![]()

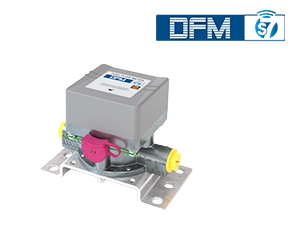

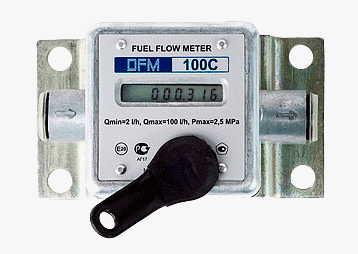

Fuel flow meter

DFM is designed for fuel consumption measurement in fuel lines of vehicles and stationary machines, also for operating time monitoring in different working modes of engine.

DFM fuel flow meter is used for consumption measurement of the following fluids:

- diesel fuel

- heating oil

- other liquid fuels and mineral oils with kinematic viscosity of 1.5 to 6 mm2/s.

DFM is a tool for direct measurement of fuel consumption, which is used as a part of GPS tracking system, vehicle telematics system or as an stand-alone (autonomous) solution for fuel consumption monitoring.

One-chamber DFM fuel flow meters are mainly intended for small and medium engines with indirect injection fuel system.

Tasks

Preventing fuel theft

Preventing fuel theft Engine testing for fuel consumption

Engine testing for fuel consumption Machine running time tracking

Machine running time trackingAdvantages of DFM

Digital Counters and built-in battery

All data is registered in digital Counters in internal memory of DFM fuel flowmeters. That ensures data safety and protection against tampering and interference by third party. Also, Counters are registering data even if external power supply is switched off. After the power supply is back all data is sent to telematics unit.

Protection against tampering

DFM has two special Counters, which register third party influence attempts on flow meter operation – “Tampering” and “Interference” Counters.

“Interference” Counter protects DFM from magnetic field impact aimed on stopping fuel consumption measurement. “Tampering” Counter registers attempts of third party to tamper flow meter data by generating artificial fuel consumption (e.g. by blowing the air through measuring chamber).

In both situations DFM will start recording duration of influence and will send alarm to a telematics unit.

Fuel consumption and operating time Counters

Fuel consumption

- Instant fuel consumption, L/H

- Hourly fuel consumption in “Forward” line

- Hourly fuel consumption in “Return” line

- Total fuel consumption, L

- Total fuel consumption in “Idling” mode of engine operation

- Total fuel consumption in “Optimal” mode of engine operation

- Total fuel consumption in “Overload” mode of engine operation

- Total fuel consumption in “Negative” mode of flow meter operation (return exceeds supply)

Engine operating time

- Total operating time, h

- Total operating time in “Idling” engine operation mode

- Total operating time in “Optimal” engine operation mode

- Total operating time in “Overload” engine operation mode

- Total operating time in “Negative” flow meter operation mode

- Total operating time of Supply chamber

- Total operating time of Return chamber

- Operating time of Supply and Return chambers in each mode of engine operation

Special

- Engine operating time in “Tampering” mode, h

- Engine operating time in “Interference” mode, h

- Current engine operation mode as per fuel consumption rate

- Fuel temperature

- Temperature correction status

- Correction coefficient value

- Battery charge

- Total CO2 Emission

- Hourly CO2 Emission

DFM types

Fuel counter (fuel meter) with LCD. Autonomous low-cost solution for fuel consumption measurement.

Fuel flow meter with output (interface) cable for sending signal to tracking unit. Efficient solution for online fuel consumption monitoring within telematics system.

Output signal cable + in-built LCD display. Combination of autonomous fuel counter and online solution for fuel monitoring within telematics system.

Information on DFM display

DFM with display allow autonomous fuel consumption measurement without data transfer to a server. This solution is mostly used for small stationary units or for small fleets operating within enclosed area.

DFM display information screens:

Total Fuel Consumption

Total Fuel Consumption counter with higher digit capacity

Engine Operation Time

Engine Operation Time in Idle Mode

Engine Operation Time in Optimal Mode

Engine Operation Time in Overload Mode

Fuel Consumption in Tampering Mode

Interference Time

Instant Fuel Consumption

Battery Charge in Percentage of the Maximum

Temperature in the Measuring Chamber

Firmware Version

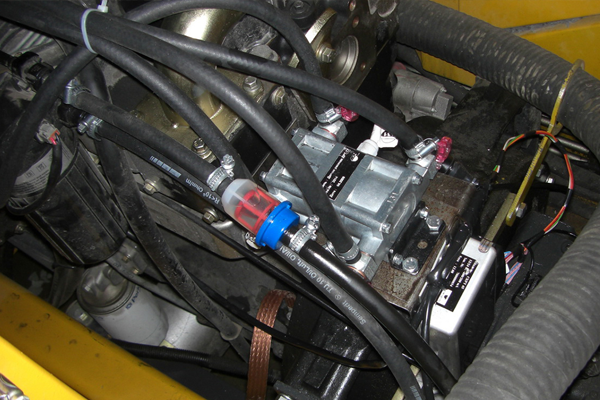

DFM installation and connection

- DFM are installed directly in fuel line of engine:

- before low-pressure pump – on “suction side”, or

- after low-pressure pump – on “pressure side”.

Exact way of installation is chosen depending on fuel system specifications. Installation schemes are described in DFM documentation. For more detailed information, please, read DFM fuel flow meters Operation Manual. For information on DFM operation together with other fuel monitoring products and CANbus tools – please refer to CAN j1939/S6 Telematics interface.

