Fuel prices are record high. Considering that fuel expenses make 40-70% of total fleet expenses, that resource becomes even more valuable for a company and requires precise monitoring and accounting.

Ways of improving fuel efficiency and reducing fuel costs

- Optimize machinery working load modes

- Record actual engine hours and reduce machinery downtime

- Measure real fuel consumption and adjust fuel quotas

- Prevent fuel theft from fuel tank and engine lines

- Monitor engine health, detect engine failures and predict maintenance date

All these tasks can be effectively solved by adding fuel monitoring tools to already existing fleet telematics systems or by implementing stand-alone fuel monitoring systems.

Engine fuel consumption measurement

Purpose of implementation: measurement of real amount of fuel used by a diesel engine, recording actual engine hours, monitoring engine health and identifying abnormal fuel rate.

Applicable machinery: agricultural, quarrying and mining equipment, river and marine vessels, railway machinery, diesel power-generators, boilers/burners and other road and off-road vehicles.

Necessary equipment: Fuel flow meters DFM, DFM Marine or DFM Industrial. Flow rate from 1 to 25,000 liters per hour. Could be connected to already-installed telematics and GPS tracking device, or can be used as stand-alone solution (embedded display + Bluetooth data transfer)

Advantages: installation straight to engine fuel lines (feed & return), over 40 parameters, designed for tough off-road operation conditions, protected from data tampering.

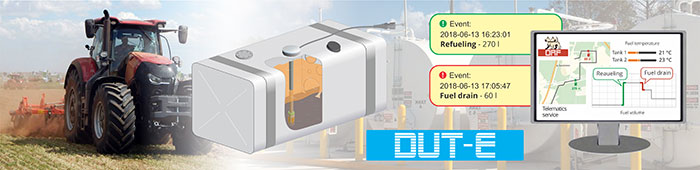

Fuel tank monitoring

Purpose of implementation: detecting current fuel level and volume in a fuel tank, detecting volumes of filling-ups and fuel draining (fuel theft) volumes.

Applicable machinery: fuel tanks of semi-trailers and trucks, tanker trucks, stationary cisterns, corporate gas stations, diesel gensets. Moreover, applicable for off-road machinery.

Necessary equipment: DUT- E fuel level sensor, DUT-E GSM or DUT-E 2Bio. Could be connected to already-installed telematics and GPS tracking device, or can be used as stand-alone solution (Bluetooth data transfer or 2G/3G technology.)

Advantages: gives precise data on fuel volume change inside the tank, allows data comparison with fuel bills/cards, helps to prevent unauthorized fuel discharge from a tank.

Combination of engine fuel consumption measurement and fuel tank monitoring, also combined with CAN bus data, gives the highest accurate result on fuel usage by a vehicle and allows

implementation of all-round control for increasing efficiency of fuel usage.