Fuel flow meters

Fuel flow meter

DFM fuel flow meter is designed for fuel consumption measurement of vehicles and stationary machines, and for monitoring machinery operation hours in different engine working modes. DFM also can be used for monitoring of heating oil and other liquids with kinematic viscosity of 1.5-6 mm2/s.

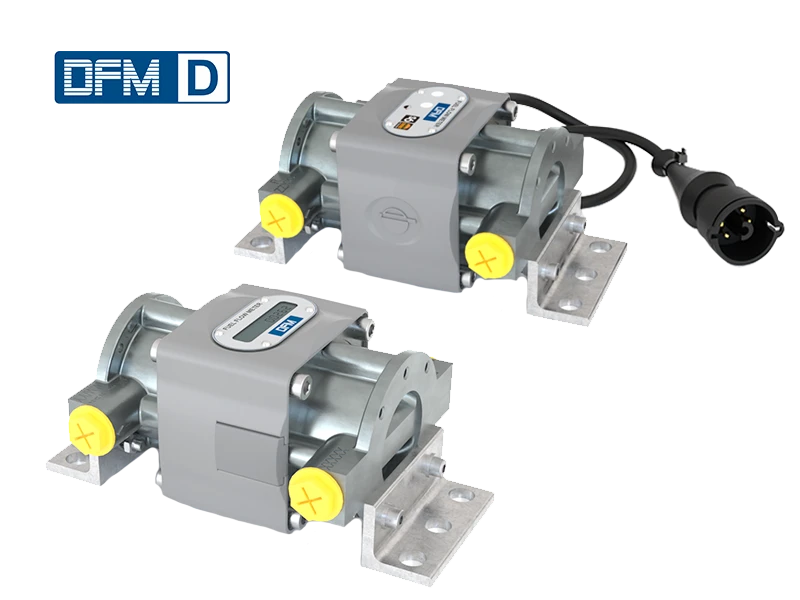

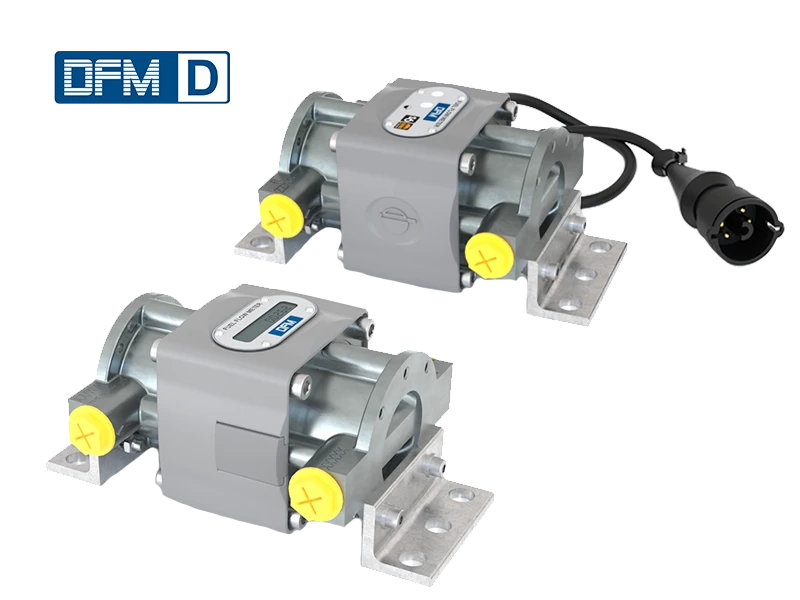

Differential flow meter

DFM D differential fuel flow meter is designed for diesel fuel consumption measurement of vehicles and stationary engines, which has Common Rail or pump nozzle fuel injection systems. DFM D also provides information on flow rate in feed and return lines and can be used for monitoring consumption of heating oil and other similar liquids.

