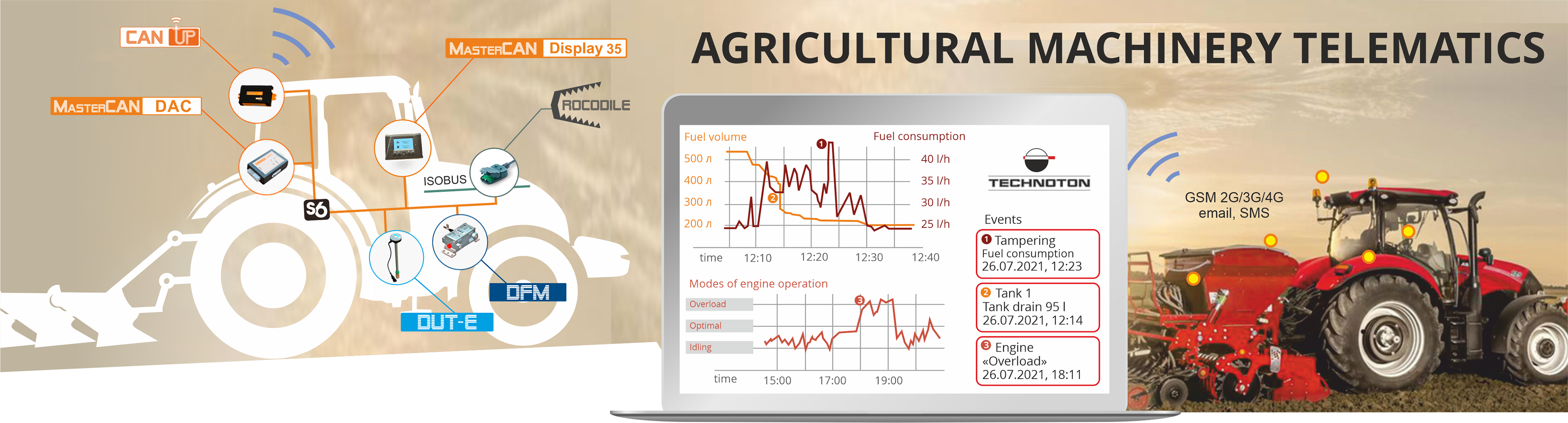

Agricultural machinery telematics — is an integral telematics solution for fuel monitoring, monitoring of operating parameters, GPS tracking and running time tracking of agricultural vehicles.

Fuel monitoring

Using DFM fuel flow meters is the most reliable way to monitor fuel consumption of agricultural machinery. Hardware is installed directly in fuel line of engine and measures actual fuel consumption with high accuracy.

The main advantages of DFM flow meters are independent power supply and possibility to provide high measurement accuracy when driving on rugged terrain or for short operation intervals.

DUT-E fuel level sensors help to monitor fuel level change in a tank – remaining volume, volumes of fill-ups and drainings.

Monitoring operating parameters

Monitoring of operating parameters allows improving quality of fleet operation and reducing maintenance costs. Fleet manager can monitor compliance of operating procedures, check operation of auxiliary and attached equipment, optimize workload modes and schedule technical inspection and maintenance based on actual condition of machines.

Parameters are collected from additional sensors, standard analog sensors (with MasterCAN DAC) and from ISOBUS with MasterCAN data converter or CANUp telematics gateway.

CANUp gateway detects over 10,000 operating parameters, and using feature of automatic J1939 /71 scanning and parsing provide telematics tecnician with a handy tool for configuring reports on machinery operation, that are further sent to a telematics server.

Machine running time tracking

DFM flow meters register running time of tractors in “Idle”, “Optimal”, “Overload” engine operation modes. This allows to keep records of duration of machinery operation and introduce employee compensation system based on actual working hours, adjust time quotas for certain works, as well as precisely monitor real engine operation hours of each unit of machinery.

Example of the project. Fuel monitoring of harvesters with DFM D differential fuel flow meters

Effects of implementing agricultural machinery monitoring

- Telematics service provides online information on the location and route of each unit of machinery, data on the cultivated area or the weight of the harvested crop.

- Data on real fuel consumption received from fuel flow counters made it possible to build an accurate fuel accounting system. Consumption rates have been optimized, fuel theft has been stopped. Fuel costs have been reduced by 30%!

- Maintenance is carried out according to actual engine operating time. All oils, filters and other consumables are changed according to their actual condition, which leads to an increase of engine’s life.