![]()

Remote

diagnostics

![]()

Motion

monitoring

Real-time vessel monitoring – fuel control and operational parameter tracking

Technoton telematics for marine and river vessels provides advanced monitoring of fuel consumption, engine performance, and critical operational parameters of onboard equipment, including generators and boilers. The ship monitoring system helps optimize fuel efficiency, reduce operational costs, enhance predictive maintenance, and ensure compliance with environmental regulations—improving overall fleet performance and safety.

The solution is suitable for small and medium-sized vessels, including tugboats, ferries, bunkering vessels, dredgers, barges, fishing, and service vessels. Data monitoring is available both onboard and remotely via an online maritime telematics service.

The key component of Technoton’s solution is the fuel consumption monitoring system, which enables:

- Reducing fuel costs and optimizing vessel performance.

- More accurate CO₂ emissions calculations to comply with environmental regulations.

- Implementing predictive maintenance, minimizing the risk of failures and downtime.

Real-time vessel monitoring – fuel control and operational parameter tracking

The solution is suitable for small and medium-sized vessels, including tugboats, ferries, bunkering vessels, dredgers, barges, fishing, and service vessels. Data monitoring is available both onboard and remotely via an online maritime telematics service.

The key component of Technoton’s solution is the fuel consumption monitoring system, which enables:

- Reducing fuel costs and optimizing vessel performance.

- More accurate CO₂ emissions calculations to comply with environmental regulations.

- Implementing predictive maintenance, minimizing the risk of failures and downtime.

![]()

![]()

Remote diagnostics

- Detection of abnormal fuel consumption

- Decoding of DTC error codes

- Alerts on abnormal parameter values

![]()

Vessel movement tracking

- GPS location monitoring

- Tracking navigation routes

![]()

![]()

Vessel movement tracking

![]()

- GPS location monitoring

- Tracking navigation routes

Remote diagnostics

![]()

- Detection of abnormal fuel consumption

- Decoding of DTC error codes

- Alerts on abnormal parameter values

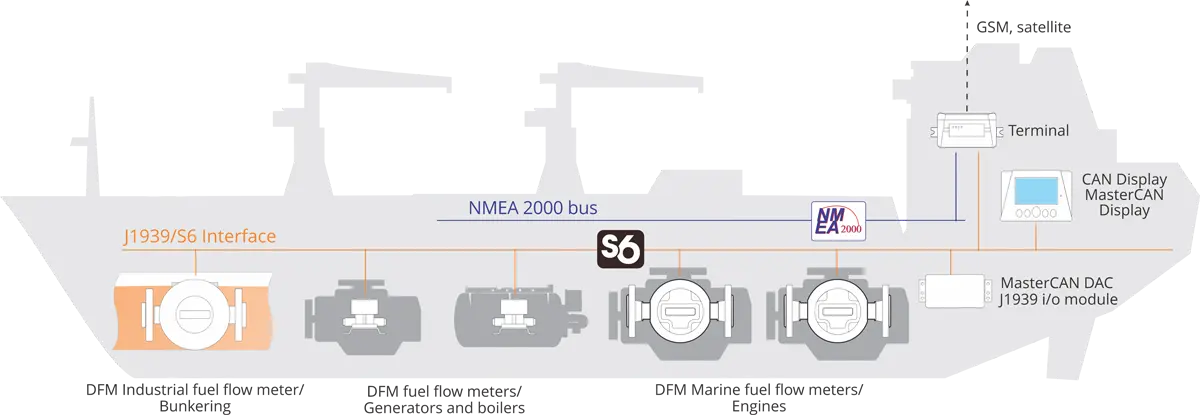

Architecture of remote ship monitoring and fuel control systems

Technoton offers specialized fuel monitoring telematics solutions tailored for both coastal/inland vessels and long-distance maritime ships, enhancing operational efficiency and safety.

Coastal and inland vessels

For small to medium-sized coastal and inland vessels, Technoton provides a standalone monitoring system that offers:

- Comprehensive fuel management

Accurate tracking of fuel consumption across all consumers, including main and auxiliary engines, generators, and boilers, as well as precise monitoring of fuel levels in tanks. - Operational parameter monitoring

Real-time oversight of engine performance metrics, generator statuses, and boiler operations to ensure optimal functionality. - Navigation tracking

Continuous monitoring of vessel position, speed and route to enhance navigation safety and efficiency.

Data is collected using Technoton’s sensors and flow meters, with the flexibility to integrate third-party sensors. Monitoring and data analysis can be performed onboard and transmitted via GSM to Technoton’s shore-based telematics service.

