Solution for KJ Power KJT120ASB diesel generator based on Moteurs Baudouin engine

Installation of DFM 100D fuel flow meter, DUT-E CAN fuel level sensor, MasterCAN RS2CAN converter, which receives data from DATAKOM D500 controller via Modbus RS-485 protocol, CANUp Genset telematics gateway. As a result of the installation, the customer company received access to a personal account on UNUM server, where technical specialists can view and analyze all possible operating parameters of the diesel generator, such as:

- fuel consumption (instantaneous, total);

- engine operating time (to control the frequency of maintenance);

- the exact amount of fuel in the tank;

- alternator operating modes;

- signals from analog sensors of the diesel generator, and etc.

Fuel System of KJ Power KJT120ASB diesel generator

DATACOM D500 controller

Cutting the length of the DUT-E CAN fuel leve sensor

Drilling a hole for installing a DUT-E CAN fuel level sensor

Installation of DUT-E CAN fuel level sensor

DFM D100 differential fuel flow meter built into the fuel system

Setting up the equipment in Service MasterCAN service program

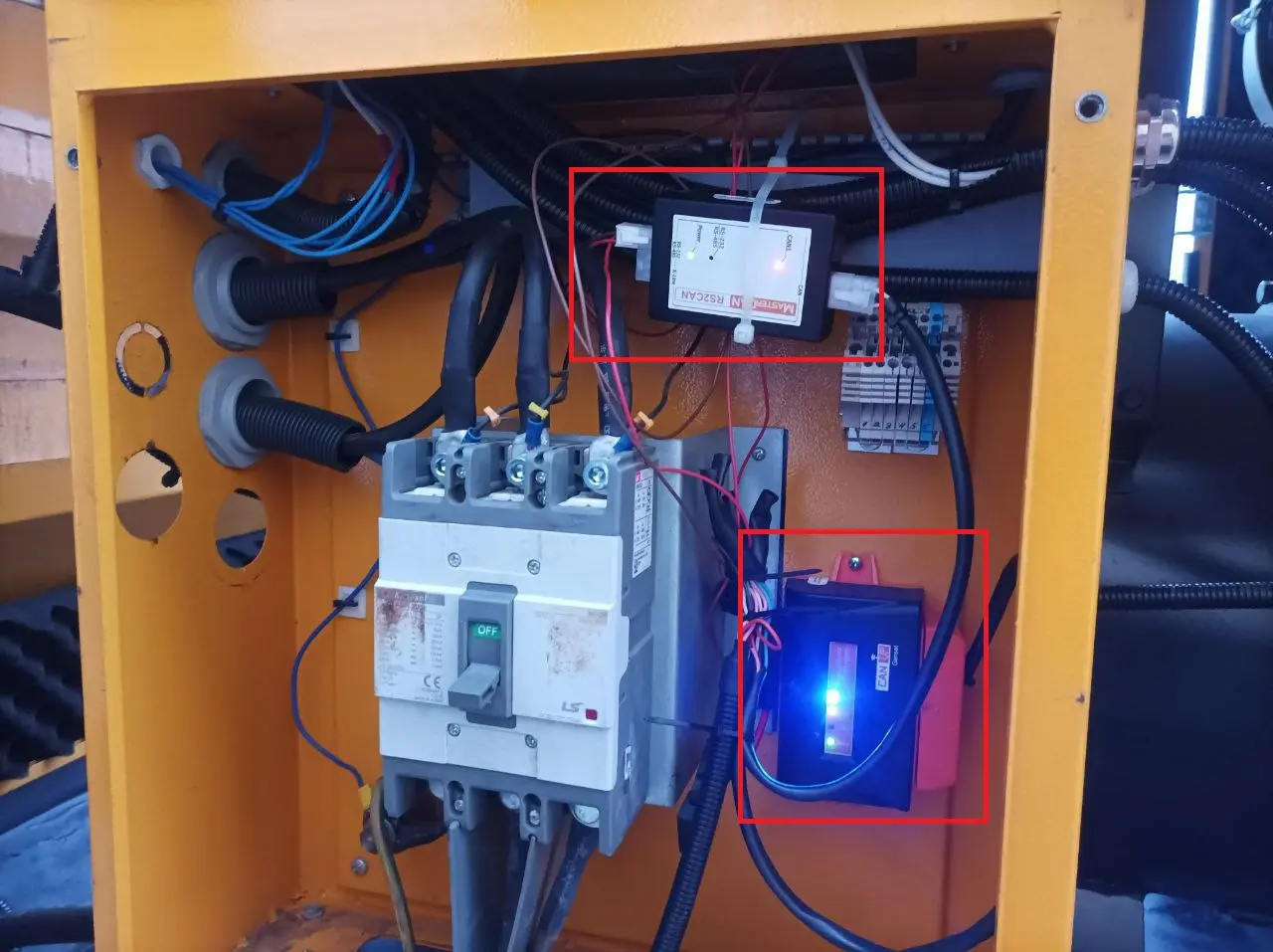

MasterCAN RS2CAN converter receives data from the controller, below is the CANUp Genset telematics gateway

