Diesel generators fuel consumption monitoring

- Genset monitoring system:

Diesel generators fuel consumption monitoring

![]() Customer:

Customer:

mobile communication systems installation, Nigeria

![]() Task:

Task:

remote fuel consumption monitoring of genset for GSM base stations

![]() Machinery:

Machinery:

diesel generators

![]() Solution:

Solution:

Genset monitoring system:

- DFM fuel flow meter,

- CANUp telematics gateway,

- ORF4 telematics service

![]() Result:

Result:

- fuel costs reduced by 15%,

- uninterrupted operation of the DG network,

- unauthorized fuel drains are excluded

Customer

Company* has started its operation in the Nigerian market more than 30 years ago. The field of activity is a turn-key installation of telecommunication solutions. The company installs GSM masts and towers, radio frequency repeaters, as well as related infrastructure such as residential and equipment premises, diesel generators, solar and hybrid batteries and other power equipment.

Machinery

The majority of objects installed by customer are located in remote areas of Nigeria. As a rule, there is no stationary power supply in such places. The main source of electricity for such facilities is a diesel generator.

The company is working with 15 to 100 kVA generators. Customer are using equipment of various manufacturers such as SDMO, Perkins, York, Fireman.

Diesel Generator SDMO M 126

Task

Diesel generator that provides power supply on the Customer’s facility (GSM mast)

Tasks to be solved:

- accurate fuel consumption measurement of generator engine,

- measure the remaining fuel in the tank/reservoir,

- prevent unauthorized draining of fuel.

The fleet of generators at facilities is diverse. Fuel consumption from site to site can vary from 10 to 40 l/h.

The Customer needs accurate mechanisms for objective monitoring of generators fuel consumption. The fuel consumption values provided in generator data sheets are based on ideal operating conditions and are generally unrealistic. They cannot be relied upon when planning the cost of fuel and lubricants.

If the consumption data in the data sheets is overestimated, then an unaccounted amount of fuel may be observed and it can be appropriated by the maintenance personnel. If the data is underestimated, then the fuel in the tank may end ahead of time. This will stop the generator and stop the operation of the unit in general.

Solution

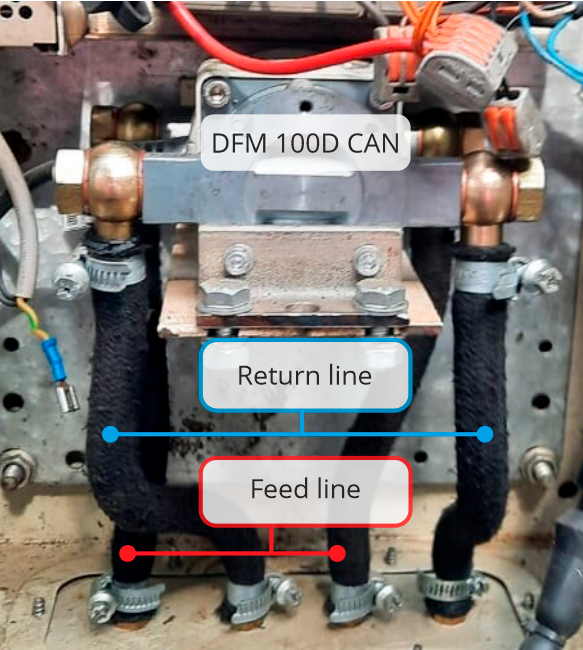

Technoton proposed to install a fuel consumption monitoring system consisting of a DFM 100D differential fuel flow meter with CAN J1939 interface and CANUp telematics gateway sending data to ORF telematics service.

Fuel is supplied to the generator engine from an external tank along the feed line. Excess fuel flows back from the generator engine into an external tank through the return line. DFM 100D fuel flow meter has two measuring chambers – for the feed and return lines. Installation of the flow meter is carried out without changing the fuel system.

The flow meter electronics processes and transmits over 40 Counters and Operating Parameters to CANUp gateway. Among them one can find instant consumption in the feed and return lines. This data can be used to plan replacement of engine consumables based on their actual condition.

CANUp telematic gateway receives the data from the DFM 100D flowmeter and transmits them to ORF telematic service.

Real-time genset fuel consumption monitoring system composition

Differential fuel flow meter installation in a genset system

Irina Radiminskaya, Technoton

“The major task of the Customer is to track the fuel consumption of each generator online and the remaining fuel in the tanks as well as to identify cases of theft of fuel from mains.

Technoton fuel consumption monitoring system displays instant fuel consumption data with an inaccuracy of ±3%. ORF service generates fuel reports for the selected period.

Analysis of these reports and fuel filling data provides information on the remaining fuel in tanks and identifies possible fuel theft.”

Result

Customer has started the installation of the flowmeters on the sites on 2019 and at the beginning of 2022, DFM fuel flow meters and CANUp telematics gateways have been installed on 40 generators.

Customer’s specialists monitor fuel consumption at each facility. The telematic service generates analytical reports on fuel consumption for any chosen period of time. Based on these reports, fuel delivery to the facilities is optimized. The risk of work stoppage due to running out of fuel is reduced to zero. The drains from the generator fuel supply system have stopped and the work with fuel at sites has been optimized. This resulted in 15% reduced fuel consumption.

Customer’s company representative*

“Fuel monitoring system provided by Technoton gives us real-time information about fuel consumption of each generator, and also provides analytical reports on fuel consumption over any period of time. Apart from other important data, DFM flowmeter is providing such parameter as generator running hours. It means that we can obtain actual data of generator running time and detect whether the generator was running in the chosen period of time or not – this is a very important factor for us.

The installation of the system was carried out by our specialists with the remote assistance of Technoton technical department engineers. Our company plans to install the system at all operating facilities. New facilities will be put into operation only with an installed fuel consumption monitoring system.”

*Data is hidden from public access to comply with GDPR requirements. Details on the project can be disclosed upon signing NDA and with the consent of our partner.