Losses from fuel theft can amount to 40% of fuel and lubricant materials financing. The problem is especially relevant for special machinery fleets, where fuel consumption and operating time of vehicles is accounted using engine hours. Mass fuel theft occurs when the lack of control takes place: the management of a vehicle fleet does not use fuel monitoring systems.

Meanwhile, drivers came up with a lot of different tricks to steal fuel: they overstate fuel consumption in trip tickets and understate fuel residue, drain the fuel from tank, refill their own oilcans instead of company-provided vehicle, make tricks with till slips and get into cahoots with fuel station operators.

It happens that drivers of the refrigerator truck turn off the icebox when driving and grab all fuel “saved”. Carried cargo can be spoiled in transit in such a case and you will have to pay the damages.

That’s why key goals of vehicle fleet, which is aiming at reducing fuel expenses, are finding out real fuel consumption and preventing fuel theft.

What happens with fuel

If the fleet is not equipped with fuel monitoring hardware, the driver can refill his oilcan (since established average fuel consumption quotas are much higher than the actual consumption is) or sell fuel, that remains, cheaper than a gas station.

In some extent, fuel level sensor can solve the problem of illegal draining fuel from the tank: the sensor provides data on refueling at gas stations and fuel drains from the tank. However, there is also a weak point here – fuel drain from the engine return line, where the drivers make hidden tie-ins. Unfortunately, a fuel level sensor cannot detect drains from the return line.

Another option is fuel monitoring using CAN bus data. The accuracy of this method is even lower, than when using a fuel level sensor, moreover, it strongly depends on the condition of engine nozzles (the algorithm calculates the flow rate by the duration of the nozzle opening). In certain instances, data in CAN bus may be corrupted or even missing.

Direct fuel consumption measurement in fuel lines is the best way to provide fuel monitoring

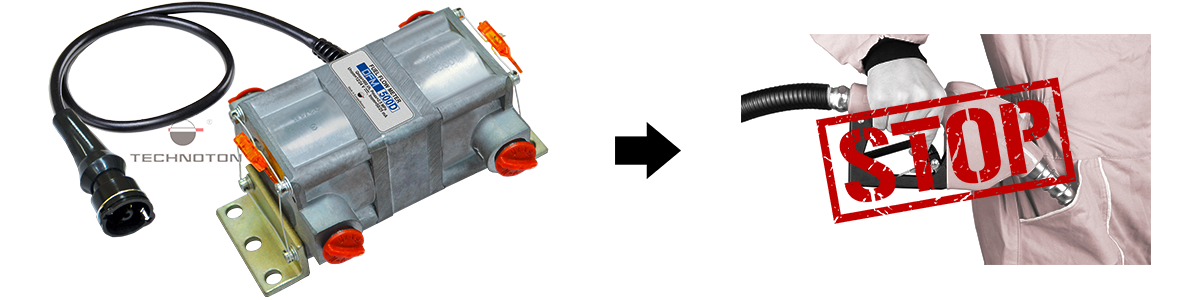

How can we prevent fuel theft even from fuel lines? The best solution is to get real fuel consumption data by using a method of direct measurement of fuel consumption in the fuel lines of engine.

