DFM Marine is used to monitor fuel consumption and operating time of fuel consumer with the flow rate up to 4,000 l/h. Flow meters are being used as a stand-alone solution and as a part of telematics systems (GPS tracking systems). DFM Marine is installed in fuel line into an engine/boiler/burner fuel line, where it measures fuel consumption and generates an output signal for transmission to telematics unit (GPS tracker).

DFM Marine advantages

DFM Marine fuel counter for heavy machinery has unique advantages over other fuel flow meters for water transport, locomotives, mining machinery.

1) Wider range of measured flow rate.

Consumption ranges per hours are:

- DFM Marine 1000 model : 20 – 1000 l/h,

- DFM Marine 2000 model: 40 – 2000 l/h,

- DFM Marine 4000 model: 80 – 4000 l/h

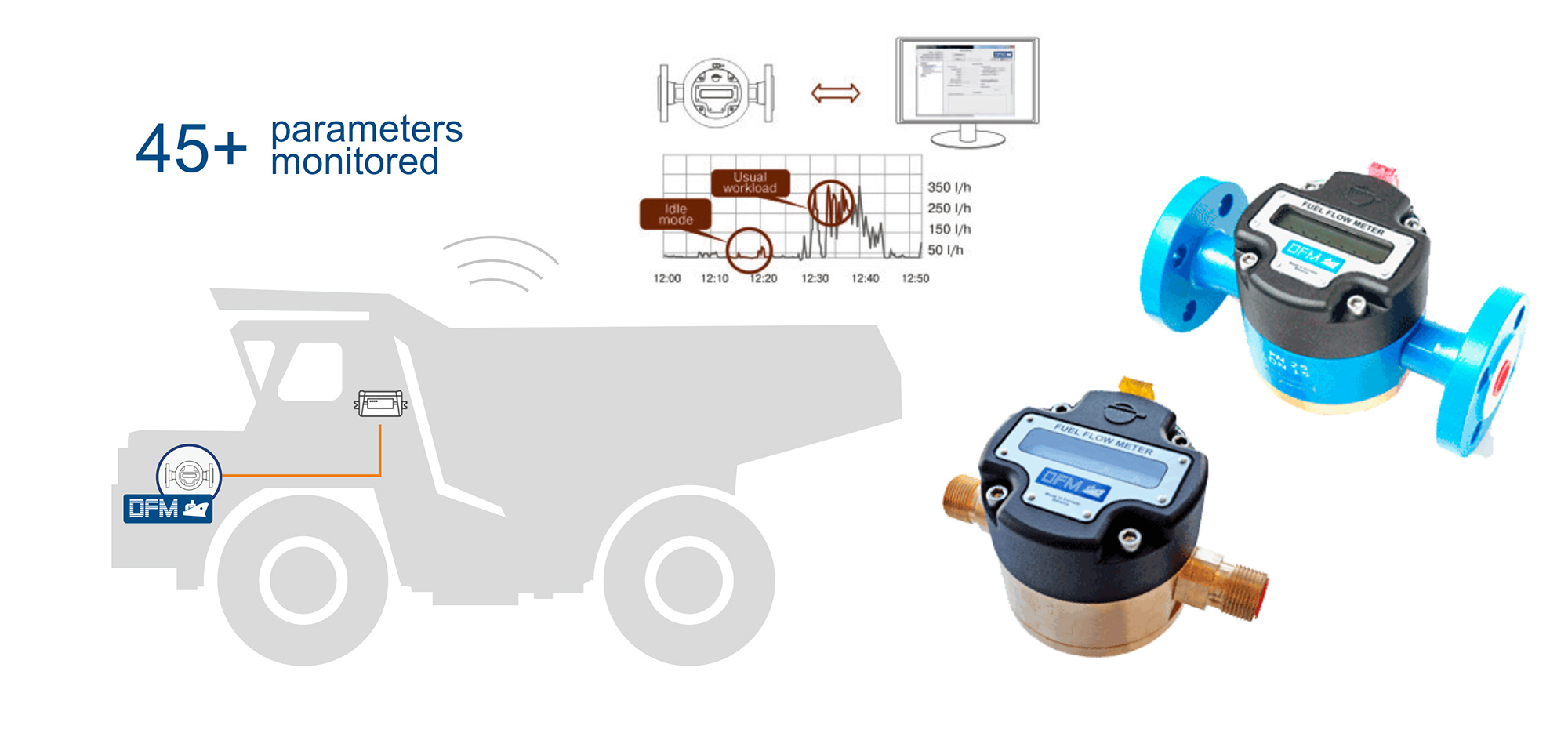

2) Extended functionality: 45 + Parameters of fuel consumption and engine operation time monitored. The received scope of data includes:

- Fuel consumption – instant (per hour), total and in “Idle”, “Optimal” and in “Overload” modes

- Engine operation time – total and in “Idle”, “Optimal” and in “Overload” modes

- Data “Tampering” and “Interference” Counters

- Total fuel consumption and operation time clearable Counter

- Temperature in the measuring chamber

- Voltage in an on-board power network

- Route fuel consumption

- Ignition condition

- Operation time from an inbuilt battery (electric power storage)

- Current and saved malfunctions

- Internal clock

- Network address etc.

3) Real-time monitoring of data Counters on in-built LCD display. 16 Counters and Parameters are displayed, among which are the following:

- Instant fuel consumption and instant differential fuel consumption (while in differential measurement mode)

- Total and total differential fuel consumption

- Total fuel consumption in “Tampering” mode

- Engine operating time total and in “Idle”, “Optimal” and in “Overload”, “Interference” (by magnetic field)

- Resettable fuel consumption Counter

- Resettable operating time Counter

4) Output interfaces: RS232/RS485 (ASCII and Modbus), CAN j1939/S6 (+ NMEA 2000) and also normalized pulse.

5) “Differential”/“Summarization” operation mode.

For operation in “Differential”/“Summarization” mode, any pair of DFM Marine CCAN flow meters is connected using S6 Technology.

Differential mode implies calculation of fuel consumption as a difference between fuel consumption measured by flow meter in feed and reverse lines. In summing mode – fuel consumption is calculated as a sum of fuel consumption measured by flow meter in first and second fuel lines.

6) Transferring and displaying data in both Metric and US measurement units (gallons).

7) Measurement inaccuracy, not more than ±0,5%.

In differential/summarization measurement mode, inaccuracy is not higher than ±1.0 % (depending on the proportion of fuel consumption in chamber of each flow meter used).

8) Up to 8 flow meters can be connected using S6 technology in one single network, powered and configured via one cable.

9) Multilevel protection against unauthorized interference in operation and data “tampering”.

10) High-quality technical support and detailed documentation.

DFM Marine implementation examples on heavy machinery

DFM Marine flowmeters were installed in heavy machinery engines supply and return fuel lines according to “pressure” mounting scheme, “Differential” operation mode is used.

The following data now is sent to GPS tracker and displayed:

- Instant differential fuel consumption

- Total fuel consumption

- Fuel consumption in supply line

- Fuel consumption in return line

- Engine operating time, fuel consumption in “Idling”, “Optimal”, “Overload”, “Tampering” mode