (IIoT).

Model line of DFM Industrial flowmeters includes autonomous counters with electronic display only (LCD) and flow meters with LCD and output interface cable for sending data to recording devices, displays, tracking units, telematics units.

DFM Industrial flowmeter is mainly used as a part of ship monitoring and machinery operation tracking systems, and as part of Industrial Internet of Things (IIoT) systems, also as autonomous solution for fuel/ liquid consumption.

Tasks

Advantages of DFM Industrial

Embedded flow computer, built-in battery, electronic display

DFM Industrial shows measured data on electronic display: 17 Counters of fuel / liquid consumption and engine/pump operating time (see the full list). Raw data is processed by embedded flow computer, which also allows to connect 2 pieces of DFM Industrial for differential liquid consumption measurement. Built-in battery provides autonomous fuel/ liquid consumption measurement even if external power supply is switched off.

Protection against tampering

DFM Industrial records special Counters for protection against tampering attempts:

- “Interference” Counter protects DFM Industrial from magnetic field impact aimed on stopping fuel consumption measurement.

- “Tampering” Counter registers attempts of third party to tamper flow meter data by generating artificial fuel/ liquid consumption (e.g. by blowing the air through measuring chamber).

- “Number of Interventions” Counter keeps track of number of magnetic interference attempts.

Compliance with S6 Technology

DFM Industrial can be connected in one S6 network with fuel level sensors to provide detailed reporting on fuel/ liquid consumption. Operation parameters and Counters can also be transferred to S6-compatible display and recording units – e.g. MasterCAN Display 35, CANUp or GPS trackers/telematics units.

Edge/fog raw data processing using IoT Burger Technology

Edge/fog raw data processing using IoT Burger Technology

Built-in software of DFM Industrial flow meter converts raw data (inputs of physical environment) into ready-to-use information – Parameters, Counters and Events – on fuel/ liquid consumption, operation time, “Tampering”, “Interference”, “High/ low supply voltage level”, “Ignition on / off” Events.

IoT Burger Technology also allows to make advanced configurations of DFM Industrial:

- configure correction coefficient of instant flow rate;

- configure coefficient of volumetric expansion of liquid;

- carry out differential or summarization liquid flow rate monitoring in two and more pipelines within one measurement system.

Fuel/liquid consumption

- Total fuel/liquid consumption, m3

- Total fuel/liquid

- Consumption in “Idling” mode of engine operation

- Total fuel/liquid consumption in “Optimal” mode of engine operation

- Total fuel/liquid consumption in “Overload” mode of engine operation

- Total fuel/liquid consumption. Resettable

- Instant consumption

Engine operating time

- Total operating time, h

- Total operating time in “Idling” engine operation mode

- Total operating time in “Optimal” engine operation mode

- Total operating time in “Overload” engine operation mode

- Total operating time in “Negative” flow meter operation mode

Special

- Engine operating time in “Tampering” mode, h

- Engine operating time in “Interference” mode, h

- Current engine operation mode as per fuel consumption rate

- Fuel/liquid temperature

- Temperature correction status

- Correction coefficient value

- Battery charge

DFM Industrial models

The DFM Industrial product line includes the following models:

Information on display of DFM Industrial

DFM Industrial with display allows autonomous fuel consumption measurement without data transfer to a server.

Information on DFM Industrial display

Total Fuel Consumption

Total Fuel Consumption counter with higher digit capacity

Engine Operation Time

Engine Operation Time in Idle Mode

Engine Operation Time in Optimal Mode

Engine Operation Time in Overload Mode

Total fuel consumption. Resettable

Total operating time, h. Resettable

Fuel Consumption in Tampering Mode

Interference Time

Instant Fuel Consumption

Battery Charge in Percentage of the Maximum

Temperature in the Measuring Chamber

Diagnostics and configuration of DFM Industrial

DFM Industrial is configured with Service S6 DFM Industrial. It is possible to adjust the following settings of DFM Industrial:

• Boundaries of operation modes – “Idling”, “Optimal”, “Overload”, “Tampering”, “Interference;

• correction and temperature correction coefficient

• units of measurement (Metric/US)

Model

Nominal diameter DN, mm

Nominal measuring chamber volume, l

Mean time before recalibration*

DFM Industrial 25

40

1.0

60 000/10

DFM Industrial 7

25

0,1

60 000/10

Model

Starting* flow rate, m3/h

Minimum flow rate, m3/h

Maximum flow rate, m3/h

Inaccuracy** up to, %

DFM Industrial 7

0,02

0,72

7,2

±0,25

DFM Industrial 25

0,5

2,5

25

±0,25

* Minimum threshold when flow meter stars operation.

The value is indicated for reference purposes only, accuracy is not standardized in “staring-minimum” interval.

** In differential/summarization measurement mode, inaccuracy is not higher than ±1.0 %

Models

DFM Industrial 7

DFM Industrial 25

MAX flow rate

7.2 м3/h

25 м3/h

MAX pressure

1.6 / 6.4* MPa

*on request for flange connection

1.6 / 6.4* MPa

* on request

Interface

– CAN(J1939)/S6 interface

– pulse output

– autonomous (without interface)

Kinematic viscosity of liquid

0.55-300 mm2/s (cSt)

Ambient operation temperature

from -20 to +60 °С

Operating principle

oval gears rotation

Connection to pipeline

flange, thread

Battery lifetime

up to 36 months

Measurement chamber characteristic

| Nominal diameter DN, mm | |

| DFM Industrial 25 | 40 |

| DFM Industrial 7 | 25 |

| Nominal measuring chamber volume, l | |

| DFM Industrial 25 | 1.0 |

| DFM Industrial 7 | 0.1 |

| Mean time before recalibration* | |

| DFM Industrial 25 | 60 000/10 |

| DFM Industrial 7 | 60 000/10 |

Measurement range and accuracy

| Starting* flow rate, m3/h | |

| DFM Industrial 7 | 0,02 |

| DFM Industrial 25 | 0,5 |

| Minimum flow rate, m3/h | |

| DFM Industrial 7 | 0,72 |

| DFM Industrial 25 | 2,5 |

| Maximum flow rate, m3/h | |

| DFM Industrial 7 | 7,2 |

| DFM Industrial 25 | 25 |

| Inaccuracy** up to, % | |

| DFM Industrial 7 | ±0,5 |

| DFM Industrial 25 | ±0,5 |

Specification

| MAX flow rate | |

| DFM Industrial 7 | 7.2 м3/h |

| DFM Industrial 25 | 25 м3/h |

| MAX pressure | |

| DFM Industrial 7 | 1.6 / 6.4* MPa *on request for flange connection |

| DFM Industrial 25 | 1.6 / 6.4* MPa * on request |

| Interface | |

| DFM Industrial 7 | |

| Kinematic viscosity of liquid | |

| DFM Industrial 7 | 0.55-300 mm2/s (cSt) |

| Ambient operation temperature | |

| DFM Industrial 7 | from -20 to +60 °С |

| Operating principle | |

| DFM Industrial 7 | oval gears rotation |

| Connection to pipeline | |

| DFM Industrial 7 | flange, thread |

| Battery lifetime | |

| DFM Industrial 7 | up to 36 months |