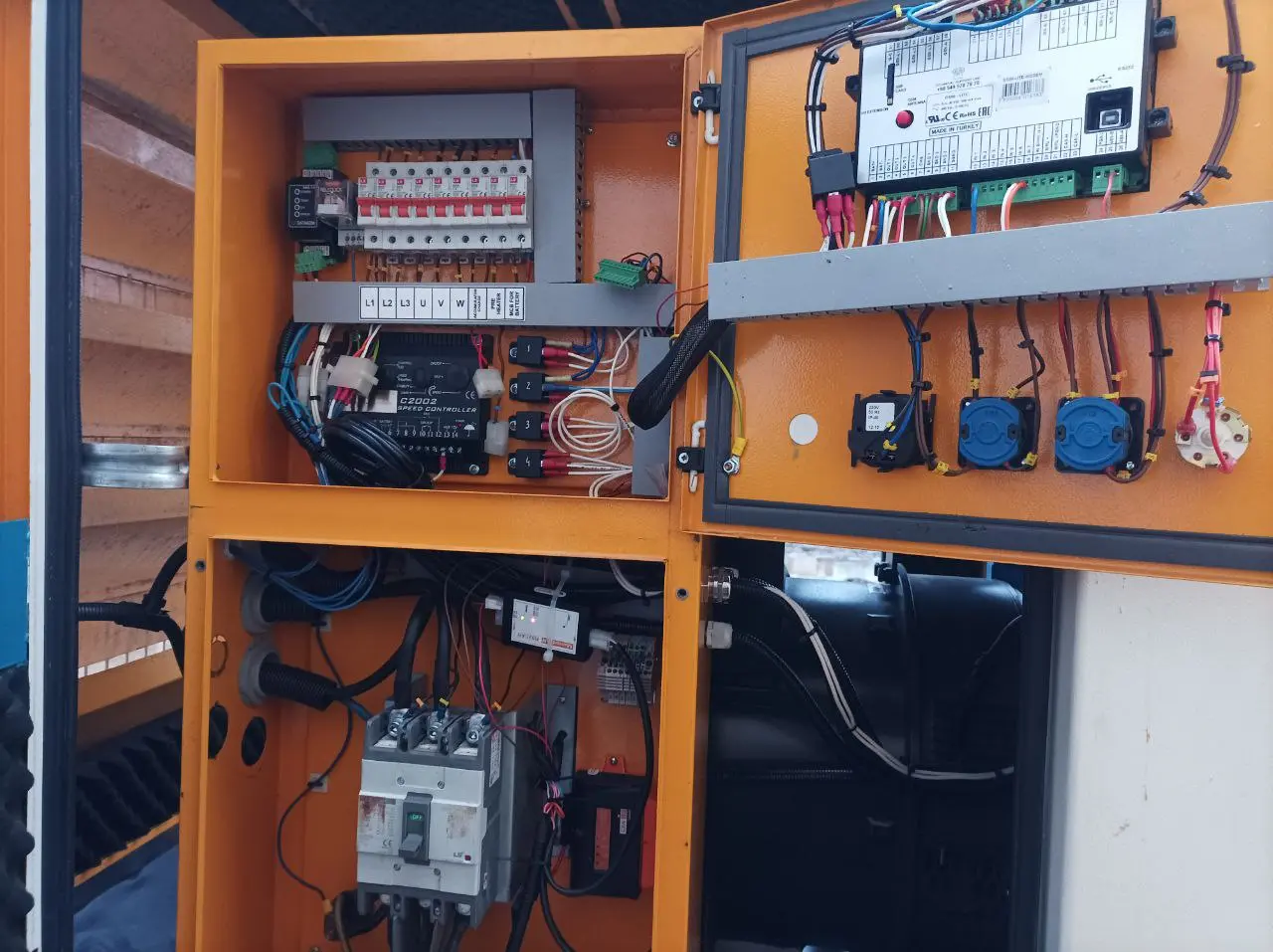

KJ Power KJT120ASB diesel generator Control Board