Diesel generators (power generators, gensets) are used as a backup, auxiliary or main source of power supply. Standby diesel generators are switched on manually or automatically if there is no centralized power supply. For example, genset are used as a backup source in hospitals, banks, communication centers and other places where safety net is needed.

Auxiliary diesel generators are used at construction sites, in quarries, in production facilities – places where an additional source of energy is required to meet short-term surges in consumption.

Power generator as the main source of electricity is used where there are no power lines – remote settlements, cell towers.

Tasks of genset monitoring system

How can the monitoring system help operators and owner of genset fleets? Monitor genset operation modes and health, evaluate efficiency of operation.

- Pre-launch check.

We are talking about the collection of parameters that are important before starting the engine: battery voltage, absence of active errors and malfunctions, sufficient amount of fuel in the tank. If a malfunction is detected, the start of the power generator should be postponed if possible. This eliminates the risk of breakage and additional repair costs. - Ensuring uninterrupted operation of genset

To know how long a diesel generator is able to work, you need to know both the fuel flow rate and the balance in the tank. By the way, the introduction of automation of fuel supply increases the autonomy of the diesel generator set, and its ability to operate smoothly. - Remote diagnostics and health monitoring.

Quick detection of malfunctions and emergency (preferably automated) shutdown helps to avoid unnecessary repair costs. Remote identification of a malfunction, even before the service technician leaves, simplifies repairs and reduces costs. - Monitoring generator performance.

Analysis of genset operating parameters enables both evaluation of direct costs and detection of hidden dangers. For example, an abnormal change in instant flow rate may indicate a malfunction of the fuel system. - Reducing repair costs through predictive maintenance.

Recording real operating time of the diesel genset allows inspecting and replacing consumables and spare parts according to the actual state of a unit, and not according to the calendar. This is especially important if different units of genset fleet operate under different conditions and for various durations.

Genset monitoring system features

Based on the tasks mentioned above, diesel generator monitoring system should provide accurate measurement, remote reading, data transmission to a telematics server, as well as process automation and / or remote control of generator operation.

- Monitoring of engine parameters: fuel monitoring, RPM stability, temperature and pressure of oil and coolant, absence of errors and other indicators.

- Monitoring electrical parameters of alternator: current and voltage in phases, frequency, active and total power, Cos φ and so on.

- Diesel generator fuel monitoring stands out as a separate feature, as it deals with many inter-related tasks.

For example, the elimination of fuel theft and misuse reduces direct costs for diesel generator operation. By monitoring deviations in average fuel consumption, abnormal fuel system performance can be detected. Monitoring total fuel consumption to plan maintenance based on the actual time in operation and wear-out of a genset. - Monitoring operation environment: ambient temperature, state of cooling fans, opening / closing of casing doors and others.

- Notifications on events — launch, shutdown, emergency stop, abnormal operating parameters values. Such notifications enable the owner or operator of the diesel generator set to quickly navigate and respond to changes in working conditions.

- Reports on power generator operation. Individual and group reports that allow estimating overall figures – total hours, total power generated, total fuel consumed. These figures help in making operational (repairs, maintenance) and long-term decisions (fleet renewal, changes in internal regulations).

- Process automation. Emergency stop due to critical values of operating parameters, fuel pumping from storage tank to genset’s fuel tank and other automations. Automation of power generators eliminates human factor and increases reliability of genset operation.

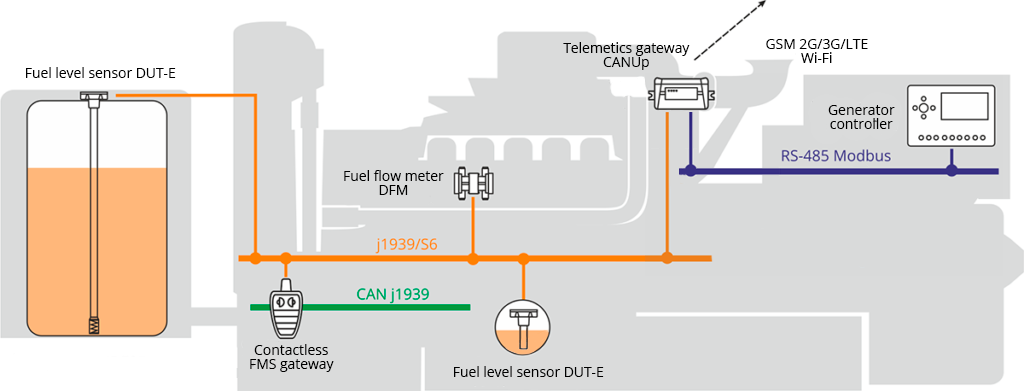

Equipment for diesel generator monitoring

DUT-E fuel level sensor

DUT-E fuel level sensors are measuring how much fuel is left in genset’s tank. In addition, the sensor measures fuel and ambient temperatures.

Parameters from the fuel level sensor:

- remaining fuel volume,

- fuel fill-up volumes,

- fuel draining/theft volumes,

- misuse of fuel and manipulation attempts,

- indirect fuel consumption (from a tank).

DFM fuel flow meter

DFM fuel flow meters measure real fuel consumption in supply and return lines of a power generator fuel system. Also, the flow meter records duration of fuel supply, what helps to account engine hours.

- Instant flow rate (fuel consumption),

- total fuel used by engine, also split by “Idling” and “Optimal” operation modes,

- total engine operation time, also split by “Idling” and “Optimal” operation modes,

- recording quantity and duration of interference and unauthorized impact on a flow meter,

- registering data tampering attempts.

MasterCAN Display 35 – CAN/J1939-display

The screens of MasterCAN Display 35 show both engine parameters and alternator parameters. Data on the screens can be used by mechanics and other staff working near the power generator.

The display can show information from dozens of connected fuel sensors, j1939 i/o modules, CAN bus readers and standard analog senders.

By the way, in low-budget monitoring system the display can be used as the only tools for displaying data, i.e. without online data sending.

CANUp telematics gateway

CANUp telematics gateway gathers data from all connected devices, generates Reports and sends them to a web-based telematics service for monitoring power generator operation.

Additionally, CANUp detects events (sharp change in parameter values) and sends alarms / notifications via e-mail and SMS.