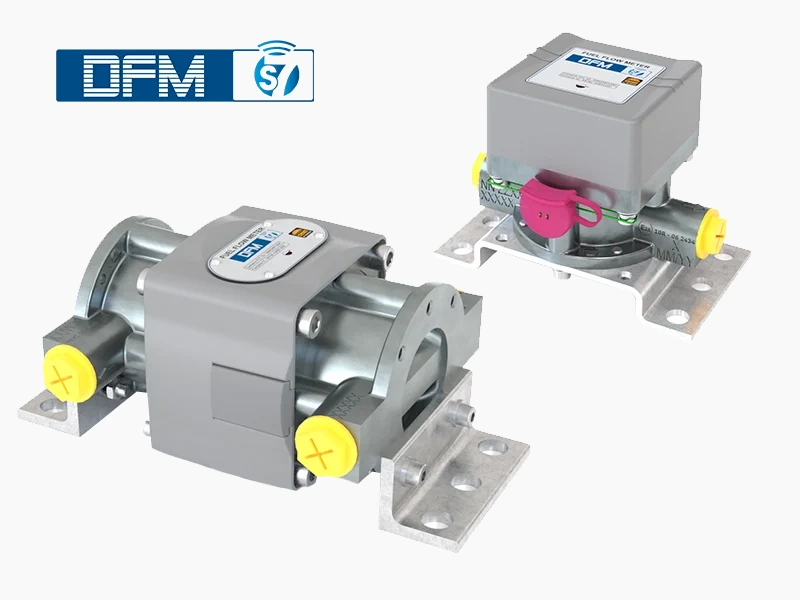

Wireless fuel and oil flow meter

DFM S7 – new fuel flow meters with wireless data transfer over BLE (Bluetooth low energy). Data on fuel consumption (fuel rate) and vehicle operation time is sent simultaneously to several devices: for telematics and remote machinery monitoring purposes – to GPS tracker, for autonomous fuel monitoring – to a smartphone or tablet with Bluetooth.

Flow meter for heavy machinery

DFM Marine is a fuel/oil flow meter used for heavy machinery and measures flow rates up to 4,000 L/h. It provides information on fuel consumption and machinery operation hours, including breakdown to various operation modes. DFM Marine can be used as a part of telematics or GPS tracking systems, as well as autonomous solution for fuel monitoring.

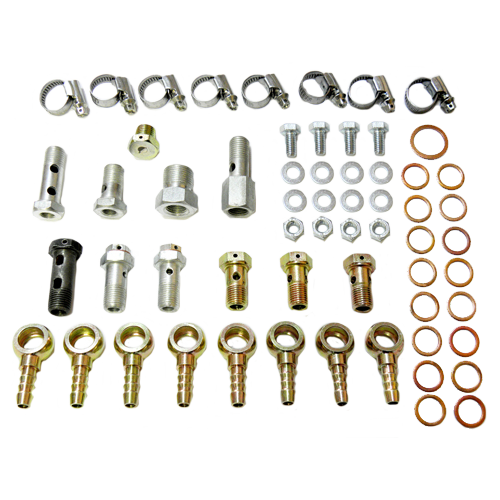

Accessories for installation of Fuel flow meters

Frequently Asked Questions

The DFM fuel flow meter is a direct fuel consumption measurement device installed directly in the engine’s fuel lines, measuring the fuel flow from the tank to the engine and back. DFM enables precise measurement of fuel consumption and engine operating time under various load conditions — idle, optimal, and overload — as well as calculation of CO₂ emissions based on the engine’s actual fuel consumption.

DFM fuel flow meters are used to monitor fuel consumption in commercial vehicles, heavy machinery, and stationary systems operating on diesel fuel, heating oil, and similar fuels. Applications include road maintenance equipment, construction and mining machinery, agricultural machinery, marine vessels, railway equipment, diesel generator sets, boiler systems, departmental fuel stations, and fuel tank trucks.

Fuel consumption parameters and the current consumption mode measured by the DFM fuel flow meter can be used for real-time equipment monitoring, including remote diagnostics and performance verification, as well as monitoring operator performance and compliance with operational regulations.

Analytical data — such as total fuel consumption and engine operating time under various load conditions — are used to assess fleet efficiency, prevent fuel theft from fuel lines, track engine operating hours, and plan maintenance schedules.

DFM flow meters are available with various output interfaces, including CAN J1939, Modbus RTU, BLE, and pulse output. A DFM flow meter can be connected to a telematics gateway (GPS tracking), a CAN display, a diesel generator control panel, a marine deck display, or any other device supporting the corresponding interface. A mobile application can also be used to monitor DFM readings via the wireless BLE interface.

When integrated into a GPS tracking system, data from the DFM flow meter is transmitted to cloud-based software, where it is visualized as charts and tabular reports.

The DFM, DFM D, and DFM S7 product lines operate on the “chamber–ring” principle. Fuel enters the measuring chamber, where its pressure sets a ring in motion. The ring rolls along the inner surface of the chamber, displacing a fixed volume of fuel. The electronic unit counts the number of ring revolutions, thereby determining the fuel flow rate.

The DFM Industrial product line operates on the “oval gear” principle — the general concept is similar to the “chamber–ring” design, but uses two intermeshing oval gears as the primary transducer.

DFM fuel flow meters are direct measurement instruments for fuel consumption and fuel consumer operating time, offering the following advantages:

- High measurement accuracy, with an error margin from ±0.5% to ±3% depending on the model.

- Large set of monitored fuel consumption parameters — up to 40 parameters from a single flow meter.

- Capability to build a fuel monitoring system for multiple consumers — up to 32 DFMs in a single network using S6 Technology.

- Wide product range — models available for different fuel flow rate ranges, interface types, and housing materials.

- High quality and metrological verification — each flow meter is factory-tested, with quality control certified to ISO 9001.