When switching from regular fuel to another fuel type or fuel quality, the readings of regular capacitive fuel sensor with two measuring electrodes may prove to be overstated or set too low up to 50% of a real level. It can pervert data and reduce the reliability of fuel monitoring system and GPS/Glonass transport monitoring system (or stationary units monitoring system).

The most frequently, fuel tanks of machines are filled with the one and the same fuel from certain supplier – fuel station.

Vehicles, where frequent change of fuel type/quality take place

→ International trailers, trucks and buses filled with fuel on different filling stations.

Fuel quality standards vary depending on the country. It is often the case that fuel from different gas-filling stations has exclusive permittivity coefficient value although it is the one and the same fuel type.

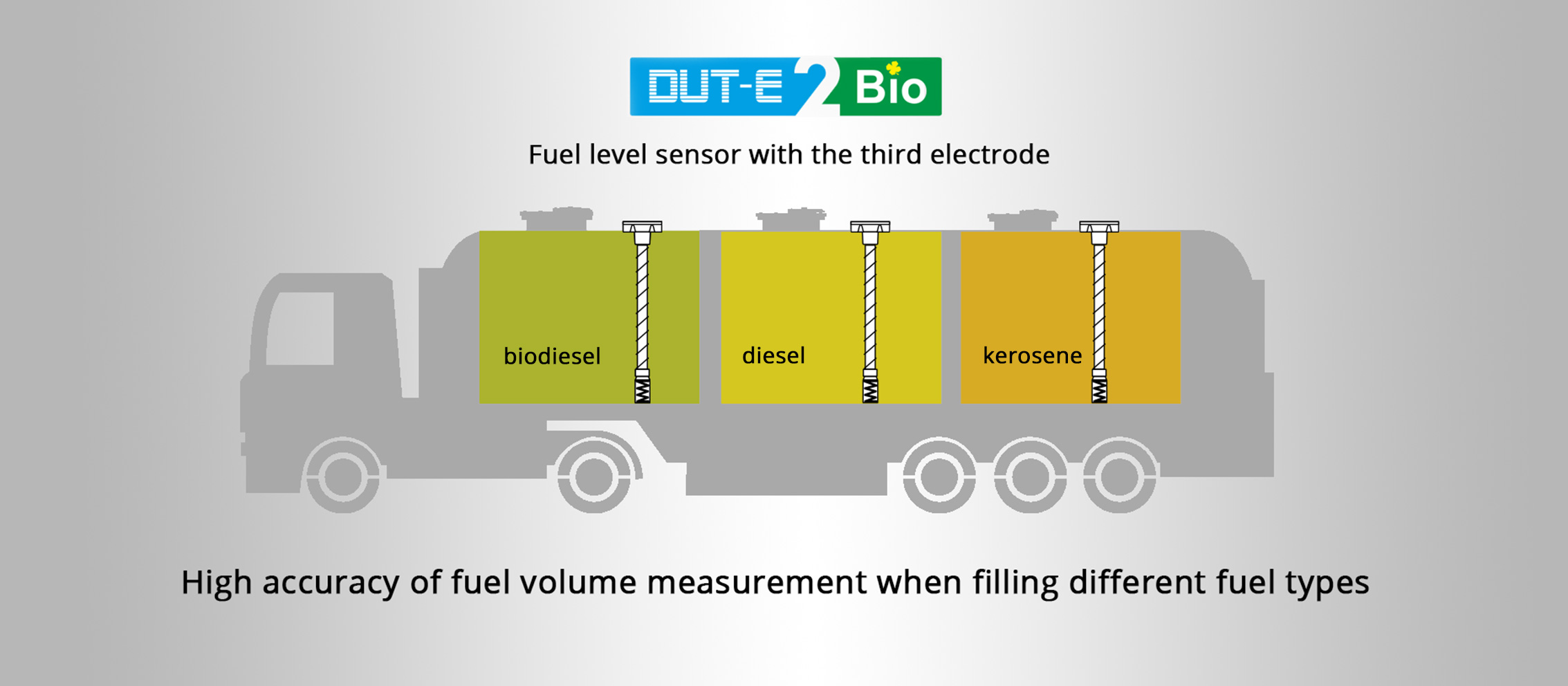

→ Fuel-servicing trucks and tanker truck filled with different fuel types every time.

The distinction between permittivity coefficient value of different fuel types (diesel, gasoline, kerosene) – may become a difficulty for accurate fuel level measurement in each compartment of tanker truck cistern.

→ Machinery engines using biodiesel.

Biodiesel is the fuel with changeful percent of biocomponent

Are you going to install regular capacitive fuel level sensor on all these machines, written above?

Then you will have to carry out fuel level sensor calibration using certain fuel type, taken out of the certain fuel station all the right time. It means that in case if fuel quality/type is often changed, you are to re-calibrate fuel level sensor for every certain fuel type and fill in changes in adjustments in a manual way.

We suppose you don’t need it definitely. So much the more, DUT-E 2Bio by Technoton makes it all automatically.

The main difference between regular capacitive sensors and advanced fuel level sensor DUT-E 2Bio

Regular capacitive fuel level sensors are fitted with only two measuring electrodes. DUT-E 2Bio has the third additional electrode specially designed to measure a change in permittivity coefficient value of a fuel.

Otherwords, if speaking about filling the fuel tank with another fuel type and fuel quality, DUT-E 2Bio does its best: automatically detects changes of permittivity coefficient value and corrects the results of fuel level measurement. That means, that you don’t have to re-calibrate sensors and re-configurate fuel tank anymore – now measurement inaccuracy is not more than 1%.

Advantages over other sensors

- Automatic correction of measuring results when fuel type changes

- Additional thermo-sensor, placed inside the fuel for accurate temperature correction

- Configuration via Bluetooth

- IoT Burger Technology – digital self-diagnostics, signal filtration and linearization, thermal correction, events detection “Filling”, “Theft”, “Ignition On/Off”, tank calibration table in the memory of fuel level sensor

- Interfaces: CAN j1939/S6 for transport telematics, RS-232 and RS-485 Modbus RTU, digital/pulse output

DUT-E 2Bio brings fuel theft to light in more cases than regular capacitive fuel level sensor does

Due to the existence of the third electrode fuel level sensor DUT-E 2Bio can be used to detect fuel type/quality change. DUT-E 2Bio sends to the monitoring terminal a message with readings about change in permittivity coefficient value of the fuel.

The efforts of roguish drivers to add high permittivity coefficient value liquids like kerosene, furnace oil or even grain alcohol to fuel will not go unnoticed. The owner of a vehicle fleet will receive a split-second message about interference.

DUT-E 2Bio fuel level sensor installation allows vehicle fleet owner to:

- Monitor fuel volume in the fuel tank with high accuracy aside from fuel outlets places, fuel quality/type

- Receive true to fact data about refueling and draining

- Indirectly monitor fuel quality

- Find out attempted fuel theft by discharging high-quality fuel and adding extraneous liquids to fuel in the tank

Want to know more about fuel level sensor DUT-E 2Bio? Discover new facts: