Customer

The customer, a telematics system provider, has been operating in the South African market for over 25 years. Typically, the company installs a basic set of telematics equipment – fuel level sensors, GPS tracking devices – and connects the equipment to a telematics service. The company’s clients include more than 200 automotive enterprises and diesel generator fleets.

Machinery

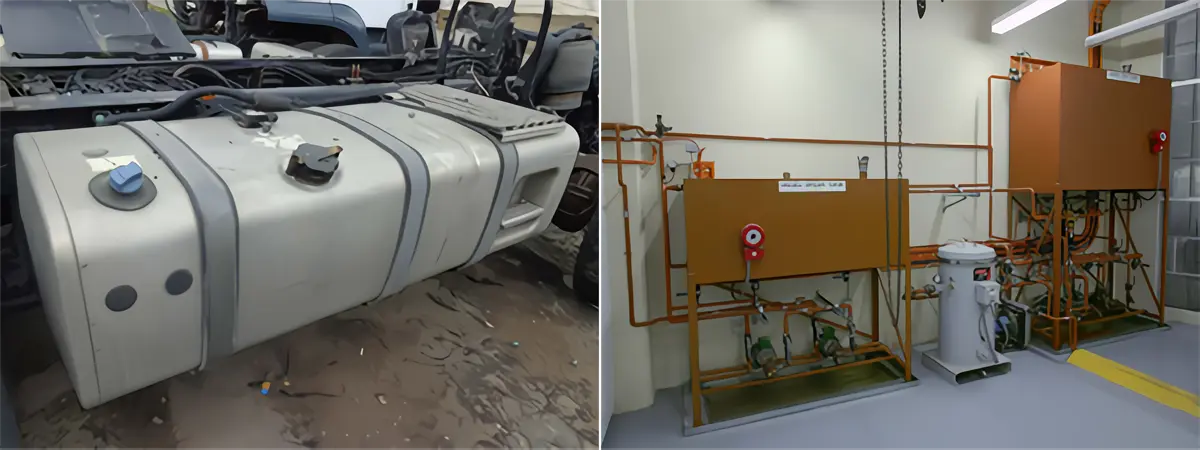

DUT-E CAN fuel level sensors are installed in the fuel tanks of various vehicles and stationary objects. Most of them go into trucks and diesel generators.

Fuel tanks have different shapes and sizes, from 100 liters (small commercial vehicles) to several thousand liters (big tanks for storing fuel for many diesel generators).

The fuel tank of a truck (left) and fuel storage tanks for diesel generators (right)

Task

A precise fuel sensor is needed to correctly measure how much fuel is in the tank and to alert about refueling and draining. The client has been using DUT-E CAN sensors since 2015. The sensor measures the fuel level very finely, in 0.1 mm steps, and sends data about the level, volume, and temperature of the fuel in the tank to the online GPS tracking system.

For accurate operation of fuel monitoring system, tank calibration is required. Tank is filled with fuel in portions from a measuring container, and after the level stabilizes, the data is manually entered into a table.

Disadvantages of manual tank calibration:

- Very time-consuming – it takes up half of the installation time.

- High risk of errors due to human factors.

The customer wanted to streamline fuel sensor installation process, eliminate possible mistakes and improve overall installation costs.

Solution

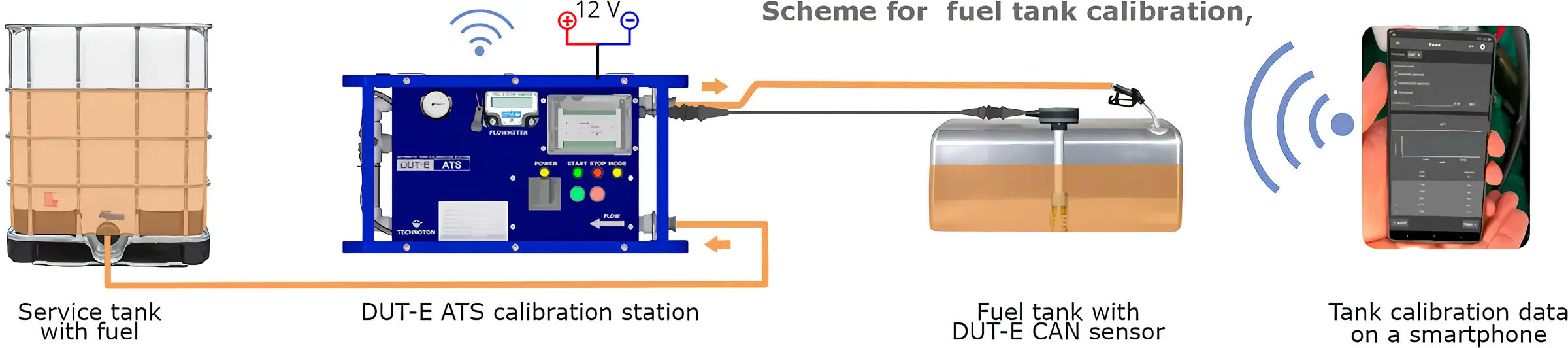

The customer was aware of DUT-E ATS automatic tank calibration station and decided to give it a shot.

DUT-E ATS is operated through a smartphone app. The installer enters the approximate volume of the tank, and the station determines the step for recording points in the tank calibration table. DUT-E ATS station continuously pumps fuel into the tank, and calibration data is automatically entered into the table.

Calibration speed of the tank is 1500 liters per hour. After calibration is completed, the station shuts off. The calibration table is saved in the sensor’s memory and in the mobile app.

Advantages of the DUT-E ATS station:

1. High calibration accuracy.

2. Elimination of human mistakes.

3. Protection against pump overheating.

4. Protection against excessive fuel pressure and air into fuel hoses.

5. Lightweight and compact size.

Gregory Voleiko, sales department head at Technoton

“In the South African market, there are many telematics system providers. Using DUT-E ATS automatic calibration station gives our partner significant advantages over competitors:

- high accuracy of tank calibration,

- absence of calibration failures and errors,

- quicker installation of the telematics system,

- less installation costs.”

Result

One of the customer’s installation teams had been using DUT-E ATS automatic calibration station consistently for several months.

Time taken for tank calibration has been reduced threefold – from 90 to 30 minutes.

During calibration, equipment installer can perform installation and setup work on tracking device – entire equipment set is installed twice as fast. The Customer can perform several times more installations with the same number of employees.

Technical Director of the Customer*

“ DUT-E ATS automatic calibration station fully met our expectations. People get tired, but a machine always works precisely – calibration is carried out without failures and errors. Our clients appreciate superior data accuracy and the shorter vehicle downtime during installation compared to our competitors, because their fleet is getting back to business swiftly.“

*Data is hidden from public access to comply with GDPR requirements. Details on the project can be disclosed upon signing NDA and with the consent of our partner.