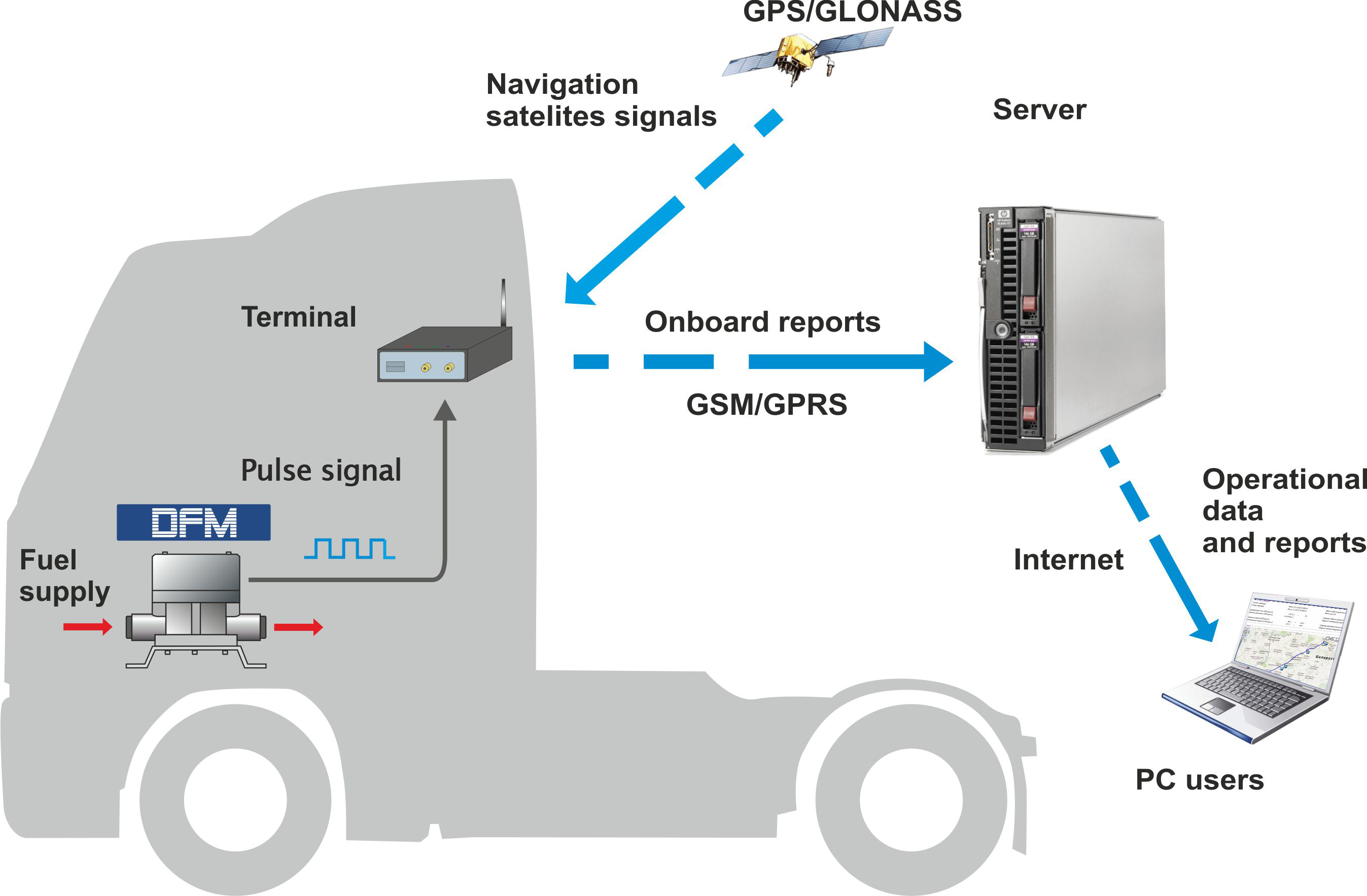

A fuel flow meter is used for this aim (also called a fuel consumption sensor, fuel meter, running flow meter). DFM fuel flow meter works with the same high accuracy no matter what type of vehicle is. Veracity of readings and data do not depend on the terrain complexity (critical for fuel level sensors), on the “age” of vehicle (old vehicles may not have CAN buses), or on the condition of nozzles (CAN bus data is based on the algorithm, which calculates instant fuel rate on as the volume of fuel injected by nozzles).

DFM flowmeter is integrated into a vehicle telematics system or stationary unit monitoring system and provides monitoring of more than 40 parameters of fuel consumption and engine operating time. The latest generation of flow meters – DFM S7 wireless fuel flow meters also transfer data to driver’s smartphone via BLE (Bluetooth Low Energy), so that the driver can choose an optimal engine operating mode to improve fuel economy.

Types Technoton’s fuel flow meter

Main specifications of DFM flow meters and fuel counters: measurement principle, hourly fuel consumption (flow rate), type of output signal.

DFM flow meters according to the measurement principle

DFM Single-chamber flow meters – are used for quite old Euro-3 vehicles and below, where modification of fuel system is possible when installing a flow meter.

DFM D differential fuel flow meters are designed for newer diesel engines fitted with fuel injection system Common Rail and engine unit injector-nozzles. The flowmeter measures fuel consumption in supply and return fuel lines and computes the difference between supply and return. It does not require any modification of a fuel system.

DFM types by flow rate

DFM and DFM D flowmeters are designed for fuel consumption measurement of highway and off-road vehicles, small sea and river watercrafts, locomotives, diesel generators and various stationary machines, where the fuel rate is 1 to 600 liters per hour.

For heavy machinery – mining, railroad trains, large river and small sea vessels and boats – DFM Marine flowmeter. Fuel rate here is 20 to 4000 l/h.

DFM Industrial is a high flow rate fuel flow meter for hourly fuel consumption from 720 to 25,000 l/h. Fields of application: large sea and river vessels, high-power diesel generator sets and boilers, fuel pipelines, petrochemical, utilities and other industrial applications (IIoT).

DFM flow meters by the type of interface

The most functional type of interface is CAN J1939/S6, which provides monitoring of more than 40 parameters of fuel consumption and engine operating time, and also reports on any attempts to tamper the readings/data and trashing of the flow counter. You may learn the complete list of Counters, parameters, and Events in DFM Operation manual.

Another type of digital interface of the flowmeter is RS 232/485. It allows integrating DFM flowmeters with industrial displays and automatic control systems (ACS) by Modbus RTU protocol.

The simplest type of signal is a pulse output signal. Unlike digital interfaces, GPS tracker or telematics units should count all the received pulses and in case some pulses are “lost”data on fuel consumption won’t get to an online vehicle monitoring system.

DFM without an output signal – autonomous fuel counters. Data is monitored according to indications on the electronic display of the hardware.

NEW: wireless fuel flow meters DFM S7 with Bluetooth Low Energy. Data on fuel consumption and engine operating time is sent to several devices using BLE-radio mode – simultaneously to telematics units and GPS trackers, driver’s or mechanic’s smartphone.

DFM cannot be influenced without a trace: main facts to the good

- If the fuel consumption rate is higher than usual, DFM registers tampering attempt.

- Magnetic interference on the fuel flow meter will not go unnoticed. When using magnets, fuel flow meter records the duration of action to “Interference” time counter.

- When someone disconnects DFM from onboard power network, the device still operates from the built-in battery and records data in its own memory up to 36 months.

- A durable metal body provides protection from climatic, mechanical and physical influences.

- Sealing of the flow meter, fuel hoses and fittings make impossible any undetectable interventions to flow meter installation place.

Take a look at top fuel flowmeters by Technoton