The customer

The plant has been operating in Maribor (Slovenia) since 1946. Main plant’s specialization is a production of school, intercity and airport buses (buses for delivering passengers from airport terminal to aircraft).

![]() 300+ employees

300+ employees

![]() 400+ airport buses are manufactured yearly

400+ airport buses are manufactured yearly

![]() 70+ years in business

70+ years in business

The Machinery

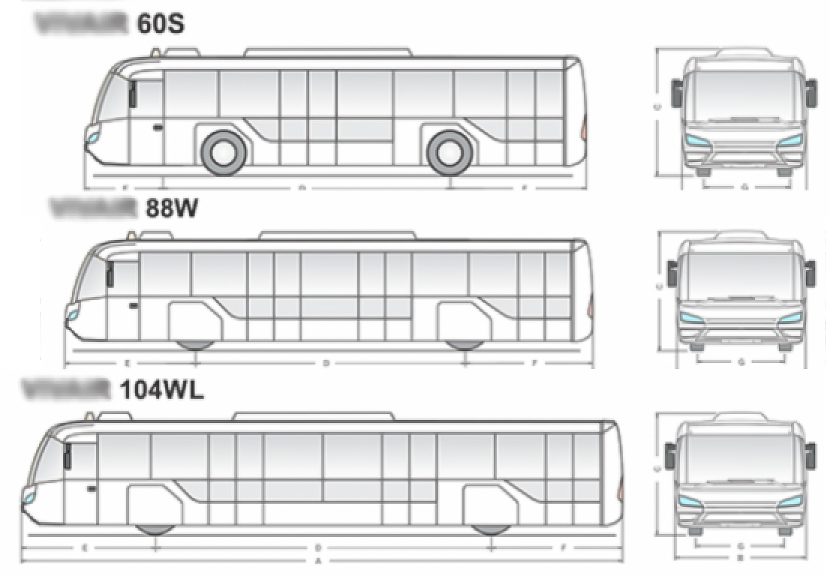

Airport buses are the most famous products of the plant. They deliver passengers from airport terminal building to aircraft and back. This buses operate in dozens of airports in European Union, Middle East, Russia and Ukraine.

Buses are equipped with MAN D0836 LOH 41 engines, 176 kW, aggregated with automatic transmission. Volume of fuel tank is 190 liters.

Main requirement to bus platform is the maximum passenger capacity. In addition, for the convenience of boarding and disembarking passengers, a bus must be low-floor. Based on these requirements, overall dimensions of bus and placement of main parts and components is designed.

The Task

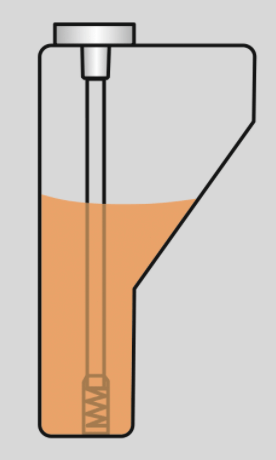

Due to the peculiarities of bus design, fuel tank of VivAir buses has specific shape – a height of about a meter, very narrow at the bottom and wide at the top (see picture).

Standard float (lever) fuel level sensor used in road trucks is not able to measure fuel level correctly. The reason is its design: sensor’s lever cannot move freely over the entire height of the tank. For such a tank, development of a special design of sensor is required.

Representatives of partner’s company contacted several manufacturers of float sensors, but prices of non-standard sensors in the quantities necessary for partner (about 400 units per year) did not fit into the project cost, in addition, delivery time was too long.

DUT-E in airport bus fuel tank

The Solution

To monitor fuel in tanks of buses, EU distributor of Technoton products (Wagencotrol company) offered DUT-E AF fuel level sensors of a custom design.

DUT-E AF has a capacitive principle of operation, there are no movable parts used in design, what ensures high reliability. The sensor measures volume of fuel in tank with high accuracy – measurement inaccuracy is within 1%. Since the sensor’s tubes reach almost to the bottom of tank, this allows to measure fuel level and volume from lowest possible to maximum possible point.

By special order of the partner, DUT-E AF sensors of a specific length were made – the length of 960mm is corresponding to the height of bus tank. This allowed to install sensor in fuel tank without additional time loss for trimming or extending the length of measuring probe of sensor.

Calibration table for the tanks of buses, where DUT-E AF were installed, as well as all necessary signal processing settings were stored in internal memory of DUT-E AF.

Yury Lavrentiev,

Wagencontrol s.r.o. (Technoton Distributor)

“We offered TAM-EUROPE to make a customized version of DUT-E AF fuel level sensors, fully adapted and configured for specific fuel tanks. At their factory, the sensor is just installed in tank and connected to dashboard – additional training on sensor configuration for plant workers is not required.

The delivery time of customized version of DUT-E AF fuel level sensor is 2-3 weeks. This time frame completely suits the customer and allows them convenient planning of purchase of components for production.”.

The Result

In 2017, specially manufactured modification of DUT-E AF saved about 40% of the budget allocated for this type of components.

In addition, plant has gained additional flexibility in production planning and formation of order for components – delivery to partner warehouse takes 2-3 weeks from the moment of sending the order to Wagencontrol s.r.o.

Thus, the partner received a ready-for-use product that fully complies with the requirements of design documentation. During bus assembly process, it is only needed to install the sensor in a tank and connect signal cable to a standard analog-to-digital converter, from which the signal is transferred to dashboard.

“We spent a lot of time looking for suitable fuel level sensors for VivAir buses. Proposals of other suppliers did not suit us either because of design, or because of price and delivery time. DUT-E AF functions exactly as we expected. It is very important for us that we get the sensors already fully configured, having required length of measuring probe and with a special mounting plate made according to our drawings.

Thank you for very good and high-quality product, which we will continue to install on VivAir buses.”

CEO of partner company