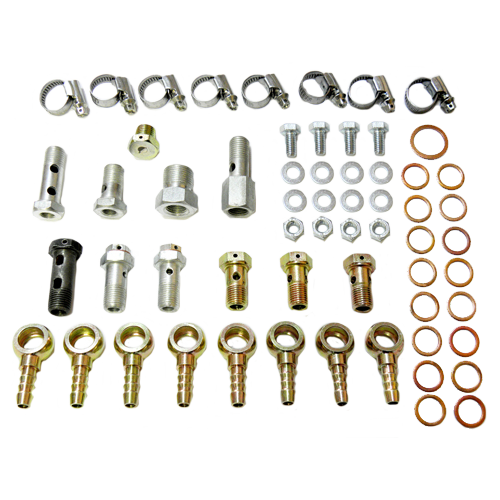

Accessories for installation of DFM flow meters

Is it possible to fool DFM?

DFM is installed directly into the fuel line of the vehicle (between fuel tank end engine) and allows prompt fuel theft detection. DFM is reliably protected from tampering and vandalism. Operation of DFM D cannot be influenced without a trace.

- Strong metal body of DFM ensures reliable protection from dust and dirt, as well as against attempts to disable the flowmeter.

- Protection from influence of strong magnetic field. In the case of electromagnetic interference, the flow meter records duration of action to special “Interference” time Counter.

- Tampering with air flow is useless! If fuel consumption rate is higher than usual, DFM registers the tampering time to special “Tampering” counter.

- High battery life. DFM fuel flowmeters can operate from the built-in battery for up to three years. When disconnected from on-board power network, DFM still records data and saves it in its own memory.

- Sealing of the flowmeter and fuel system elements. Not possible to intervene to places of flow meter installation without damaging the seals.

| Connecting thread | M14x1.5 M16x1.5 |

| Nominal pressure, bar | 2 |

| MAX pressure, bar | 25 |

| Supply voltage, V | 10-45 |

| Overvoltage protection, V | ≤100 |

| Current consumption, mA (24 V/12 V), mA | 25 / 50 |

| Operating temperature, (without/with display), °C | -40..+85/ |

| -20..+60 | |

| Ingress Protection Rating | IP 54 (IP67*) |

| Relative accuracy error per chamber, %, not more than | 1 |

*аvailable on request

| Model | Nominal bore | Start-up flow rate, l/h | MIN flow rate, l/h | MAX flow rate, l/h | Recalibration interval, l | |||||

| DFM 50 | 6 | 0,5 | 1 | 50 | 100 000 | |||||

| DFM 100 | 6 | 0,5 | 2 | 100 | 100 000 | |||||

| DFM 250 | 8 | 2 | 5 | 250 | 250 000 | |||||

| DFM 500 | 12 | 5 | 10 | 500 | 500 000 |

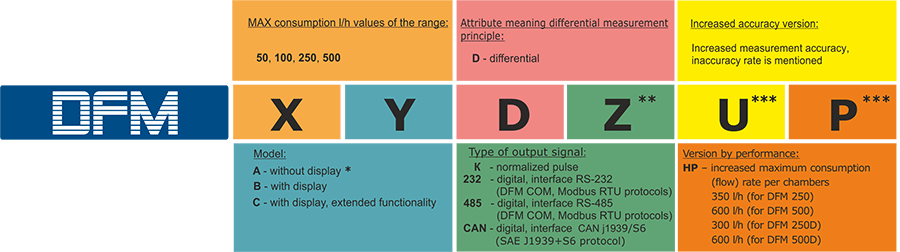

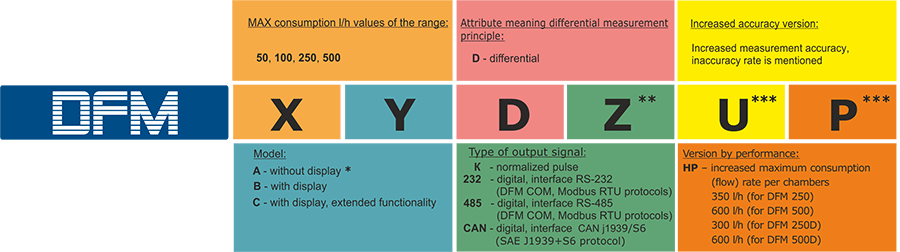

* A symbol is not specified for differential fuel flow meters.

** For autonomous fuel flow meters Z version is not used.

*** This version is delivered upon special order. Designation U is available only for one-chamber flowmeters.

Specifications

| Connecting thread | M14x1.5 16x1.5 |

| Nominal pressure, bar | 2 |

| MAX pressure, bar | 25 |

| Supply voltage, V | 10-45 |

| Overvoltage protection, V | ≤100 |

| Current consumption, mA (24 V/12 V), mA | 25 / 50 |

| Operating temperature, (without/with display), °C | -40..+85 -20..+60 |

| Ingress Protection Rating | IP 54 (IP67*) |

| Relative accuracy error per chamber, %, not more than | 1 |

Models

Model / MAX flow rate

DFM 50 / 50 l/h

DFM 100 / 100 l/h

DFM 250 / 250 l/h

DFM 500 / 500 l/h

* A symbol is not specified for differential fuel flow meters.

** For autonomous fuel flow meters Z version is not used.

*** This version is delivered upon special order. Designation U is available only for one-chamber flowmeters.