The system’s compatibility with protocols such as NMEA2000, CAN, Modbus, Bluetooth, and others ensures seamless integration into existing monitoring infrastructures. Additionally, integration via API into third-party fleet monitoring and management software is available, enhancing system versatility.

Ships for the long haul

For medium-sized long-distance marine vessels, Technoton’s telematics equipment functions as an integrated onboard system, providing:

- Precise fuel monitoring

Detailed measurement of fuel consumption to optimize fuel efficiency and reduce operational costs. - Comprehensive equipment oversight

Monitoring of main and auxiliary engines, generators, and boilers to ensure reliable performance during extended voyages. - Performance and emissions monitoring

Daily fuel tracking via noon reports supports vessel decarbonization—each tonne of fuel saved means fewer emissions and improved compliance.

The equipment’s compatibility with the NMEA2000 marine bus and Bluetooth data transmission capabilities allows for seamless integration into the vessel’s satellite monitoring system, ensuring continuous data availability for informed decision-making.

Architecture of remote ship monitoring and fuel control systems

Technoton offers specialized fuel monitoring telematics solutions tailored for both coastal/inland vessels and long-distance maritime ships, enhancing operational efficiency and safety.

Coastal and Inland Vessels

For small to medium-sized coastal and inland vessels, Technoton provides a standalone monitoring system that offers:

- Comprehensive fuel management

Accurate tracking of fuel consumption across all consumers, including main and auxiliary engines, generators, and boilers, as well as precise monitoring of fuel levels in tanks. - Operational parameter monitoring

Real-time oversight of engine performance metrics, generator statuses, and boiler operations to ensure optimal functionality. - Navigation tracking

Continuous monitoring of vessel position, speed and route to enhance navigation safety and efficiency.

Data is collected using Technoton’s sensors and flow meters, with the flexibility to integrate third-party sensors. Monitoring and data analysis can be performed onboard and transmitted via GSM to Technoton’s shore-based telematics service.

The system’s compatibility with protocols such as NMEA2000, CAN, Modbus, Bluetooth, and others ensures seamless integration into existing monitoring infrastructures. Additionally, integration via API into third-party fleet monitoring and management software is available, enhancing system versatility.

Ships for the long haul

For medium-sized long-distance marine vessels, Technoton’s telematics equipment functions as an integrated onboard system, providing:

- Precise fuel monitoring

Detailed measurement of fuel consumption to optimize fuel efficiency and reduce operational costs. - Comprehensive equipment oversight

Monitoring of main and auxiliary engines, generators, and boilers to ensure reliable performance during extended voyages. - Performance and emissions monitoring

Daily fuel tracking via noon reports supports vessel decarbonization—each tonne of fuel saved means fewer emissions and improved compliance.

The equipment’s compatibility with the NMEA2000 marine bus and Bluetooth data transmission capabilities allows for seamless integration into the vessel’s satellite monitoring system, ensuring continuous data availability for informed decision-making.

Smart sensors and tools for ship telematics and fuel control

Vessel parameters monitored by telematics system

FUEL

• Instant flow rate in propulsion engines, generators, boilers

• Total fuel consumption

• Total fuel used in “Idle” and “Optimal” modes

• Fuel temperature

• Fuel level in tanks

• Remaining on board fuel oil/lube oil/diesel

ENGINE

• Engine hours (running time)

• Operating time in “Idle” and “Optimal” modes

• Coolant temperature, Engine oil pressure

• Total CO2 emission, Hourly CO2 emission

• Engine operating mode: Idle/Optimal/Overload

• Average RPM of propulsion engines

GENERATORS AND BOILERS

• Power network voltage

• Battery voltage

• Energy production per liter of fuel

• Generator (Phase) frequency, voltage, current

• Boiler steam and water pressure

• Boiler water, steam, and flue gases temperature

DATA AND EVENTS

• Events “Power on/off”, “Data cheating” “Interference” etc.

• Operating time in event modes

• Fuel flow meter cheating, engine overspeed, boiler overheating

• Ship position (GPS latitude and longitude)

• Average speed in knots

• Information from standard and additional analog sensors

Examples of completed projects

Our vessel telematics projects

Ventspils port, Latvia

Task: monitoring of fuel consumption and prevention of manipulations with fuel.

Solution: DFM 250 AK fuel flow meters for gensets and DFM 250 DK for engines.

Transportation company

Task: fuel consumption monitoring of river vessels and optimization of routes.

Solution: DFM 250CCAN fuel flow meters, DFM 100CCAN fuel flow meters, GPS-trackers.