Mobile elevating work platforms

fuel, battery, engine, GPS monitoring

Mobile elevating work platforms

fuel, battery, engine, GPS monitoring

![]() Customer:

Customer:

heavy machinery rental and supply, Malaysia

![]() Task:

Task:

fuel tank monitoring, battery condition monitoring,

machine usage/operating condition and machine location tracking

![]() Machinery:

Machinery:

diesel / electric mobile elevating work platform (MEWP) fleet

![]() Solution:

Solution:

- DUT-E fuel sensors,

- MasterCAN DAC converters,

- CANUp telematics gateway + ORF4 telematics service

![]() Result:

Result:

implementation of predictive machinery maintenance system

Customer

Company* was founded in 2005. It is the official distributor of the world’s leading heavy machinery manufacturers – Liebherr, Genie, Axtech and Getzner. Company sells machinery in Malaysia and also leases it to local road construction companies, which excavate open-cut mining quarry.

Machinery

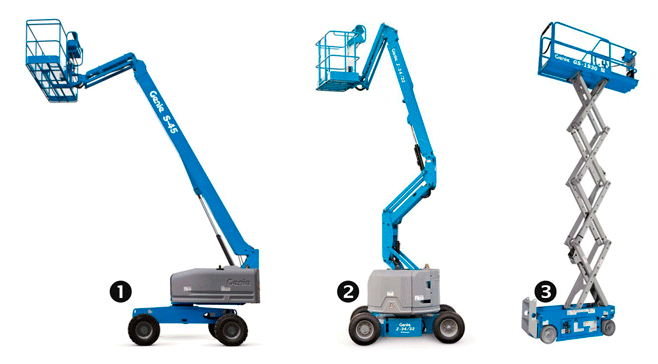

Telematics and fuel monitoring system was installed on Genie mobile elevating work platforms of various series: S (Telescopic Boom Lifts), Z (Articulated Boom Lifts), GS (Electric & Bi-Energy Scissor Lifts / Rough Terrain Scissor Lifts).

Aerial lifts have diesel engines of various models and power:

- Kubota (volume 0.5-1.1 liters, power of 10-19 kW),

- Deutz (volume 2.2-2.9 liters, power of 20-75 kW),

- Ford (volume 2, 5 l, power of 99 kW),

- Perkins (volume 1.1-2.2 l, power of 18-49 kW).

1) Telescopic Boom Lifts of S series

2) Articulated Boom Lifts snorkel lift of Z series

3) Electric & Bi-Energy Scissor Lifts/ Rough Terrain Scissor Lifts of GS series

Task

Most MEWPs are regularly leased. Lease-takers are industrial and construction companies, logistics and warehousing companies, and also firms that specialize in buildings renovation.

Under conditions of lease agreement, Customer’s company is obliged to carry out maintenance of MEWPs. Conducting planned preventive maintenance on time is a guarantee of long and uninterrupted operation of hardware.

Operation conditions of MEWPs – daily operating times and the number of descents/ascents – vary greatly. Therefore, it is impossible to carry out maintenance simply by the number of calendar days, that have passed since the start of lift platforms.

MEWPs, that are leased, operate in hundreds of facilities, located in different parts of the region. It is physically impossible to track time and operating conditions of each item.

Top management of the company decided to implement a remote monitoring system of each mobile elevating work platform to optimize maintenance costs. Main parameters that should be kept under control:

- engine running time,

- engine speed,

- fuel consumption and remaining fuel in the tank,

- turning engine on/off,

- voltage of on-board network of MEWP.

- GPS-tracking

Based on this data, a decision on terms of technical maintenance will be made.

Solution

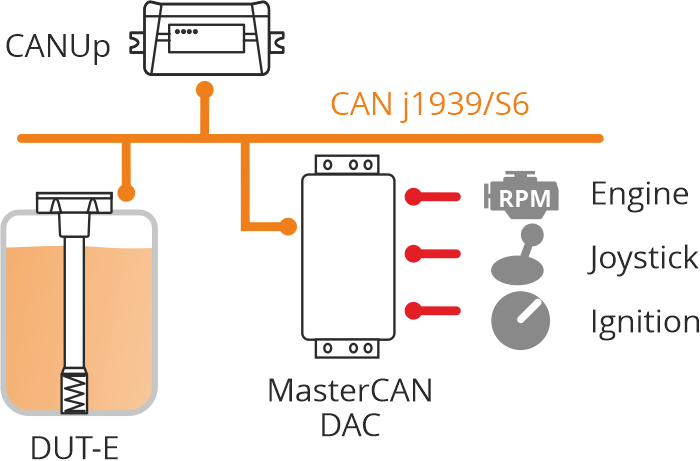

Telematics system for each vehicle is composed of:

- DUT-E fuel level sensor

- MasterCAN DAC digital-to-analog converter

- CANUp telematics gateway

All equipment units are connected using S6 Technology

and communicating over CAN J1939/71 interface.

DUT-E fuel level sensor, MasterCAN DAC converter, CANUp telematics gateway

DUT-E fuel level sensor are used for precise fuel tank monitoring and direct fuel consumption measurement, also for recording engine operation time in “idling”, “optimal” and “overload” modes. MasterCAN DAC converter gets analog signals from vehicle units and digitizes them – frequency signal for RPM measurement, joystick relay voltage indicating boom position, binary signal of ignition key on/off.

Telematics system set

Data processing, report generation and sending using 2G/3G/LTE is carried out by CANUp telematic gateway. Important CANUp features for the project:

- Plug-n-play operation with Technoton equipment – the customer saved a lot of time and efforts on configuring the system.

- Remote diagnostics of telematics equipment operability.

- Event-based report generation, e.g. when fuel tank is refilled or fuel is siphoned, when vehicle leaves geozone (which is configured inside CANUp).

- Smart alarms without online server – over email and SMS for up to 3 users.

- 10,000+ CAN parameters are supported – leaves room for scaling the system by connecting vehicle’s CAN bus or third-party equipment with J1939/71 interface.

Nikolay Fialkovsky, Technoton

“Our client faced the task of obtaining information about fuel, as well as gathering data from components and assemblies of diesel and electric lifts with different outputs. All data should be converted to unified format and transmitted to Telematics service.

Technoton proposed telematics solution, based on DUT-E fuel level sensor, MasterCAN DAC converter and CANUp telematics gateway. All hardware is connected using S6 technology. Telematics system by Technoton is a reliable and easy to install and configure solution, that provides problem solving.”

Result

More than 70 mobile elevating work platforms were equipped with telematics systems by Technoton. Tracking of running time, monitoring of fuel consumption and remaining fuel in fuel tanks, monitoring condition of electrical system/battery of MEWPs − is carried out in real-time. Thanks to this data, the customer can plan more efficiently.

Predictive Maintenance is the ultimate aim that the company wish to achieve to optimize the cost of ownership of its fleet, and minimum downtime.

It started with having a reliable system for machine data collection. With the current monitoring system, the company is able to decrease its operating cost by 10%.

Now the customer is going to equip the entire fleet with telematics system by Technoton.

Customer’s company representative*

“Technoton has proposed a comprehensive solution to solve our problem. All necessary equipment was easy to install on MEWPs without changing control elements.

Thanks to monitoring system installation, fleet management automation became possible – now we can monitor online: status of battery/on-board network, fuel consumption, location of MEWPs.

ORF4 telematics service allows online remote access to all necessary data. System of predictive machinery maintenance is based on analysis of this data.”

*Data is hidden from public access to comply with GDPR requirements. Details on the project can be disclosed upon signing NDA and with the consent of our partner.